15 - 8

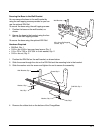

5. Slide the base onto the DIN Rail using the slot on the bottom of the base.

Channel Bracket Installation (Pre-existing Hardware Installations)

When choosing a location and installing the optional channel bracket:

• Do not exceed 150 lbs. maximum load on the channel bracket.

• Leave a minimum of 16 in. (40.64 cm) of horizontal space between the hardware used to attach the

channel bracket to the wall.

• An electrical outlet must be easily accessible.

• The mounting location should be dry, stable, easily accessible, and well lighted.

Tools Required

•Drill

• 7/8 in. Drill Bit (for hollow wall installations) or 1/4 in. Drill Bit (for wood stud installations)

• #2 Phillips Screw Driver

• Medium Flat Head Screw Driver

• 9/16 in.Socket Wrench

Hardware Required

• 3/8 in.-16 spring nut, for 13/16 in. deep strut, Qty. 4 per wall bracket

• 3/8 in. flat washer, Qty. 4 per wall bracket

• 3/8 in.-16 x 1.00 in., cap screw, grade 5, Qty. 4 per wall bracket

•

Hollow Wall Installations:

3/8 in. x 4 in. round head toggle bolt, 2-5/8 in. usable length, Qty. 4

3/8 in. flat washer, Qty. 4

•

Wood Stud Installations:

3/8 in. x 2 1/2 in. length hex head lag screw, Qty. 4

3/8 in. fat washer, Qty. 4

Wall Bracket

Wall Bracket

DIN Rail