Maintenance

313872N 29

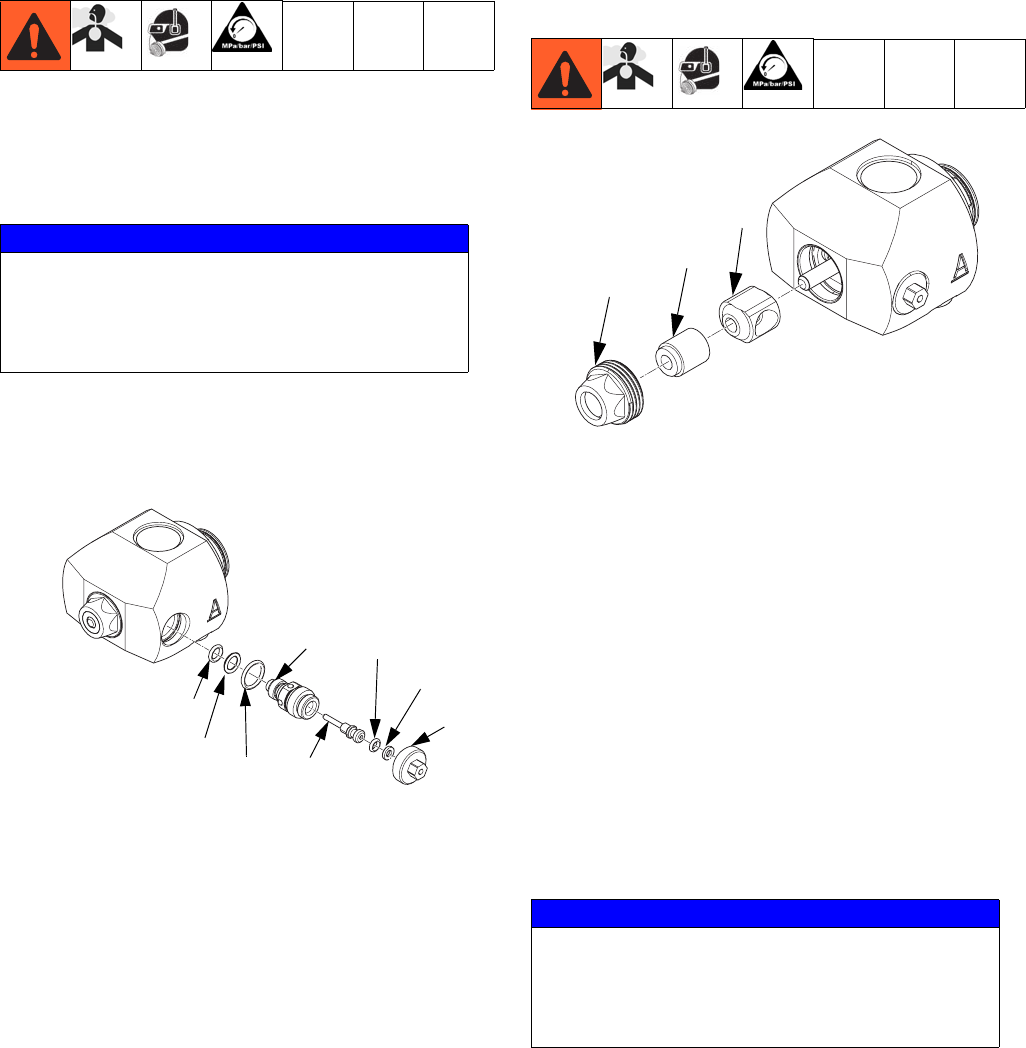

Clean Orifice

1. Follow Pressure Relief Procedure on page 22.

2. Use 5/16 in. nut driver (supplied) to remove

orifices (C). See F

IG. 4 on page 16.

NOTE: The cap is held in place with reverse threads.

3. Remove cap (25f) from orifice (25g).

4. Remove needle (25h) from orifice. Thoroughly

inspect all o-rings and replace if necessary.

5. If necessary, use drill bit that is the same size as the

orifice to drill out the orifice. Orifice size is marked

on the orifice.

6. Use Fusion grease to liberally lubricate all o-rings.

7. Reassemble in reverse order. Torque orifice body

into orifice cap to 60-70 in-lb (6.78-7.91 N•m).

Torque orifices into fluid housing to 20-30 in-lb

(2.26-3.39 N•m).

NOTE: Back-up ring (25e) is placed behind the o-ring

(25d) on the needle.

Replace Mix Chamber and Front

Seal

1. Follow Pressure Relief Procedure on page 22.

2. Use 5/16 in. nut driver (supplied) to remove

orifices (25, 26, 27).

3. Use a 3/4 in. wrench to remove front pour tip (19).

4. Connect air quick coupler (AC).

5. Press and release trigger to push out the mix

chamber (17) and front seal (18) and discard.

6. Disconnect air quick coupler (AC).

7. Install new mix chamber and front seal.

8. Replace front pour tip and torque to 60-70 in-lb

(6.78-7.91 N•m).

9. Replace orifices. Torque to 20-30 in-lb

(2.26-3.39 N•m).

NOTICE

To prevent cross-contamination of the orifices do

not interchange A component and B component

parts. The A component orifice is marked with an

A.

25g

25d

25e

25f

25a

25b

25c

25h

ti19573a

NOTICE

To prevent cross-contamination of the orifices do

not interchange A component and B component

parts. The A component orifice is marked with an

A.

ti19574a

17

18

19