Chapter 7

7-14

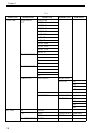

c) ADJUST

Performs adjustments and prints the adjustment and check patterns necessary for adjusting the printer parts.

1) PRINT PATTERN

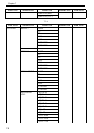

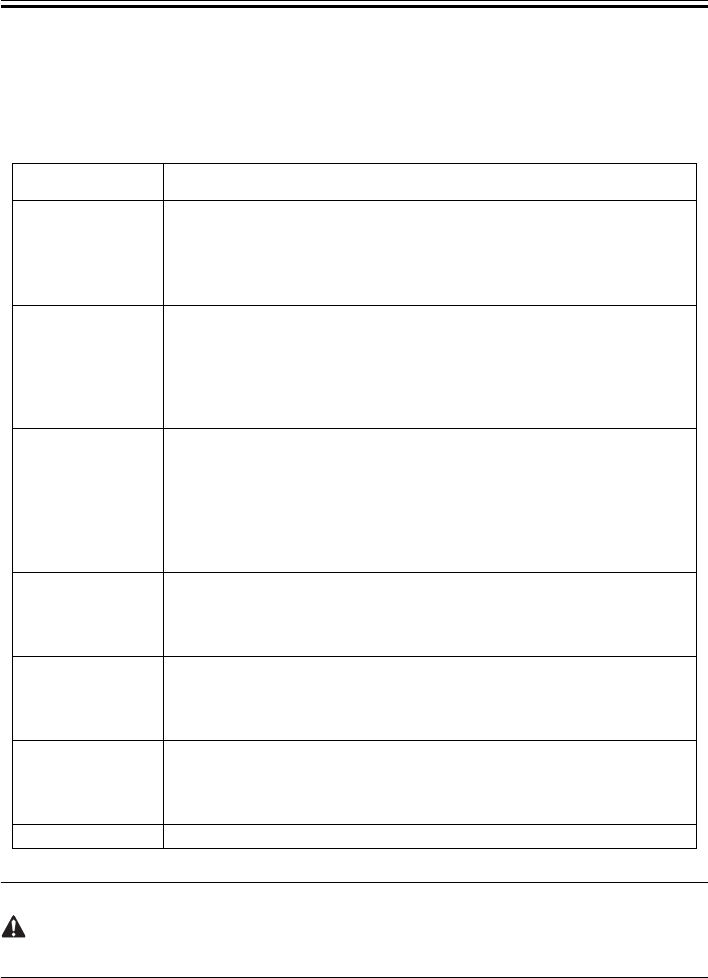

T-7-12

SENSOR CHECK are intended for factory adjustment purposes.

No adjustment by service personnel is required.

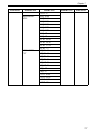

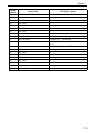

2) HEAD ADJ.

Set or initialize the registration adjustment values of each printheads.

Display Description

NOZZLE 1 Prints the nozzle check pattern by single direction/ single pass without using the

non-discharging back up.

It is used to check for the non-discharging nozzles.

- Media size: A4

- Media type: any

NOZZLE 2 Print a 100% solid print pattern (used to check the ink reaction that cannot be

checked with "NOZZLE 1") in the single path direction. Use this method when

checking blocked nozzles.

- Use paper with a height equal to or longer than that of A4-sized paper (in portrait

orientation).

- Any media type is acceptable.

NOZZLE 3 Print a 100% solid print pattern (used to check the ink reaction that cannot be

checked with "NOZZLE 1") in the single path direction. Use this method when

checking blocked nozzles. (The print drive control method is different from that for

"NOZZLE 2".)

- Use paper with a height equal to or longer than that of A4-sized paper (in portrait

orientation).

- Any media type is acceptable.

OPTICAL AXIS Prints the pattern and adjusts the optical axis of the multi sensor.

For details, refer to "Disassembly/Reassembly" > "Adjustment and Setup Items" >

"Procedure after replacing the carriage unit or multi sensor".

- Media type: photo glossy paper

LF TUNING Carry out automatic correction of eccentricity of the feed roller. For more details,

refer to "Disassembly/Reassembly" > "Adjustment and Setup Items" > "Procedure

after replacing the feed roller and reed roller encoder".

- The media type is "gloss photo paper".

LF TUNING 2 Carry out manual correction of eccentricity of the feed roller. For more details,

refer to "Disassembly/Reassembly" > "Adjustment and Setup Items" > "Procedure

after replacing the feed roller and reed roller encoder".

- The media type is "gloss photo paper".

SENSOR CHECK * For Factory