16

Utility Software

Touch Panel Software

Utility Software

Touch Panel Software

■ Face Plate Auto-Builder for NS

Simply specify the CSV tag file created using the CX-Process Tool to automatically create a project constructed with a Face Plate for Loop-control

CPU Units for use with OMRON's NS-series Programmable Terminals.

Function Overview

• Create windows for monitoring and tuning PID and other function blocks for up to 100 loops (NS System version 4 or higher).

• NS project files for monitoring multiple Loop-control CPU Units from a single NS-series PT can be generated from CX-Process projects for up to

32 multiple nodes.

• When a Segment Program 2 or 3 function block is used for program operation, the Detailed Setting Windows (Time Interval vs. Output Value

Setting Window, Wait Interval Setting Window) used for the parameter settings are also automatically generated.

• NS-Runtime is supported.

Basic Specifications

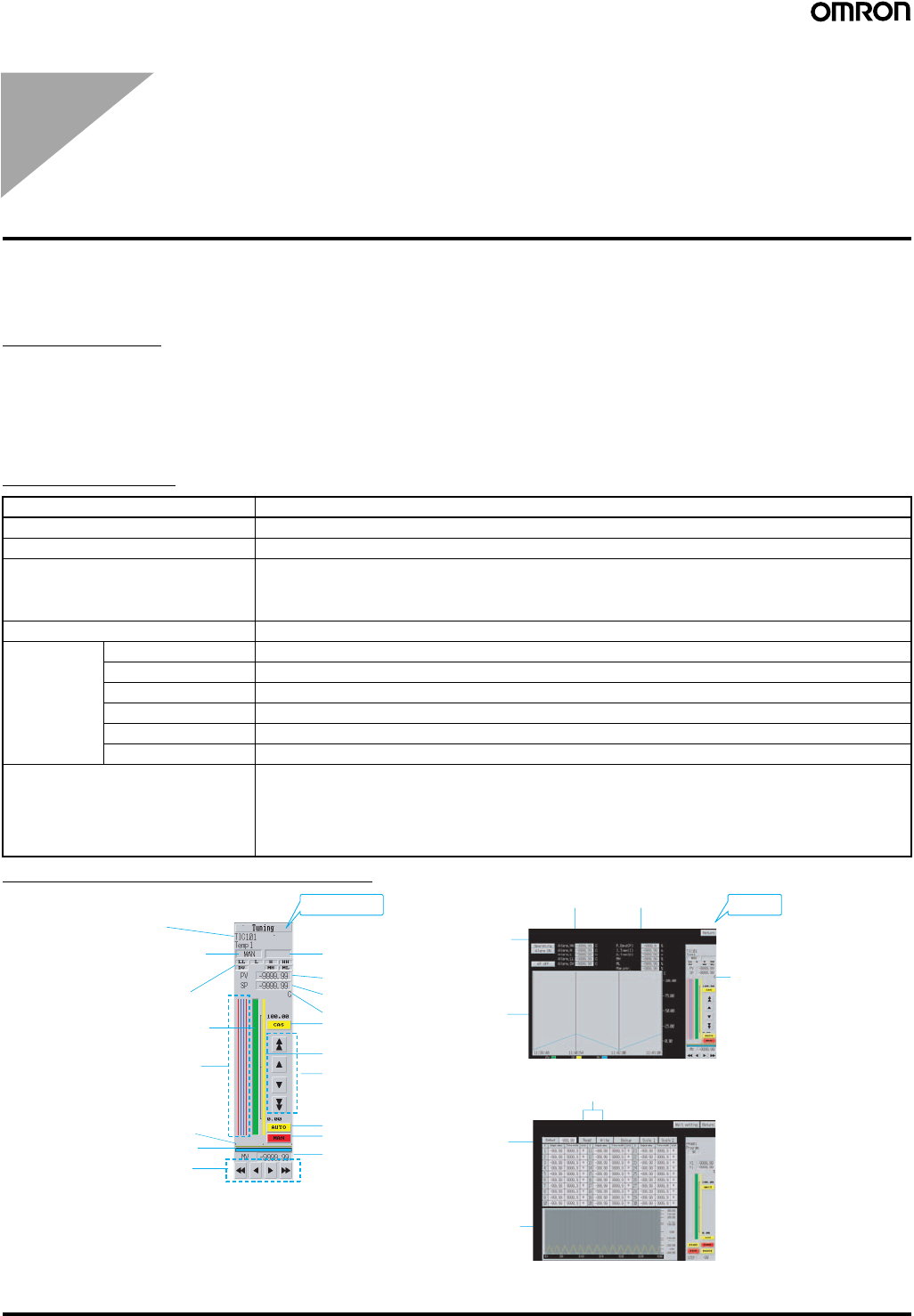

Example of Automatically Created Windows

Item Specifications

Name Face Plate Auto-Builder for NS

Model number WS02-NSFC1-EV3

Applicable PLC products CJ-series Loop-control CPU Units

CS-series Loop Control Boards (unit version 1.0 or later)

CS-series Loop Control Units (unit version 2.0 or later)

CS1D Process-control CPU Units

Applicable PTs NS-series NS12, NS10, and NS8 (PT version 2.0 or later), CX-Designer

System

requirements

Computer IBM PC/AT or compatible

CPU Celeron 400 MHz or better recommended

OS Microsoft Windows 98SE, NT4.0 (Service Pack 6a), 2000 (Service Pack 3 or later), or XP

Memory Recommended: 32 Mbytes min.

Hard disk storage Recommended: 200 Mbytes free space min.

Monitor Minimum: 640

× 480 dots

Basic functions Number of generated loops:100 max., control windows and tuning windows

Applicable face plates: 2-position ON/OFF, 3-position ON/OFF, Basic PID, Advanced PID, Indication and

Operation, Indicator, Segment Program 2 (includes the parameter setting windows),

Segment Program 3 (includes the parameter setting windows)

Number of loops in control windows: 6 loops per window for NS12, 4 loops per window for NS10/NS8

Realtime trend in tuning window: 1-second cycle

Tuning Window

Basic PID Block Screen

Segment program details setting window

MV numerical value

display/input

MAN button/display

AUTO button/display

Time interval,

output value,

and unit for

each step

Setting confirmation

graph (horizontal axis

shows steps)

Up/Down buttons to change SP

SP bar display

CAS button/display

Unit display

SP numerical value display/input

PV numerical value display

Status display 2

(PV error, MV error)

Status display 1

(AUTO, MAN, CAS)

Tag No.

Tag comment

Alarm status

indicators

PV bar display

Alarm set

value display

MV indicator

MV bar display

Up/Down

buttons to change

MV

To Tuning Window

To Control

Window

Write/read setting data

Realtime trend

display

Switch status

Alarm setting Parameter settings

Function

Block Face

Plate