Manual No. 25-ULNFT2100-01; Mar, 2005 NFT 2100 CCD Fixed Mount Barcode

Scanner

Page 9

±10º

±30º

Aviod this region

1

4.

5

1

4

.

5

α

α

Readable Width or Field of View for the NFT 2100

(Field-of-View Specification Based Upon 69º Degree Sweep)

1.0"

Focal

Distance

1.4"

1.5 2.0" 2.5"

Distance from Front

of Case

25.4mm 35.4mm 38.1mm 50.8mm 63.5mm

2.6 3.1" 3.3 4.0 4.7

Field of View

66mm 80mm 83mm 101mm 118mm

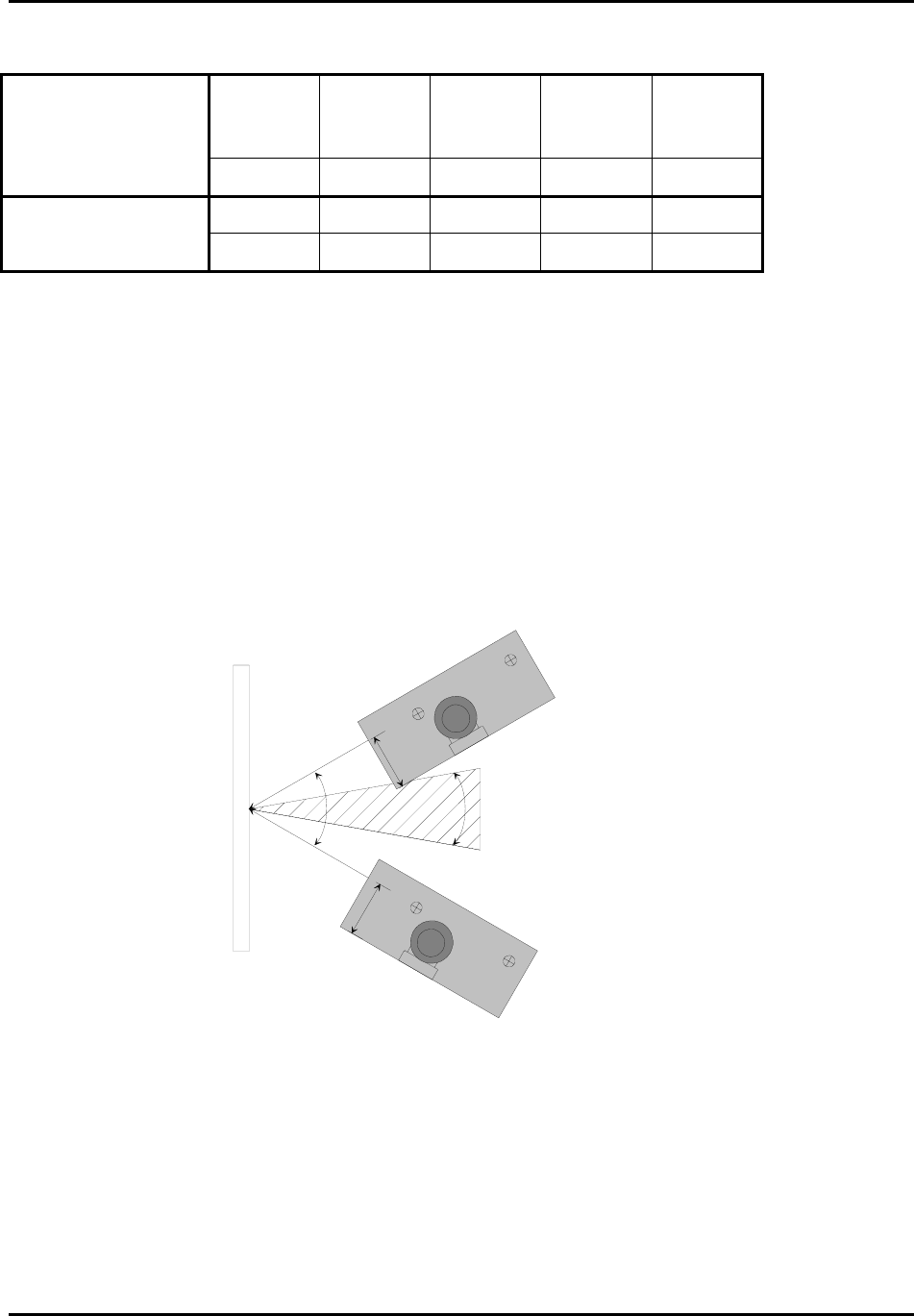

3) Avoiding Specular Reflection

Do not position the scanner at an angle that causes the LED light to be reflected directly back into the

scanner. This is called specular reflection. Too much reflected light can “blind” the scanner preventing a

good decode. For optimal performance we recommended pitching the scanner ±13º off the

perpendicular to the barcode label surface.

If the bar code label is located on a flat surface, specular reflectivity occurs in the region between ±10

degrees off perpendicular (See diagram). If the bar code label is located on a cylindrical surface, such as

a test tube, the angle of specular reflection is measured tangent to the curve. If the curved surface is

also moving, specular reflection may occur at some point along the movement. This is OK, as long as

there is sufficient regions on the test tube label where the label is out of the specular angle. The

following diagram indicates the region to avoid:

4) Quality Bar Code Labels

The quality of the bar code label can affect the scanning performance. Poor quality labels are more

difficult to decode and may result in non-reads or potential misreads. The bar code label should be

printed to specifications. This means that the bars are printed within spec, with the correct widths, no

ink spread, crisps edges and no voids. There should be a sufficient quiet zone on both end of the bar

code label. For best results, the paper or label stock should have a matte finish to diffuse light. The

print contrast signal (which is a comparison of the reflectance of the bars and the background stock)

should be as high as practical.