29

Special Cuts

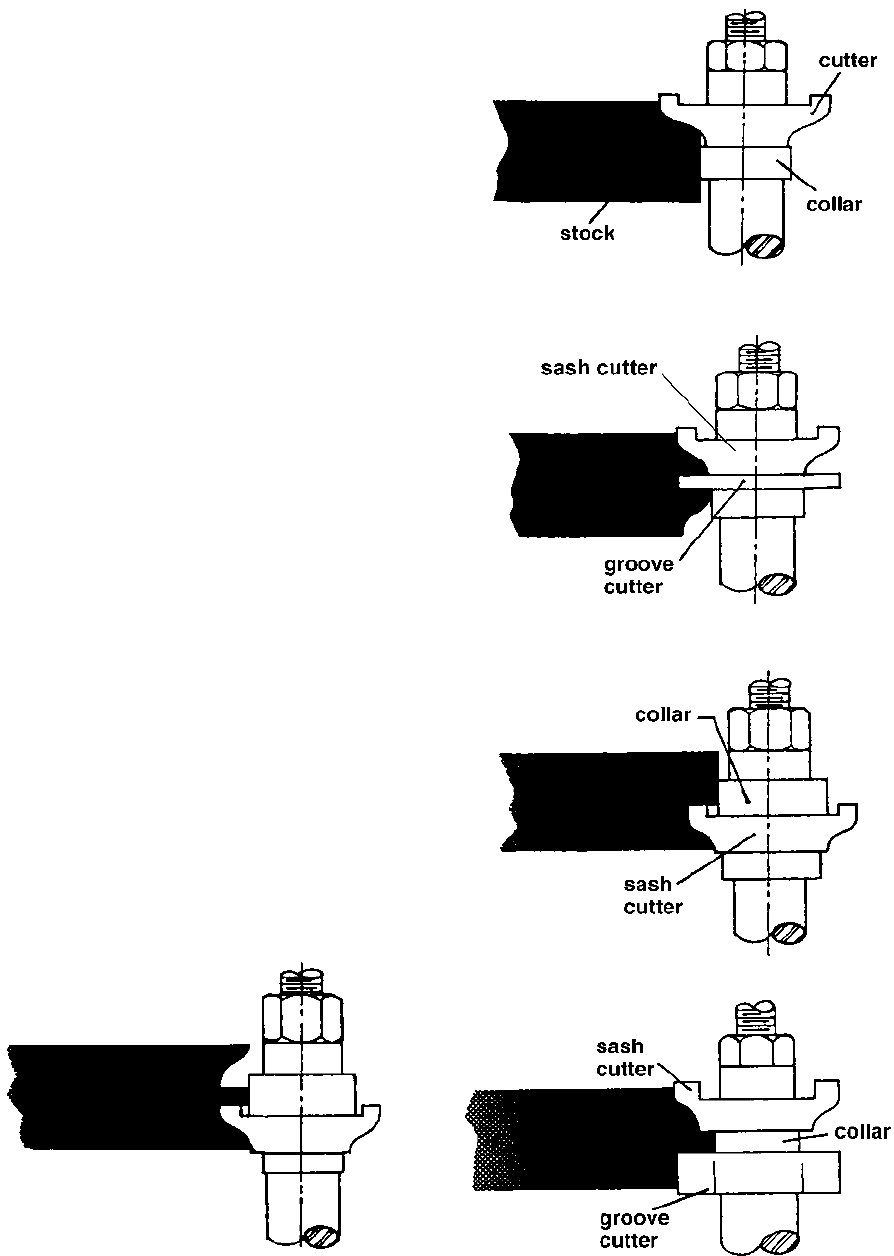

The illustrations in this section show the profile, or

section, views made by the cutter(s). The most

efficient cutters are carbide tipped to ensure clean

and long-term cutting. Small cutters may be solid

carbide, and some use inserts. Since there are

such a wide variety of choices, the operator is

limited only by his experience and imagination.

Stacked Cutters

A variety of interesting and timesaving cuts can be

made in a single setup by stacking the cutters.

When the operator stacks the cutters, extra care

should be taken to see that all parts are clean, free

of nicks and flaws, and perfectly balanced in the

stacked position.

Sash and Door Shaping

Shaping a door requires two operations.

Figure 53 shows the sash cut for the first

operation.

Figure 54 shows the stock flipped over and the

sash cutter used with a 1/4 inch groove cutter to

complete the cut.

Figure 55 shows the first shaping cut with the sash

cutter for the matching door stile sash.

Figure 56 shows the same cut with the stock

flipped over.

Figure 57 shows the first shaping cut for a window

sash stile utilizing a sash cutter, collar, and a 1/2

inch groove cutter.

Figure 56

Figure 53

Figure 54

Figure 55

Figure 57