FX2N-32DP-IF Profibus-DP Interface Unit User Parameter 6

6-4

6.2 Configuring Slave Parameter

Caution:

The user parameter data and configuration of the 32DP-IF must always be consistent. To

ensure that the user parameter data and the configuration of the 32DP-IF are matching

each other, the user parameter data set should always be constructed by using the GSD file

that has been delivered with the 32DP-IF.

6.2.1 Configuring Slave Parameter by GSD file

The parameter setting of the 32DP-IF can be entirely defined using the GSD file that comes on

the disk together with 32DP-IF. For an easy adjustment of all user parameter data, the

Mitsubishi Profimap Software V2.X or a configuration software from another vendor which is

supporting extended parameter setting should be used.

Note:

In configuring 32DP-IF GSD file, first assign special function blocks, second extension I/O

units/blocks’ input data, and finally extension I/O units/blocks’ output data. The physical

placement of the module does not have to correspond with the GSD file order.

6.2.2 Configuring Slave Parameter by Programming Tool

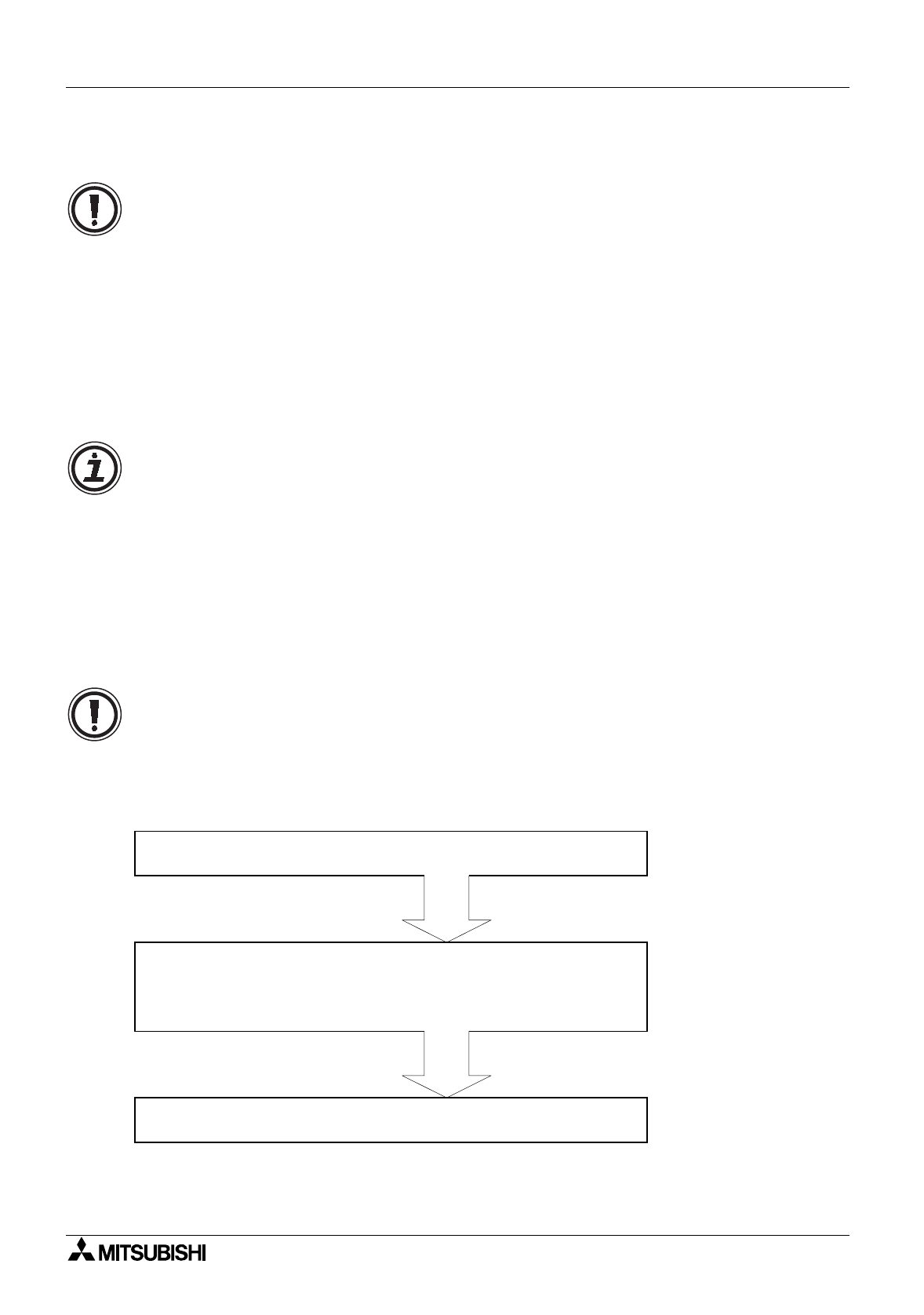

The process of defining a parameter using the programming tool is shown in Figure 6.3.

Please only use a programming tool if configuring a single special function block. It is recom-

mended to utilize the functionality of the GSD file when configuring more than one. As it is

much easier to use for this purpose.

Caution:

Any mistake in changing D200 ~ D299 can lead to a different interptetation of the Profibus-

DP data, which can result in a malfunction of the connected I/O units/blocks and special

function blocks.

Figure 6.3:Process Making Parameter Data by Programming Tool

1. Input parameter data in D200 ~ D299.

2. Turning M8020 from OFF to ON, 32DP-IF send parameter

(D200 ~ D299) extention units/blocks. After this data

furnish to be sent, M8020 is reset automatically.

3. Setting end