7

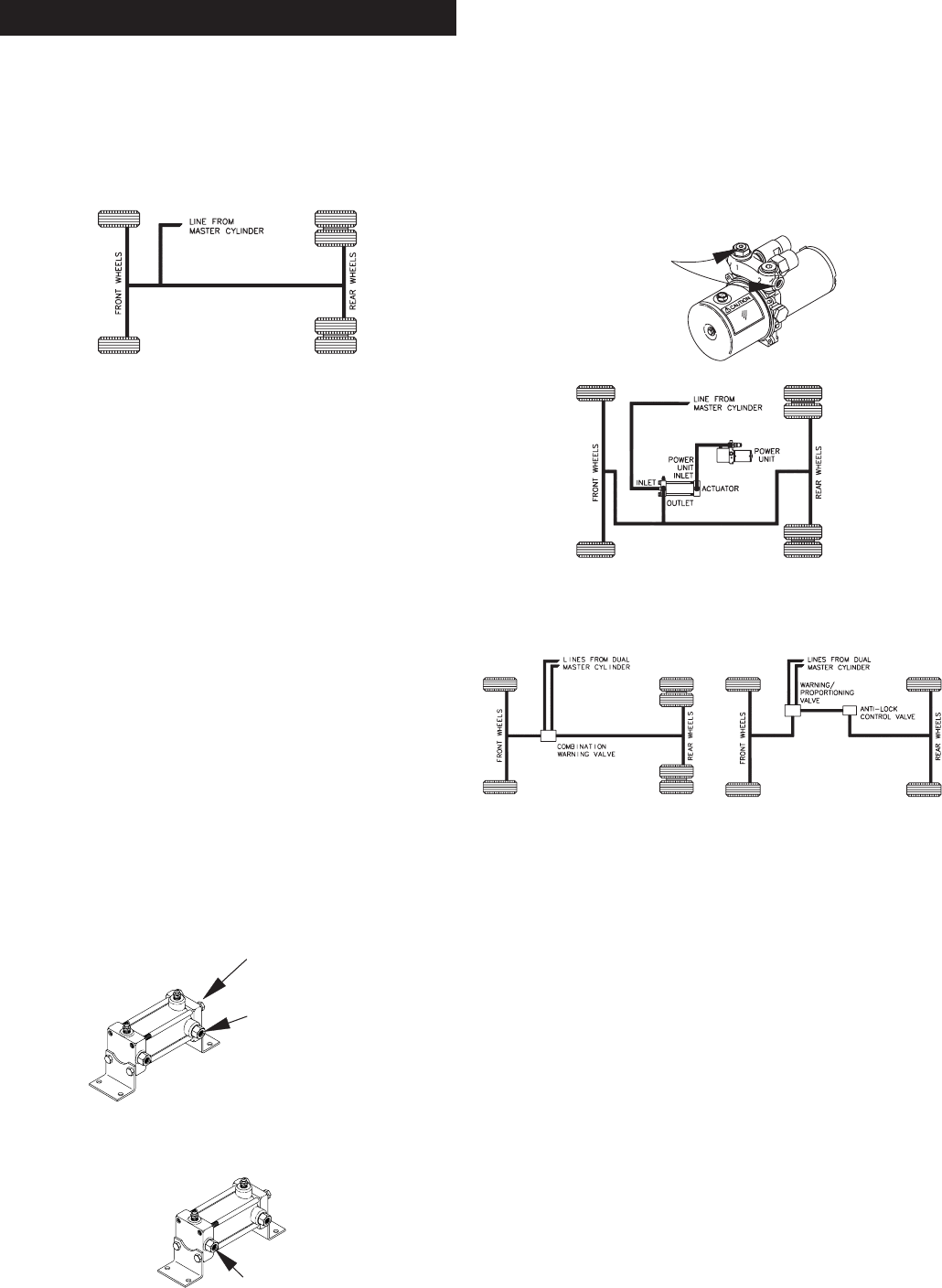

Determine the type of brake system on your vehicle, refer

to pages3&4.Allbrake systems in use today require the

MICO 691 Actuator(s) be installed after the anti-lock brake

valve and combination warning valve if so equipped.

Contact MICO, Incorporated if you have questions.

Single 691 Brake Lock System

1. Disconnect the existing brake line necessary to install

the single actuator. Reduce fluid loss by plugging the

ports. Do not loosen or remove hydraulic lines that are

not effected by the installation of the single actuator.

2. Determine the length and shape of new or modified

brake lines needed to install the actuator. The installer

must be qualified to modify existing brake tubing, or

new factory double flared SAE approved brake line

must be used. When adding or replacing brake lines,

do not use smaller diameter than existing lines. The

MICO 691 Actuator is supplied with brass adapters

designed to mate with 1/4" inverted flare tube nuts.

Contact MICO, Incorporated or a local brake fitting

supplier to obtain proper fittings to install different size

lines. All new connections or modifications between

flexing vehicle sections, such as vehicle body and

frame, must be made to absorb shock and vibration.

Common methods used to absorb this shock are

coiling the brake tubing or using a short length of

purchased brake hose. Follow procedures outlined by

the vehicle manufacturer or SAE specifications.

3. Connect the upstream line coming from the vehicle

master cylinder to the fluid inlet port on the end of the

single actuator. Connect the downstream line going to

either the front or rear brakes from the side outlet port

on the same end of the single actuator. See Figure 16.

4. Determine the shape and length of a new piece of

tubing to connect the power unit and single actuator.

See Figure 17.

5. Connect one end of the new tubing to the single

actuator.

6. Connect the other end of the new tubing to the power

unit. This connection can be made to either the side

or top port. Remove the plastic shipping plug from the

top port. To install line in the side port use 3/16" hex

key wrench to move the steel plug from side port to

top port. Install the remaining brass adapter from the

fitting package in the selected port prior to connecting

the line. See Figure 18.

Dual 691 Brake Lock System

1. Disconnect the existing rear brake lines necessary to

install the dual actuator. Reduce fluid loss by plugging

the ports. Note which master cylinder port supplies

fluid to the front brakes and rear brakes. Do not

reverse the front and rear fluid paths during the

installation of new brake lines.

2. Determine the length and shape of new or modified

brake lines needed to install the dual actuator. The

installer must be qualified to modify existing brake

tubing, or new factory double flared SAE approved

brake line must be used. When adding or replacing

brake lines, do not use smaller diameter than existing

lines. The MICO 691 Actuator is supplied with brass

adapters designed to mate with 1/4" inverted flare

tube nuts. Contact MICO, Incorporated or a local

brake fitting supplier to obtain proper fittings to install

different size lines. All new connections or modifica-

tions between flexing vehicle sections, such as vehicle

body and frame, must be made to absorb shock and

Single Brake System

F

rom

Master Cylinder

(port not shown)

To Brakes

From

P

o

w

e

r

U

ni

t

FIGURE 16

FIGURE 17

PLUMBING

Single Brake System with 691 System

Plug One of

These Ports

FIGURE 18

Dual Brake Systems