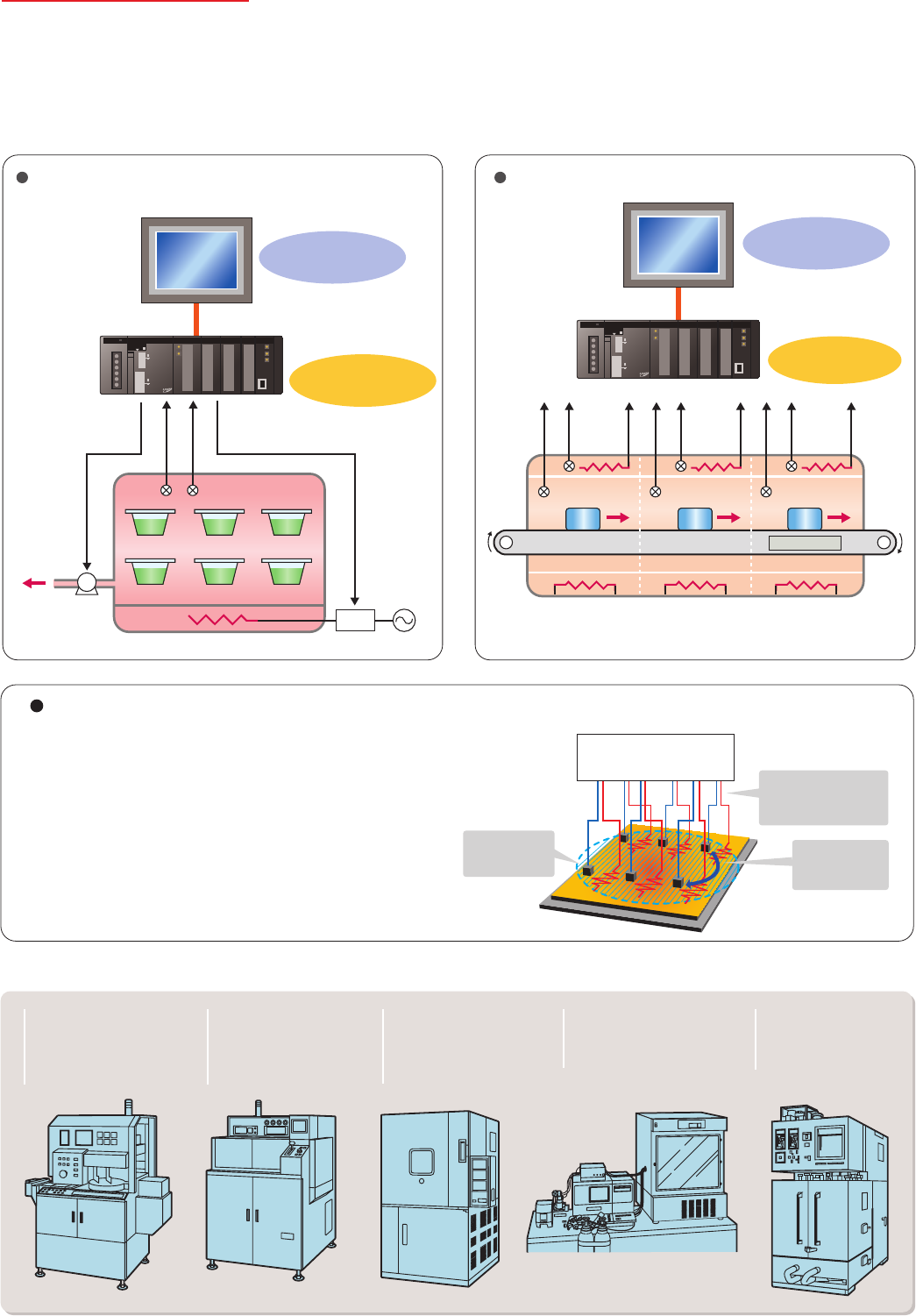

Sterilization and Disinfection of

Pharmaceuticals, Food and Beverages

Loop-control CPU Unit

Loop-control CPU Unit

N2 atmosphere

Solder

Workpiece

Conveyor

NS-series PT

NS-series PT

Heater

Temperature

sensor

SCR

Temperature

Thyristor

Pressure

Control outputsControl outputs

Logging Trend Data

(monitoring and operation

windows)

Monitoring and operation

windows or heaters and

temperature sensors

Program pattern

control

Cascade control of

tunnel furnace

Industrial Furnace

6

Applications

Providing Solutions to Other Problems

The Loop-control CPU Unit Provides You with Solutions for the Complex and Advanced

Functions Demanded by Control Devices in an Increasingly Diverse Range of Equipment.

CPU: CJ1G-CPU45P-GTC

Electrical parts equipment

requiring high-speed

temperature control for

higher precision and

improved tact time.

Diffusion furnaces that

perform cascade control

of heater temperatures

and internal chamber

temperatures.

Food machines, semi-

conductor devices and

other machines requiring

multipoint temperature

control.

Fermentation equipment

requiring temperature,

pressure, flowrate, and pH

control.

Testing devices that

frequently change

setting conditions and

program settings.

Average

temperature

controlled.

Temperature

differences

controlled.

Interference at other

control output points

suppressed.

Gradient temperature

control

Example: Planar Temperature Control of Multi-stage Furnaces,

Wafer and Glass Surface Temperatures, and Other Applications.

Gradient Temperature Control for Planar

Temperature Control Across Multiple Points

Note: CJ1G-CPU45P-GTC only.

Gradient temperature control equalizes the temperatures at

multiple points, providing high-quality heat processing,

reducing energy loss until temperatures stabilize, and saving

labor in adjustments due to interference between heaters.

For details, refer to the SYSMAC CS/CJ Series Controllers for Gradient

Temperature Control Catalog (R141).