16

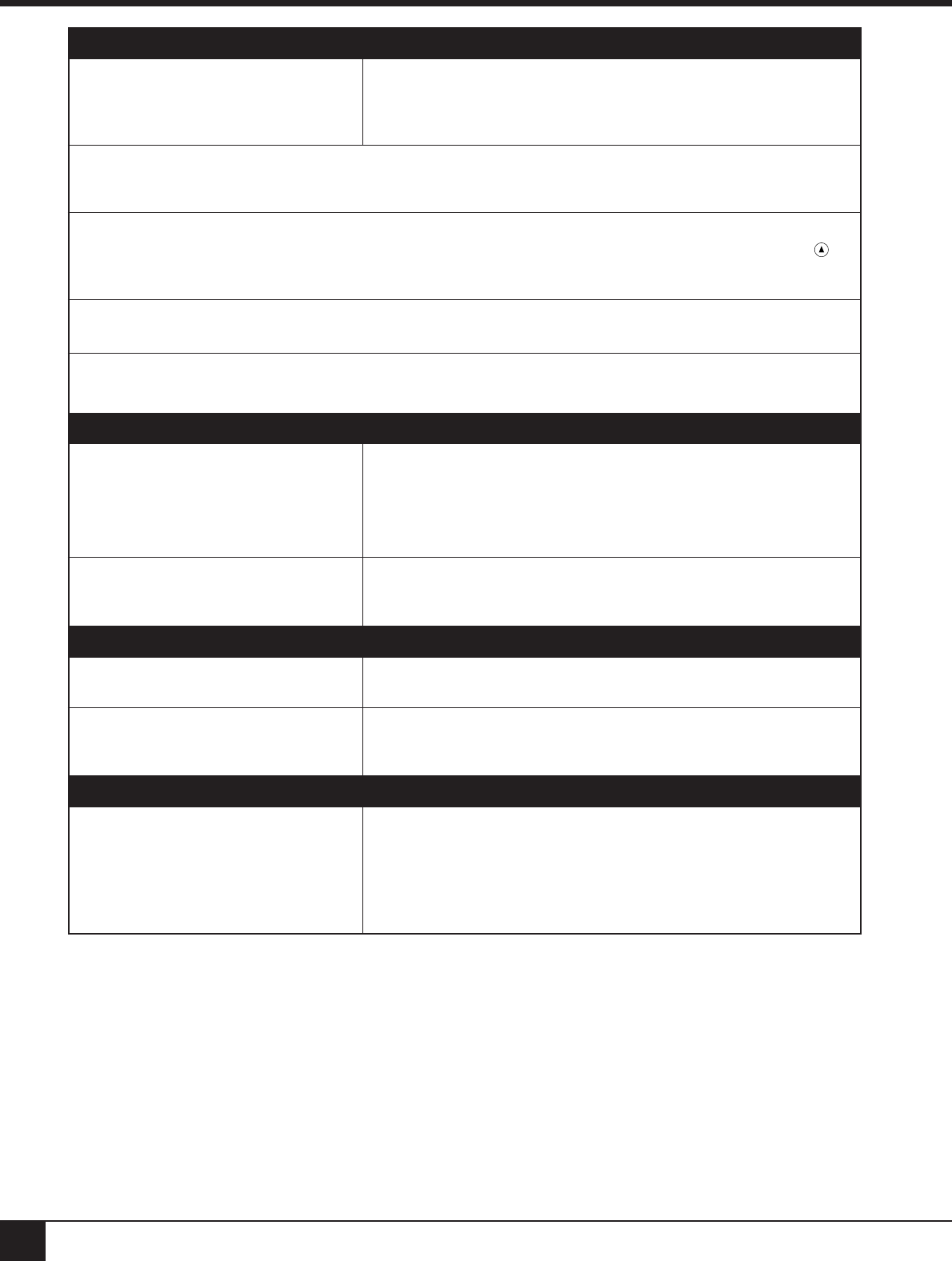

10 What to Do If...

The material slips away from the pinch rollers during operation

Are the sheet loading levers on both the

left and right sides raised?

If a sheet loading lever has not been raised, then the material has not been secured

in place. Make sure that the pinch rollers on the left and right sides are within the

boundaries of the material, and raise the sheet loading levers. (See “5-5 Loading/

Removing the Material” .)

Make sure the material is parallel with the grit roller.

If the front edge of the material rests at an angle, cut off the odd-shaped part to make it straight. Then align it so that it is parallel with

the grit roller.

If the material is to be advanced over a long distance, moving the movable pinch roller inward slightly can help prevent the material

from becoming dislodged. Also, after loading the material, it is recommended that you carry out an alignment test by using the

key to advance the material by the amount that will be used for printing or cutting. Make sure that the material travels correctly

through the machine.

If roll material is used, print or cut only after first pulling out the amount of material that is to be used. The PNC-5000 is not designed

to pull material off rolls.

Make sure that the left and right edges of the material do not touch the inner surfaces of the PNC-5000 during operation. Such contact

may damage the material, and could also make it impossible to advance the material–thus causing it to slip.

The POWER/ERROR LED is blinking

Are the application software settings

correct?

Check the following items:

• Output device specifications (select a device name that matches the instruc-

tion system. If the wrong device is selected an incorrect instruction may be

output, resulting in an error).

• Communication parameters • Other settings

Check the software user’s manual and set it up correctly.

If connected via the serial port, do the

communication parameters for the PNC-

5000 match those of the computer?

Set the DIP switches correctly (see “5-1 DIP Switch Settings” .)

PAUSE LED and POWER/ERROR LED blink simultaneously

Is the ribbon cartridge installed correctly? Install the ribbon cartridge correctly on the printing carriage (see “5-4 Installing a

Ribbon Cartridge”).

Has the ink ribbon been used up? If there is no more ink ribbon left for printing, replace the ribbon cartridge with a

new one (see “5-4 Installing a Ribbon Cartridge”).

SETUP LED and POWER/ERROR LED blink simultaneously

Is the material loaded correctly?

Does the front of the material stick out to

the front surface of the PNC-5000?

Is the length of the loaded material too

short?

Load the material correctly (see “5-5 Loading/Removing the Material”).