9

LEARNING TO WELD

9

MACHINE SET UP FOR THE GMAW (MIG)

PROCESS

1. See APPLICATION CHART in the OPERATION

section or Application Chart on the inside of wire

feed section door for selection of welding wire and

shielding gas, and for range of metal thicknesses

that can be welded. Also setting the proper con-

trols, Drive Roll Orientation and Output Polarity.

2 Set the “Voltage” and “Wire Speed” controls to the

settings suggested on the Application Guide for the

welding wire and base metal thickness being used.

The voltage control is marked “V” and the wire feed

speed is marked with the icon “olo.’’

3 Check that the polarity is correct for the welding

wire being used. Set the polarity for DC(+) when

welding with the GMAW (MIG) process. See

INSTALLATION section of the Operators Manual

for instructions for changing polarity.

4. Check that the gas nozzle and proper size liner

and contact tip are being used and that the gas

supply is turned on. If adjustable, set for 30 to 40

cubic feet per hour (7 to 10 l/min..) under normal

conditions, increase to as high as 45 CFH (17

I/min.) under drafty (slightly windy) conditions.

5. Connect work clamp to metal to be welded. Work

clamp MUST make good electrical contact to the

work piece. The work piece must also be grounded

as stated in the “Arc Welding Safety Precautions”

at the beginning of the Instruction Manual which is

supplied with each welder.

WELDING TECHNIQUES FOR THE GMAW

(MIG) PROCESS

Four simple manipulations are of prime importance

when welding. With complete mastery of the four,

welding will be easy. They are as follows:

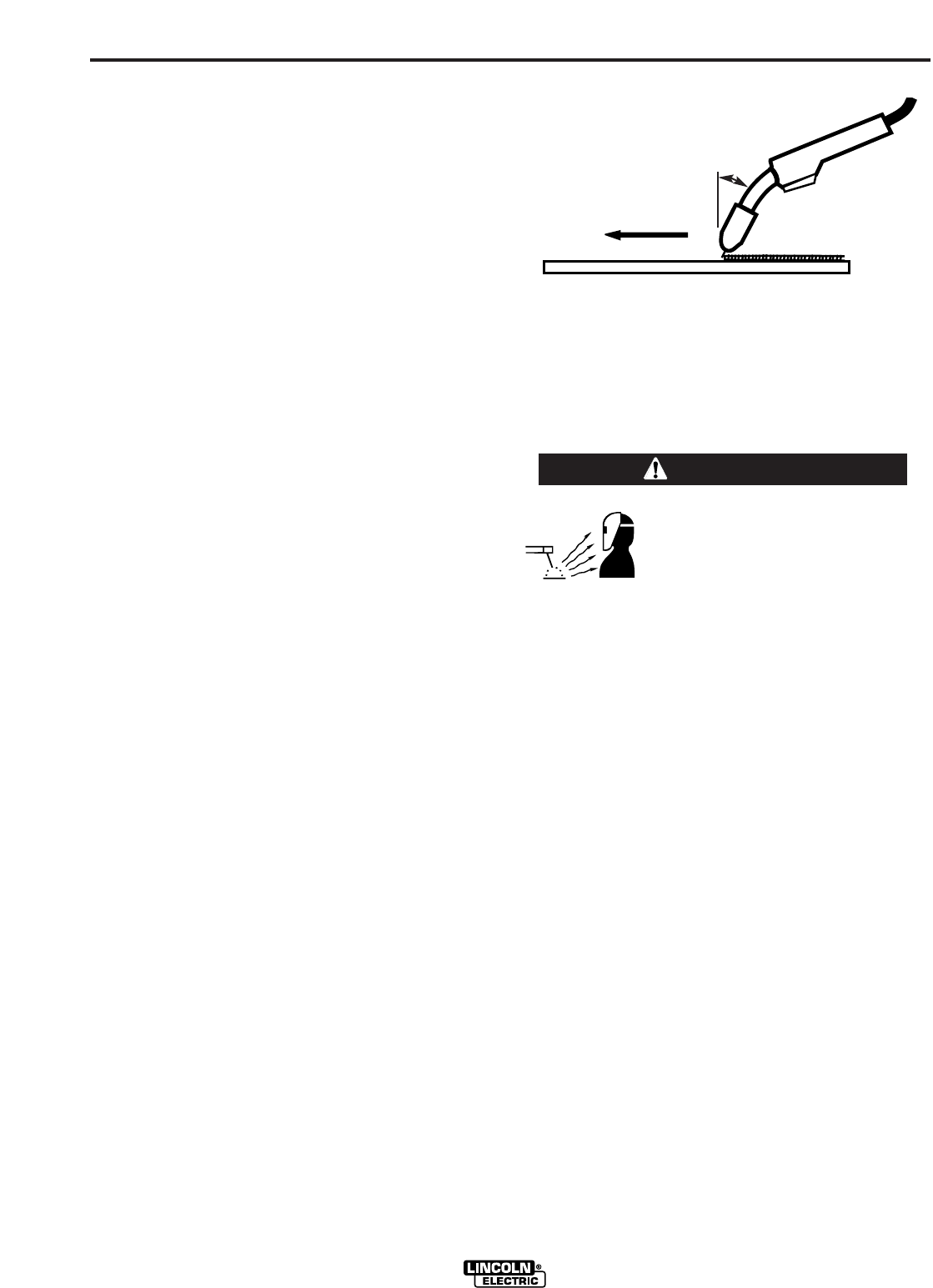

1. The Correct Welding Position

Figure 17 illustrates the correct welding position for

right handed people. (For left handed people, it is

the opposite.)

When GMAW (MIG) welding on sheet metal, it is

important to use the “forehand” push technique.

Hold the gun (of the gun and cable assembly) in

your right hand and hold the shield with your left

hand. (Left handers simply do the opposite.)

FIGURE 17

When using the GMAW process on light gauge mater-

ial, weld from right to left (if you are right handed).

This results in a colder weld and has less tendency for

burn through.

2. The Correct Way To Strike An Arc

ARC RAYS can burn eyes and skin.

When using an open arc process, it

Is necessary to use correct eye,

head and body protection.

Protect yourself and others, read

“ARC RAYS can burn” at the front

of the Instruction Manual supplied

with welder.(ANSI Z.49.1-88)

-----------------------------------------------------------------------

1. Be sure the work clamp makes good electrical con-

tact to the work.

2. Position gun over joint. End of wire may be lightly

touching the work.

3. Position face shield to protect face and eyes, close

gun trigger, and begin welding. Hold the gun so

that the contact tip to work distance is about 3/8 to

1/2 inch (10 – 12 mm).

4. To stop welding, release the gun trigger and pull

the gun away from the work after the arc goes out.

5. A ball may form at the tip end of the wire after

welding. For easier restrikes, the ball may be

removed by feeding out a few inches of wire and

cutting off the end of the wire with wire cutters.

6. When no more welding is to be done, close the

valve on the gas cylinder, momentarily operate the

gun trigger to release gas pressure, then turn off

the machine.

WARNING

15°-20°

Push