BJ5-620 Maintenance 44 of 73

Working on the Cutting Knives

Correctly setting and mounting the cutting knives is important when working with

shredders to ensure efficient and economic function.

Replacing and Checking the Cutting Knife Mountings

Certain machine parts are subject to stress during operation as a result of vibrations that

can lead to loosening of the screw connections. It is absolutely necessary to check the

cutter and bed knife mounting screws in accordance with the maintenance plan.

1. Tighten the mounting screws on the cutters and bed knives using a torque

wrench (check required torque for the screw size). The required torque

for the knife fixing bolts is 355 Nm.

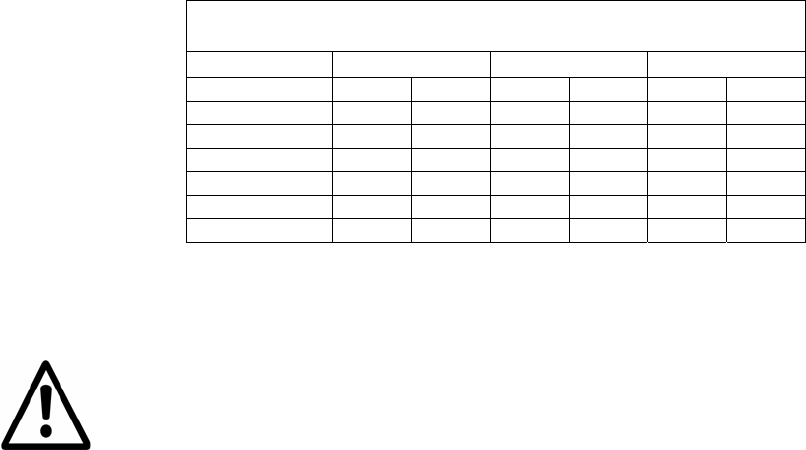

NOTE: You can find out the required torque from the following table. Tightening

capacity decreases for screws when loosened and tightened again several times.

New screws of the same material quality must replace the cutting knife

mounting screws after they have been loosened and tightened several times.

Checking the Condition of the Cutters

WARNING! Danger of cutting caused by sharp knives at all times—even when rotor is at

standstill. Serious Injury especially to the hands and fingers can occur. Wear protective

gloves!

The cutting knives become blunt after a certain number of operation hours; they should

be checked regularly. Using blunt knives can affect the efficiency and performance of

the machine in the following ways:

• Decreased shredding capacity.

• Increased current consumption of the drive motor.

• Inexact cut.

• Overheating of the shredded material.

Torque

Bolt type Grade 8.8 Grade 10.9 Grade 12.9

Nm lbf ft Nm lbf ft Nm lbf ft

M8 25 18.4 35 25.8 41 30.2

M10 49 36.1 69 50.9 83 61.2

M12 86 63.4 120 88.5 145 106

M16 210 154 295 217 355 261

M20 410 302 580 428 690 508

M24 710 523 1000 737 1200 885