GBC 620os Operation Manual

© 2007 General Binding Corporation Page 20

OUTPUT TROUBLESHOOTING

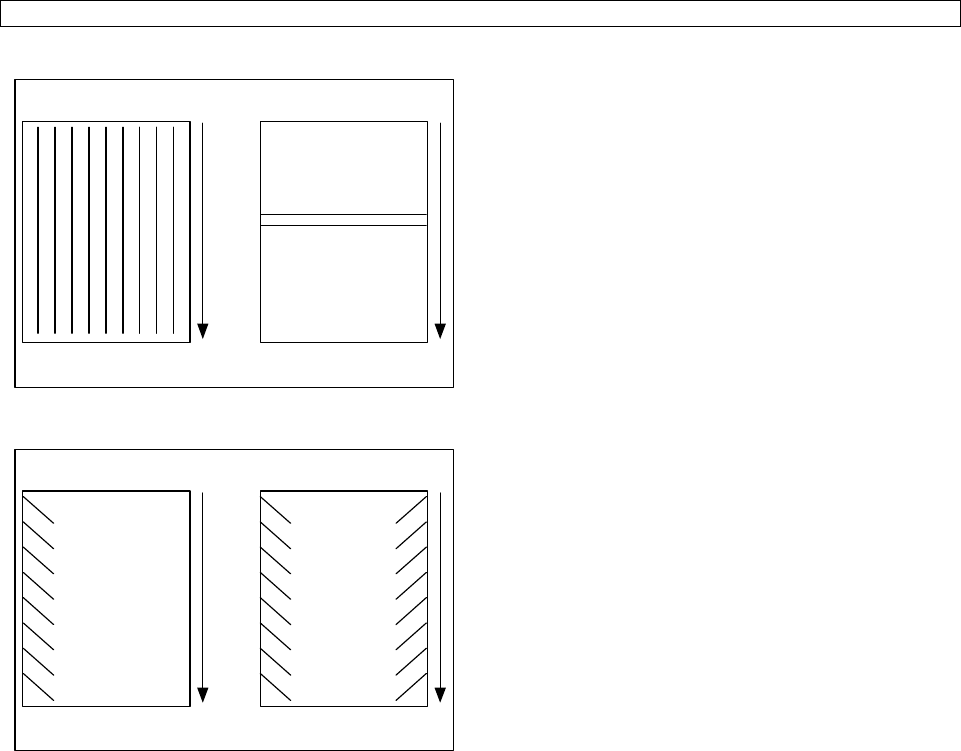

- A - - B -

Figure 1 A & B

- A - - B -

Figure 2 A & B

1. Straight waves in output (Fig. 1A).

• Check operational settings for materials being

used.

• Check for moisture in the media.

2. Indent waves in output after pull rollers (Fig. 1B).

• Bursting PSI too high.

• Output was handled prior to cooling.

• Use cooling feature if not on.

• Machine was stopped on print.

3. Angled waves in the output (Fig. 2A&2B).

• Main air Supply setting

• Check main Roller Pressure.

• Check pull roller pressure.

• Check for Paper Tension.

• Check Nip for accuracy.

4. Curled Output. (Not Shown)

• Too much Brake Tension

• Increase or decrease the amount of Decurling

Bar being used.

• Images not being fed with the grain oriented

correctly