30

Fi

g

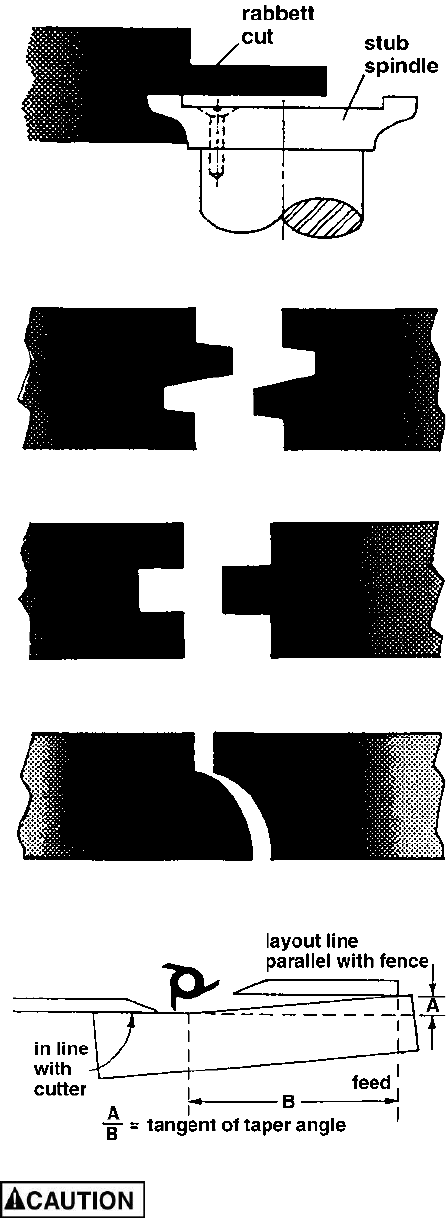

ure 58 shows BOTH cuts required for a window

sash rail end. The first operation at top is a rabbet

cut made with a groove cutter. The second

operation is performed with a stub spindle and

buttonhead screw.

Butt Joints

All butt-type joints require both work-pieces to be

perfectly square and straight-edged.

Glue Butt Joint

To perform a glue butt joint, both fences are kept

inline and adjusted for a depth of cut (Figure 59).

The cuts on both work-pieces are part-edge cuts

which do not reduce the stock width during the

cutting procedure. When shaping the two

workpieces, one is fed top-side up; the other is fed

bottom-side up.

Tongued Joint

Similar to the glue joint, both fences are kept in-line

for the tongued joint and adjusted for a 1/4 inch

depth of-cut with no reduction in stock width. With

this joint, however, both work-pieces are fed with

the same side up as shown in Figure 60.

Drop Leaf Joint

When shaping a drop-leaf joint as shown in

Figure 61, the leaf workpiece is shaped with a

Drop-Leaf Bead cutter; the table workpiece is

shaped with a Drop-Leaf Cove cutter.

With this type joint, the whole edge of both

workpieces is shaped, same-side up, and

allowance made for a 1/16 inch reduction in width.

Adjust the in-feed fence to reduce the workpiece

width by 1/16 inch, and adjust the out-feed fence to

compensate for stock removed.

Taper Cuts

Taper cuts can be made by offsetting the fences

for the amount of taper desired, or with a layout

line on the stock which can be paralleled to the

infeed fence as shown in Figure 62.

Start the cut by holding the stock against the

infeed fence and swinging it into contact with the

outfeed fence just past the cutterhead. As the cut

is started, transfer pressure to hold the workpiece

against the outfeed fence, and continue feeding

the workpiece through. After the first cut, the

fences will have to be readjusted in order for the

second cut (parallel cut) and the final depth-of-cut

to remain true with the taper.

Figure 58

Figure 59

Figure 60

Figure 61

Figure 62

Do not use the standard fence

for short work (12 inches or less in length on

the side to be cut). Instead, use a miter gauge

or special fixture to avoid losing control of the

workpiece.