9/92

1-3

MODEL 2100 OVERHEAD PROJECTOR

PRINCIPLES OF OPERATION

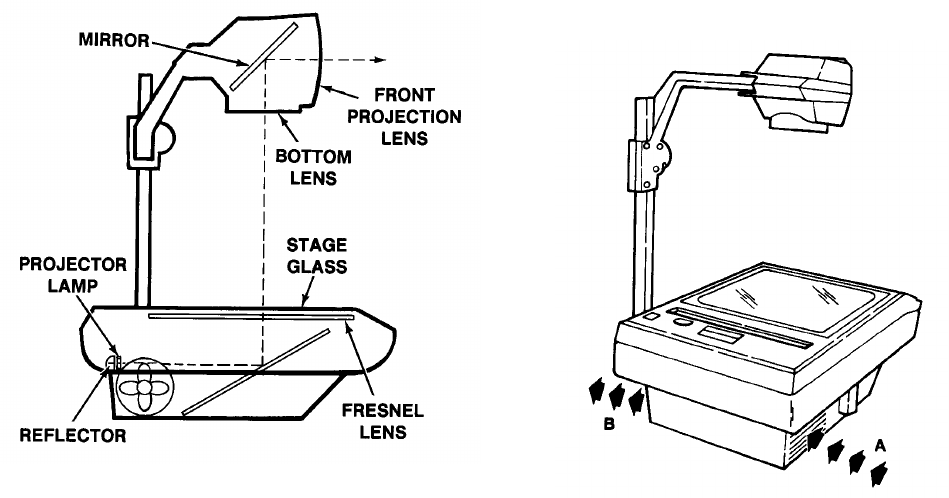

Optics (See Figure 1-2)

The light source for the Overhead Projector

is 275 watt, 24 volt, Tungsten Lamp listed

as ANSI Code FNT and rated at 75 hours.

An external reflector is needed with this

lamp.

Care should be exercised to prevent

excessive vibration or jarring of the

projector when the lamp is on. The lamp

filament becomes more brittle at the

operating temperature of the projector and

shocks may cause premature failure of the

lamp.

The glass envelope should not be touched

by the fingers when inserting the lamp in

the lampholder. Oils on the skin may

combine with the glass to form blisters

which also will shorten the life of the lamp.

The Fresnel lens, located above the lamp

and directly beneath the projection stage, is

a condensing lens which consists of a

series of concentric rings, each of which

has a surface curvature similar to that of a

thick smooth lens. The Fresnel lens is made

of plastic and may be severely damaged if

the fan is stopped or the paths of cooling air

blocked. Proper alignment and direction of

the Fresnel lens is essential in order to

maintain the resolution and brightness

specifications for the projector.

The stage glass provides a convenient flat

surface for placing transparencies and other

materials to be projected. Because the light

passes through the stage, these projection

materials must be transparent.

There are two (2) different projection head

assemblies available for the projector. One

is an Open Triplet Head with focus

correction which has a triplet lens and front

surface mirror and the second a closed

Doublet Head which has one or two

condensing lens(es) and a front surface

mirror. The projection head is located

directly over the center of the Fresnel Lens.

The projector is focused by raising or

lowering the projection head.

Proper alignment of the optical components

and a clean machine are essential if the

maximum operating capabilities of the

overhead projector are to be realized.

Cleaning and alignment procedures are

discussed in Sections 2 and 4 inclusive.

Cooling (See Figure 1-3)

Cooling of the overhead projector is

accomplished by a motor-driven fan located

next to the lamp housing. The cooling air

enters the projector through opening “A”

and exits through opening “B.” (See Figure

1-3) It’s important that the flow of cooling air

not be restricted either by placing projector

too close to a wall (about one foot

clearance is necessary) or by leaving

foreign objects inside the projector.