GBC 620os Operation Manual

© 2007 General Binding Corporation Page 10

FEATURES/ACCESORIES GUIDE

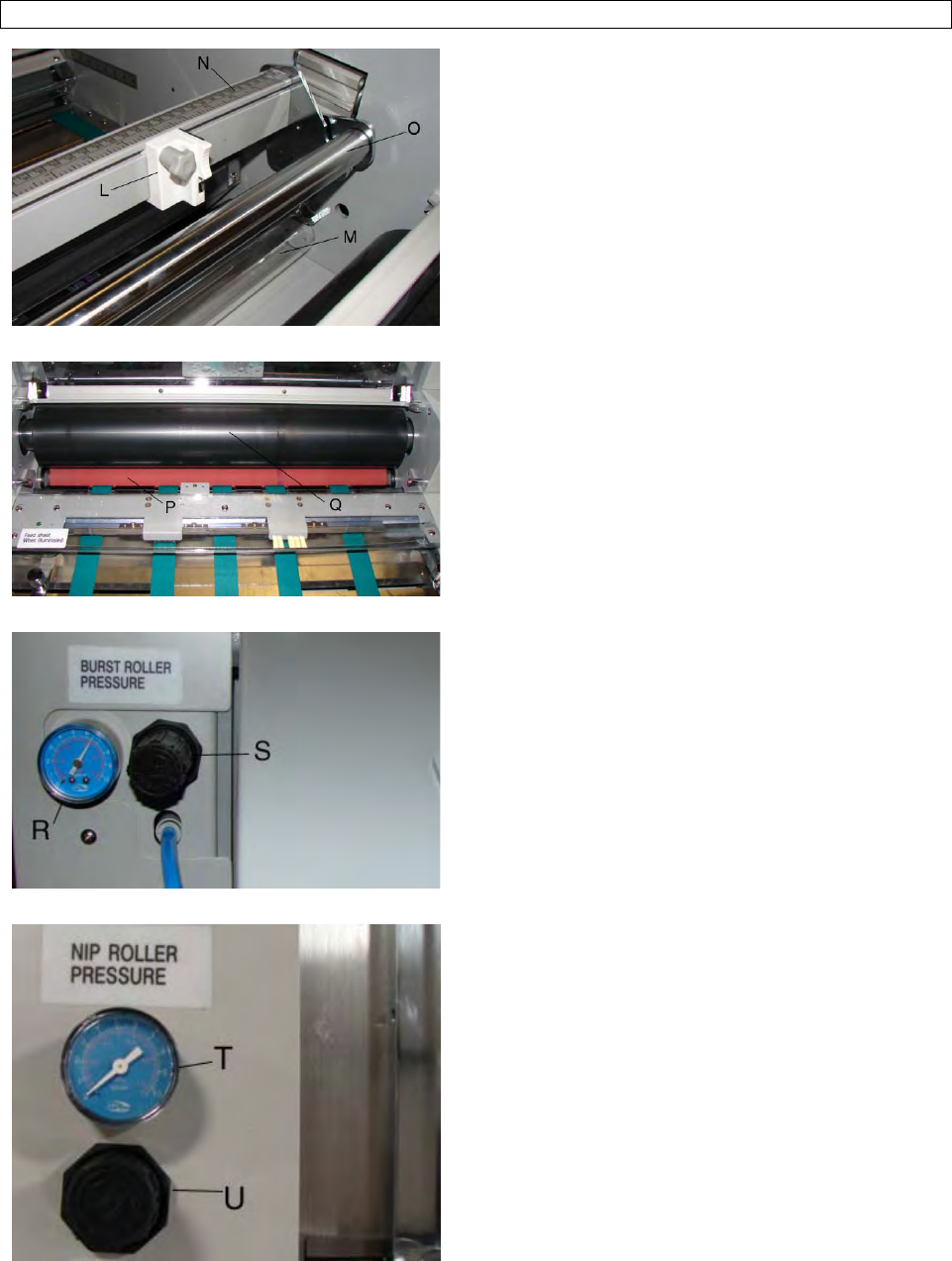

Figure 5

Figure 6

Figure 7

Figure 8

IN-LINE SLITTERS

(Fig. 5– Item L)

The In-Line Slitters allows the operator to slit film before

it passes through the Main Rollers. The trimmed waste can

then be attached to the Rewinder Tube and disposed of

later.

COOLIN TUBE

(Fig. 5– Item M)

The Cooling Tube gives the operator the option of cooling

the media after it passes through the Main Rolls. This can

be activated on the Main Display Panel.

GUIDE RULER

(Fig. 5– Item N)

The Guide Ruler helps the operator align the Slitter

Blades accurately and helps align images to the film.

IDLER BAR

(Fig. 5– Item O)

The Idler Bar is used to give the film more dwell time over

the Heat Roller. It also assists in smoothing out the film

before it enters the Nip.

NIP ROLLER

(Fig. 6– Item P)

The Nip Roller is a silicone roll and does not heat up. The

Main Heat Roller is lowered onto the Nip Roller to create

pressure needed for laminating.

MAIN HEAT ROLLER

(Fig. 6– Item Q)

The Main Heat Roller is Teflon coated & heats up to the

desired set temperature activating the film for lamination.

BURST ROLLER PRESSURE GAUGE

(Fig. 7– Item R)

The Burst Pressure Gauge indicates how much PSI is

being supplied to the Burst Rollers. Different gages of

paper may require changes to the pressure of the Burst

Roller.

BURST ROLLER PRESSURE GAUGE KNOB

(Fig. 7– Item S)

The Burst Roller Pressure Knob allows the operator to

increase or decrease the amount of PSI supplied to the

Burst Roller.

NIP ROLLER PRESSURE GAUGE

(Fig. 8– Item T)

The Nip Roller Pressure Gauge indicates how much PSI

is being supplied to the Main Heat Roller and Pull

Rollers. Different gages of paper may require changes to

the pressure of the Main Heat Roller.

NIP ROLLER PRESSURE GAUGE KNOB

(Fig. 8– Item U)

The Nip Roller Pressure Knob allows the operator to

increase or decrease the amount of PSI supplied to the Nip

Rollers, and the Pull Rollers.