Page 13

• Long Operating Life. Sony required materials and operating structures

that could withstand thousands of hours in the high heat of a large-venue

projector without performance degradation.

• Minimum Artifacts. Some projection systems tend to introduce artifacts

not present in the original picture. Sony sought to reduce artifacts.

• Practical Manufacturing Process. Despite their performance

advantages, LCoS panels continue to frustrate companies that would

mass produce them. As a major consumer electronics manufacturer,

Sony absolutely required a microdisplay suitable for mass production.

• Scalability. We wanted a system that could support both small,

affordable panels for mass-produced consumer televisions and large

panels for Large Venue and Digital Cinema projection.

Sony found the answers in an all-new approach to reflective liquid crystal

technology: the SXRD panel. The acronym is short for Silicon X-tal Reflective

Display, where "x-tal" is engineering shorthand for "crystal."

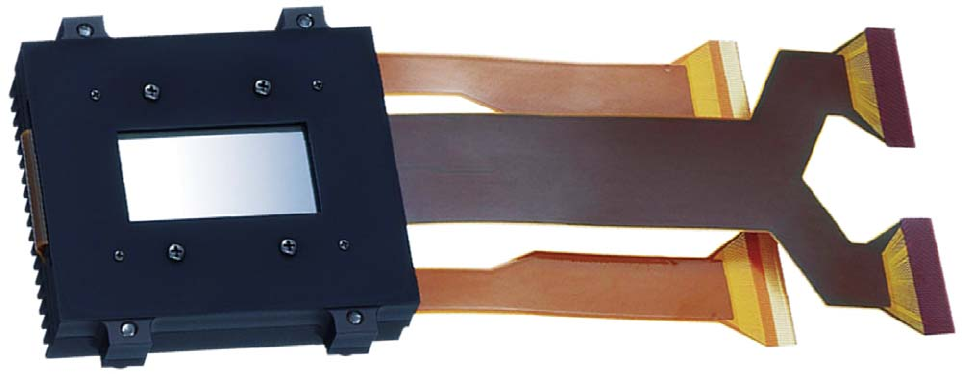

More than 8 megapixels on an inch and a half of silicon, this is Sony's 4K

SXRD panel. The four input ribbons correspond to the projector's four

input slots and the four 2K quadrants of the panel.

SXRD microdisplay basics

All liquid crystal displays use three elements to modulate the passage of

light: a pre polarizer, a rotation medium and a post polarizer. In H-LCD

microdisplays, these three elements form a sandwich. At the entrance, the pre

polarizer aligns the light. In the middle, the liquid crystal rotates the required

parts of the light path. At the exit, the post polarizer blocks the light not required

to make the picture.