GBC 620os Operation Manual

© 2007 General Binding Corporation Page 9

FEATURES/ACCESORIES GUIDE

Refer to the following pages for detailed Features.

information on the

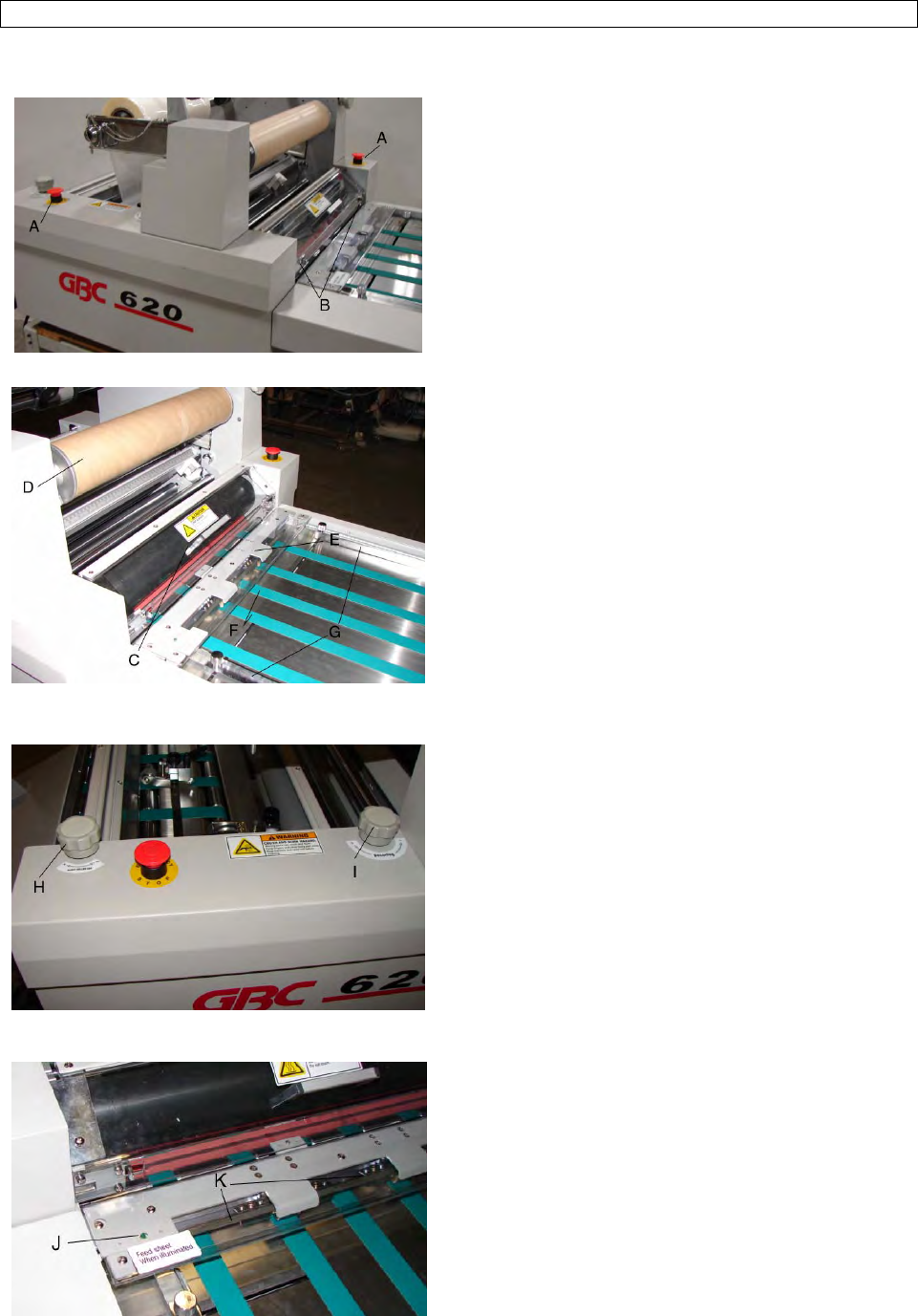

Figure 1

Fig

ure 2

Fig e 3

ur

Figure 4

ement. To disengage, turn the EMERGENCY

atches ensures that

serted properly and if not

perate.

afety Shield prevents entanglement,

inadvertent contact with the Heat Roller.

is used to take up any film that is being slit

Slitters.

he Nip. It

cording to the paper size selected on the

an even and accurate overlap.

images into the Feed Gate and

mG)

ccurate

and film being used, the

to assist in the

mount

ator. The Decurling Bar is

lls and the Pull Rolls.

te when the next sheet

eed Table. Sheets should not be

inated.

The Feed Gate Stops can be adjusted up, down, and left to

right to accommodate various media paper thicknesses.

EMERGENCY STOP BUTTONS

(Fig. 1– Item A)

There are two EMERGENCY STOPS on the laminator.

One is located at the rear of the machine and the other is

located on the front.

To engage, press any EMERGENCY STOP to stop the

roller mov

STOP clockwise after the emergency condition has been

resolved.

FRONT SAFETY SHIELD INTERLOCK LATCHES

(Fig.1-Item B)

The Front Safety Shield Interlock L

the Front Safety Shield is in

achine will not oengaged, the m

FRONT SAFETY SHIELD

Fig.2-ItemC) (

The Front S

entrapment, and

REWINDER

Fig.2-ItemD) (

The Rewinder

In-Line via the

FEED GATE

(Fig.2-ItemE)

he Feed Gate controls the images entering tT

will activate ac

edisplay, and giv

FEED BELTS

Fig.2-ItemF) (

The Feed Belts move the

t ip. hen into the n

TABLE SIDE GUIDES

(Fig.2-Ite

The Table Side Guides are adjustable to ensure a

feeding.

BURST ROLLER GAP ADJUSTMENT KNOB

(Fig.3-ItemH)

The Burst Roller Gap Knob raises and lowers the Burst

oller. Depending on the mediaR

operator can raise or lower the Burst Roller

ing of the images. Burst or Snapp

DECURLING ADJUSTMENT KNOB

(Fig.3-ItemI)

The Decurling Adjustment Knob is used in conjunction

with the film shaft brake to increase or decrease the a

of curl desired by the oper

n the Main Rolocated betwee

FEED INDICATOR LED

(Fig.4-ItemJ)

The Feed Indicator LED will indica

can be placed on the F

LED is illumplaced until the

FEED GATE STOPS

(Fig.4-ItemK)