Liebert XD Cooling Modules—Liebert XDO, Liebert XDV, Liebert XDH and Liebert XDCF

55

4.11 Liebert XDC Standard Features

• Compressors—Scroll with a suction gas cooled motor, vibration isolators, thermal overloads, man-

ual reset high-pressure switch and pump down low-pressure switch.

• Refrigeration System—Dual refrigeration circuits each including liquid line filter dryers, refriger-

ant sight glass with moisture indicator, electronic control valve, adjustable externally equalized

expansion valves and liquid line solenoid valves.

• Heat Exchanger—Brazed plate design with interwoven circuiting constructed of stainless steel

plates, copper brazed. PUMPS Centrifugal type, end suction, canned rotor design.

• Standard Control Processor—The standard control system is microprocessor-based with an exter-

nal LCD numerical display to allow observation of specified adjustable functions. Normal operat-

ing conditions are indicated on the LCD panel, which is mounted either on the unit or on the wall,

depending on application details (see user manual, SL-16671). The control system also monitors

unit operation and activates an alarm when any of the specified factory preset conditions are

exceeded.

• Cabinet and Frame—Custom powder painted steel panels. A hinged control access panel opens to

a second front panel, which is a protected enclosure for all high voltage components. Frame is con-

structed of 14 gauge heliarc welded tubular steel and painted using an auto-deposition coating

system.

4.11.1 Liebert XDC Optional Features

• Water / Glycol Condensers—A water/glycol floor stand condenser option is available for heat

rejection requirements. The water/glycol floor stand can be located beneath the XDC unit or

installed nearby.

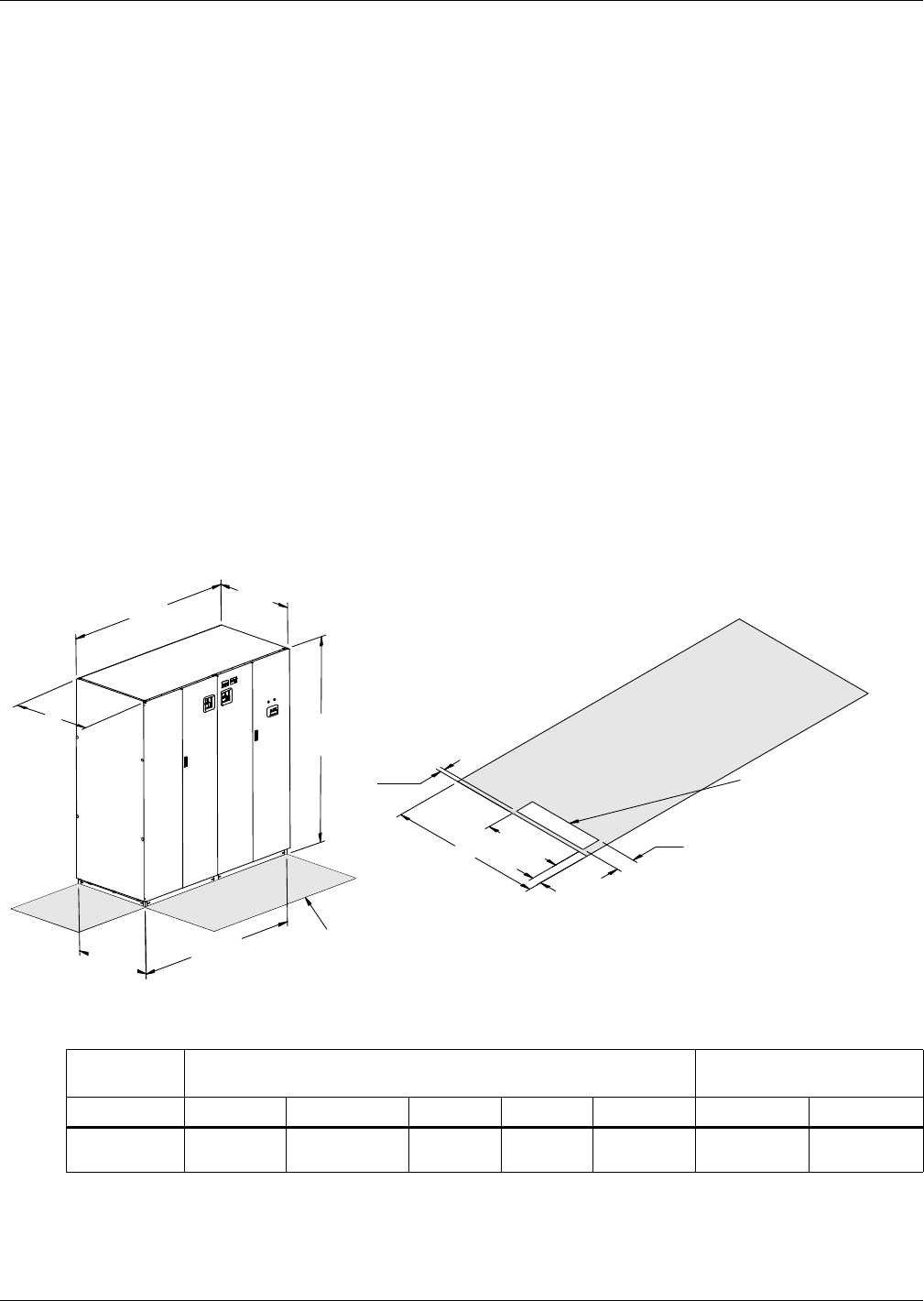

Figure 56 Liebert XDC dimensional data

Table 24 Liebert XD Chiller dimensions, weight

Air Cooled

Model Dimensional Data, inches (mm) Shipping Weight, lb (kg)

50/60Hz A B C D E Domestic Export

Liebert

XDC160

74 (1880) 34 (864)

33-1/8

(841)

33 (838) 72 (1829) 1945 (882) 2093 (949)

* Dimension does not include the bezel of the disconnect switch.

C

D

B

Overall

5"

(127mm)

17"

(432mm)

1"

(25.4mm)

2"

(51mm)

78"

1981mm

A

Overall

Shaded areas indicate a

recommended clearance

of 34" (864mm) for

component access.

D

Unit

Base

E

Unit Base

Unit Dimensional Data

Floor Cutout Dimensions

DPN000768

Page 2, Rev. 6

Recommended

Minimum Hot Gas

Supply & Liquid Return

Piping Opening