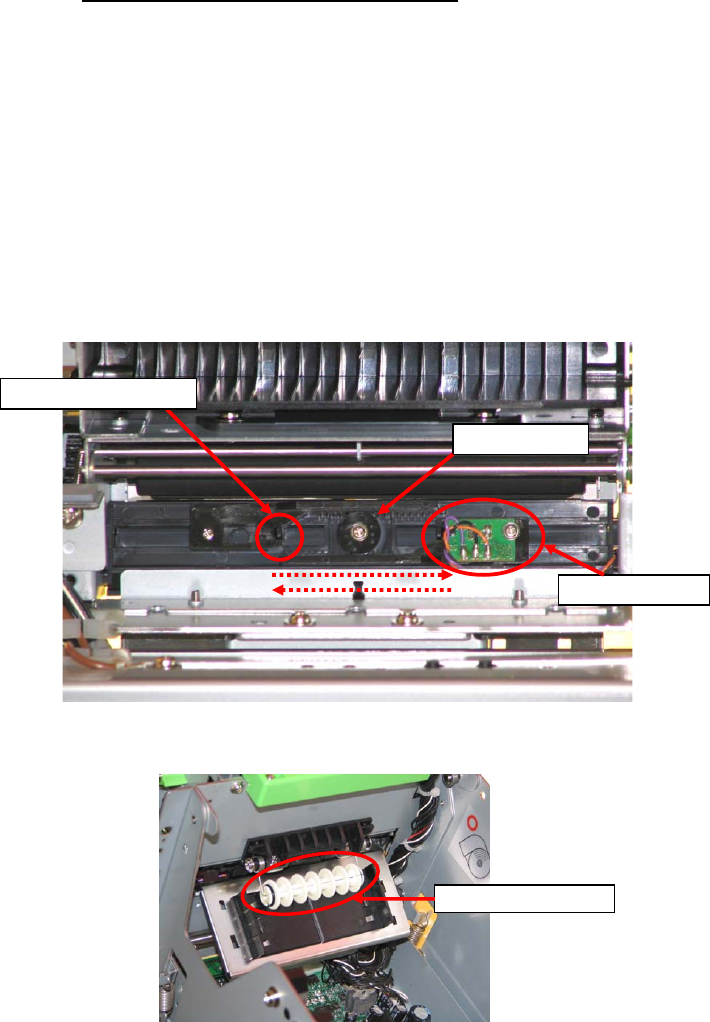

TUP900 Paper Feed Sensor Adjustment – See photos below

This is a multi-step process:

1. Ensure that the paper is loaded on the spindle and that the two black plastic

sleeves are positioned on either side of the paper roll in order to keep the roll

centered on the spindle and from sliding left or right.

2. Power on the printer. If the paper does not automatically feed through the

presenter on power up then you will see a solid red light on LED 2 that will start

flashing after a second or two following power up. At this point the paper width

sensor needs an adjustment.

3. Power off the printer.

4. Remove the printer from the kiosk and turn it upside down to locate the Paper

Feed Sensor assembly. Make sure the Presenter is closed.

Cogged Wheel

Black Raised Positioner

Paper Feed Senso

r

5. Turn the printer over and position the end of the paper under the rear white feed

rollers and slide the paper into the paper feed area.

White Feed

Rollers

Paper Feed Sensor Adjustment:

6. Power on the printer. You will see 2 lights, a solid green power LED 1 and a solid

Red error light on LED 2 that will start flashing after a second or two following

power up. If the printer needs a fine adjustment of the Paper Feed Sensor, turn the

printer over in order to access the sensor assembly.

7. Slowly slide the black raised positioner on the paper feed assembly until the red

error LED2 stops flashing and the paper begins to feeds *Warning: Over

adjustment will cause the paper to snag on the sensor.

8. At that point the paper width sensor is set properly to detect the new paper and the

printer is ready to be installed in the kiosk.

7

Star Micronics America, Inc., 1150 King Georges Post Rd, Edison, NJ 088371

Date: 12/3/2007