GBC 620os Operation Manual

© 2007 General Binding Corporation Page 15

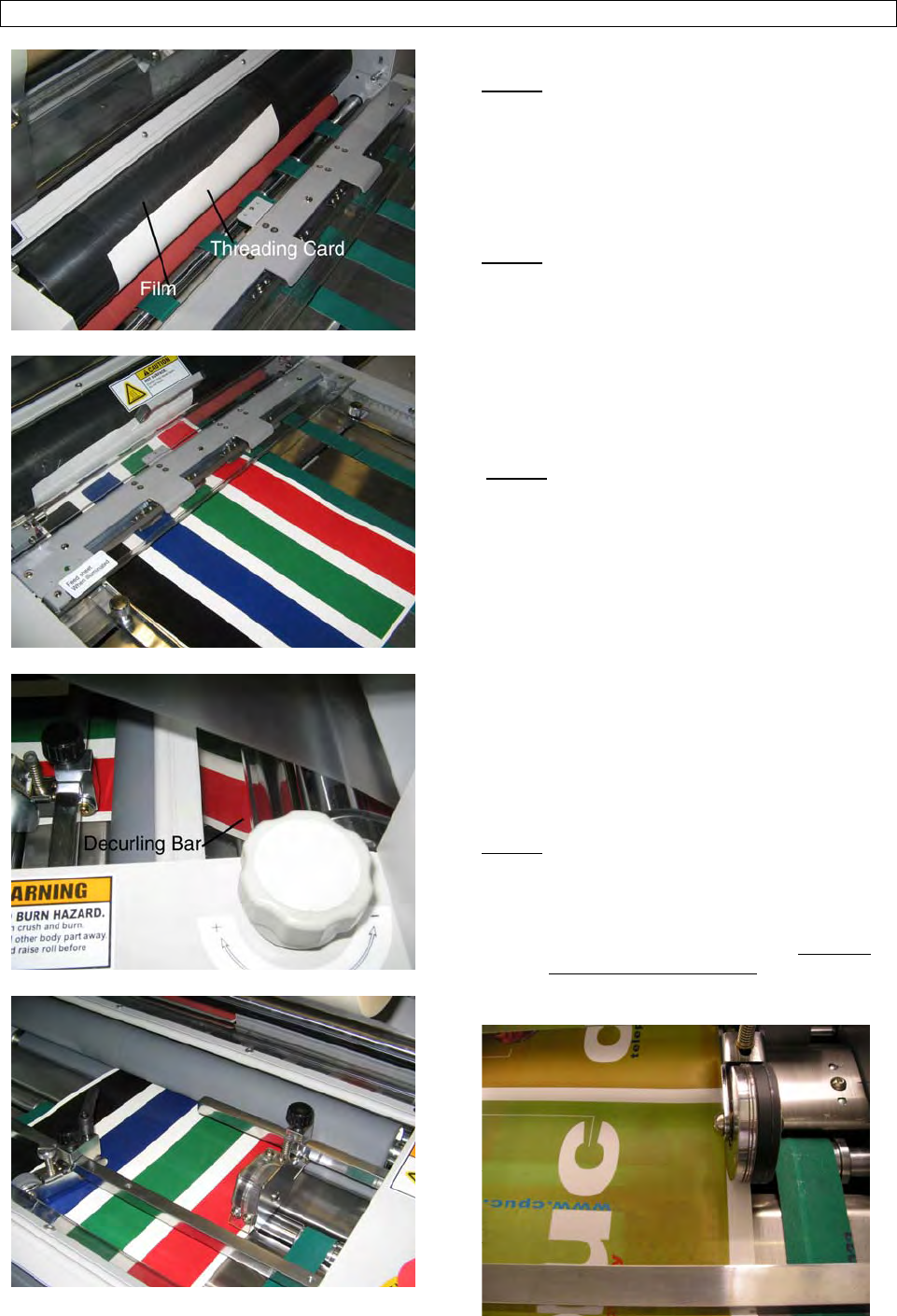

LOADING FILM & THREADING FILM

Figure5

Figure 6

Figure 7

STEP 5:

• Attach the end of the Threading Card to the

activated film. The Top Main Roller must be

hot to activate the adhesive to ensure that the

Threading Card sticks. (Figure 5).

• Replace the Safety Shield and lock in the Safety

Shield’s Safety Interlocks.

STEP 6:

• While pressing “LOADING”, push another sheet

into the nip area under the sheet you just tacked

to the film. (Figure 6).

• Continue holding down “LOADING” until the

first sheet enters the Burst Rollers while feeding

additional sheets.

• Once the first sheet exits the Burst Rollers,

release “LOADING”.

STEP 7:

• Verify that the “Threading Card” and images are

traveling over the Decurling Bar. (Figure 7).

Monitor the amount of curl of the finished

laminated images. Adjust the Decurling Bar

Knob to increase or decrease the amount of curl

desired.

• Press “START”

• When the green LED is illuminated, place

another image onto the Feed Belts and guide it

into the Feed Gate. The Feed Gate will

automatically activate according to sheet size and

open, allowing the image to be entered into the

nip.

• When the green LED is illuminated, place

another image onto the Feed Belts and guide it

into the Feed Gate.

STEP 8:

• Set the In-Line Perforator Wheel on the very

outer edge of the image but still making contact

with the film. Make any adjustments needed to

ensure the Perforator Wheel is penetrating the

film, leaving small holes in the film. Verify that

the gray wheel is off the image. (Figure 8&8A).

Figure 8A