7. SUPPLY SPECIFICATIONS ENGLISH VERSION EO1-33047

7.1 Media

E7- 2

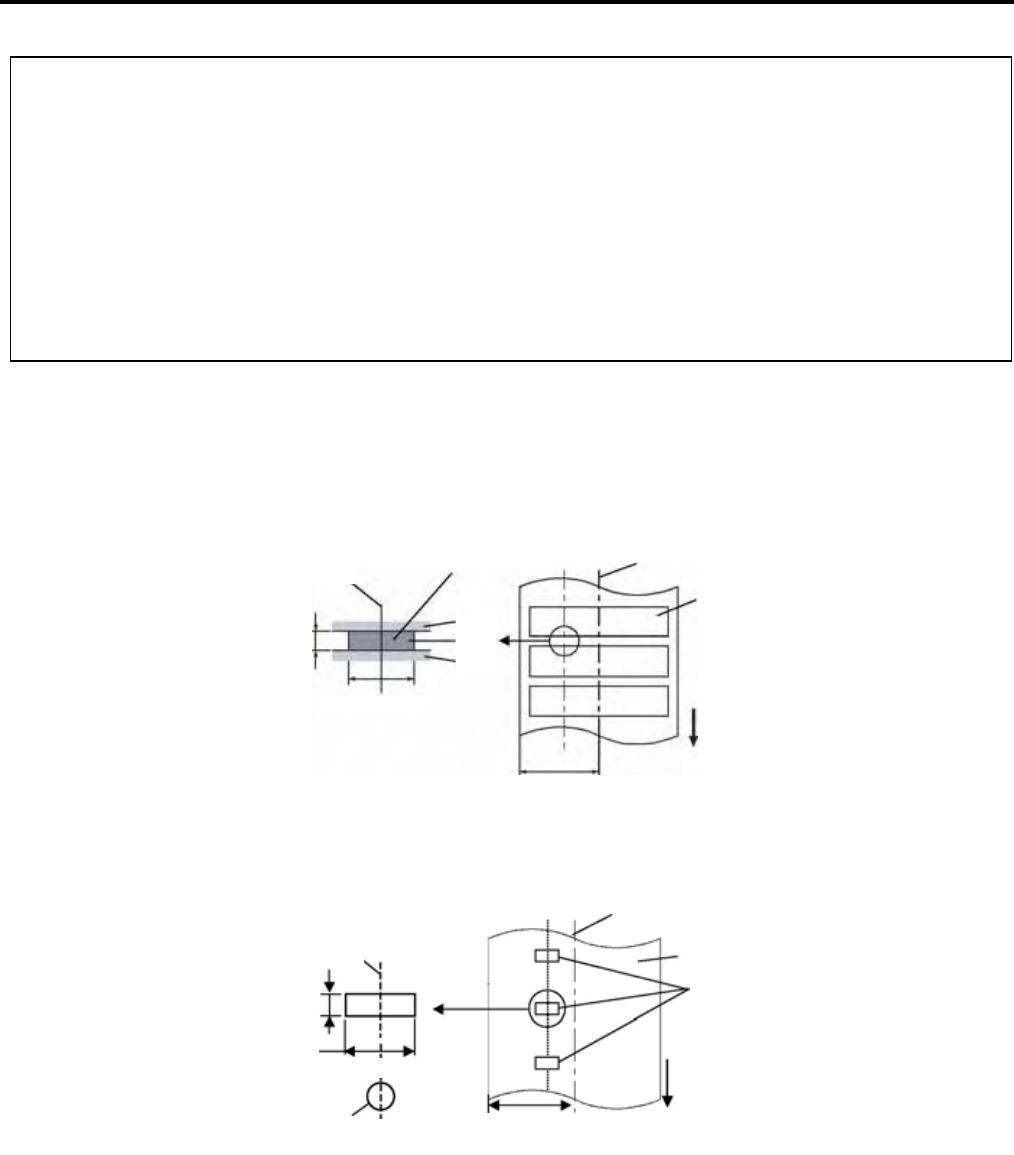

7.1.2 Detection Area of the Transmissive Sensor

The Transmissive Sensor is movable from the centre to the left edge of media.

The Transmissive Sensor detects a gap between labels, as illustrated below.

<Label>

<Tag paper with square holes>

N

OTES:

1. To ensure print quality and print head life use only TOSHIBA TEC specified media.

2. The ratio of a label length to a gap length must be a minimum of 3 to 1 (3:1).

3. Backing paper must be wider than a label; the distance between the edge of the backing paper and that of a label

should be at least 1.5 mm.

4. Use of the tag paper of 25 mm to 50 mm in width, and 171

µ

m to 263

µ

m in thickness may shorten the platen life.

5. When using a label stock in cut mode, be sure to cut the gaps. Cutting labels will cause the glue to stick to the

cutter, which may affect the cutter performance and shorten the cutter life.

6. To tear off printed media in batch issue easier, set the Auto Forward Wait function (FORWARD WAIT

parameter) to ON in the system mode. When this function is effective, the printer stops feeding the printed media

past the strip shaft. In case of a label stock, however, if a next label is issued without tearing off the printed label,

the label may peel while it is fed backward, causing a printer failure.

Sensor position

A

rea to be detected.

Centre of media

Print side

Min. 12 mm

Label

Gap

Label

Min. 2.0 mm

Sensor is movable

within this range.

Media feed direction

Sensor position

Centre of media

Min. 12 mm

Media feed direction

Min. 2.0 mm

Sensor is movable

within this range.

Rectangular holes

Print side

Round hole

Min. Ø 2.5mm