PAGE 21

206-3634

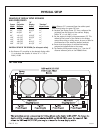

SYSTEM ALIGNMENT

Mount Bracket Center

11" from Front Panel

Under the Green CRT

Center

11

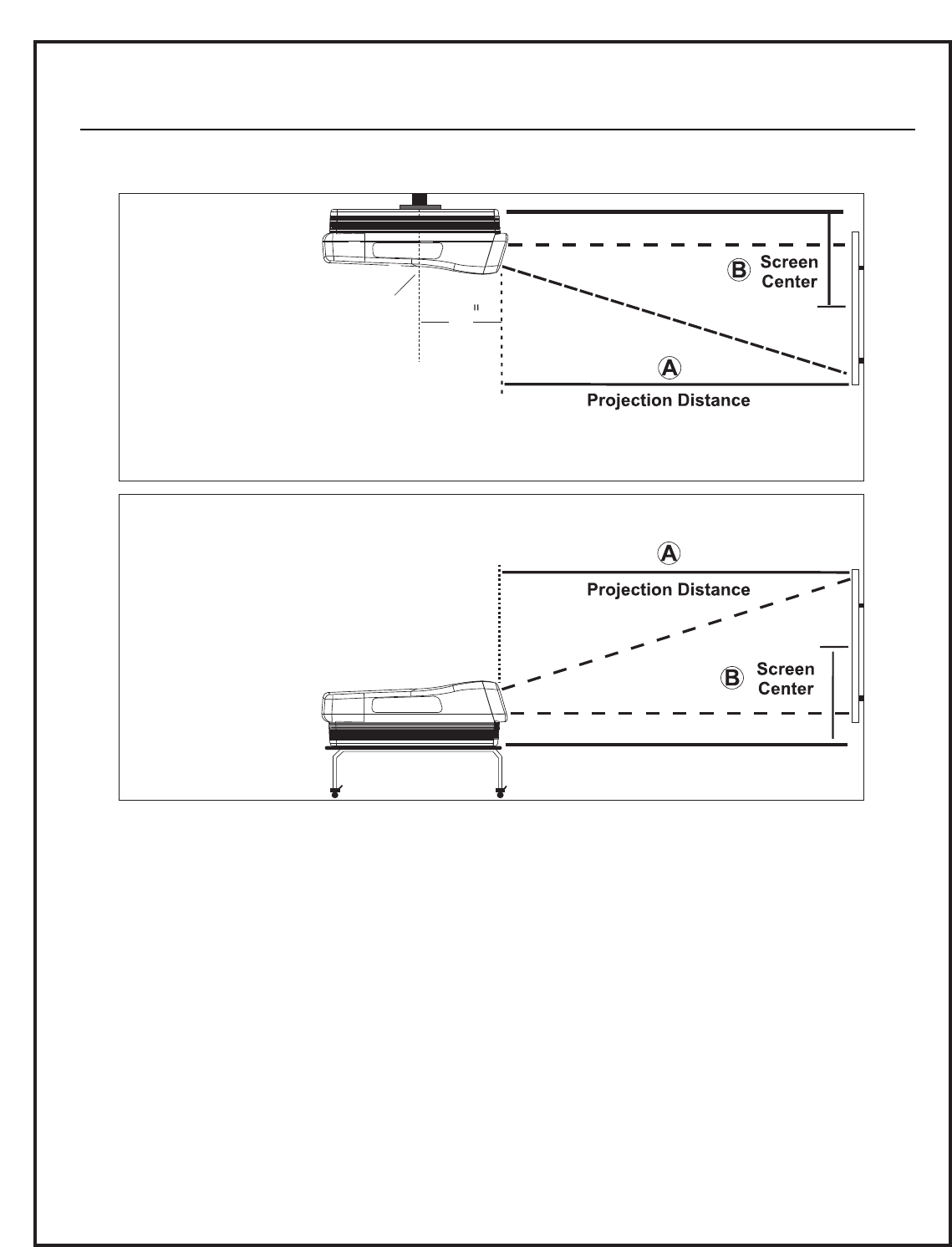

III. PRELIMINARY ALIGNMENT SETUP

The following procedures are intended for complete

“Geometry/Convergence” setup. Use the customer’s signal for

doing phase, and size adjustments. You can use the internal

patterns for shape and convergence if the customer signal

sources do not have a cross-hatch pattern.

If you are realigning a single CRT, due to replacement, or doing

alignment touch up, perform the following steps as needed.

1. Yoke Tilt Alignment

Use a cross-hair or cross-hatch pattern. Monitor only the cen-

ter- most horizontal line of the pattern to check yoke tilt.

Do not use SW9501, on the 9-1510 module, to disable conver-

gence. The vertical circuit is not disabled, only the horizontal is

disabled.

a. Set Horizontal DC centering to “0” (red, green, blue).

b. Set Vertical DC centering:

Floor: Red = -30; Green = -20; Blue = -30.

Ceiling : Red = 30; Green = 20; Blue = 30.

c. In geometry mode and convergence mode (green, red, and

blue) set “SKEW” H = 0 and “SKEW” V = 0.

d. Adjust the Red, Green, and Blue yokes for no horizontal

tilt or twist.

2. Yoke Ring Magnet and Astigmatator Alignment

Verify Only - This is not a normal field adjustment.

The astigmatator assembly should be mounted 62.5 mm from

the video output module (from the front edge of the video out-

put module to the six pole rings). Refer to figure on page 24.

Astigmatator Alignment Verification Test

Adjust for the best electrical and mechanical focus.

Continued on next page

Text continued from page 18