Measurement Considerations Using the Power Sensor

3-14 MA24106A UG

Error States

This section details some of the error messages that may appear on the application screen. In most cases, the

error condition can be easily corrected. The status LED will light yellow when an error state occurs. If not, note

the error message and contact an Anritsu Service Center.

3-9 Measurement Considerations

Time Varying Signals

Case 1: Modulated signals with pulse or pattern repetition times ≤ 1ms (PRF ≥ 1KHz)

If you obtain a steady power reading of a modulated signal (no significant fluctuations of the displayed power)

with no averaging, then it is likely that the pulse or pattern repetition rate is greater than 1 KHz. In this case,

most of the averaging of the envelope power is performed in the front end of the sensor (before being digitized).

When this is the case, the MA24106A will provide an accurate indication of the average power with no special

considerations.

Case 2: Modulated signals with pulse or pattern repetition times between 1 ms and 50 ms

(100Hz <PRF <1KHz)

In this case, the signal is varying too slowly to be averaged in the front end of the sensor, so averaging must be

performed after digitalization by increasing the averaging number in the power meter application (or

calculating the average of several measurements if controlling the sensor over the bus). A large amount of

averaging must be used for some pulse/pattern repetition frequencies to get a steady reading. If Low Aperture

Time (LAT) mode is selected, the maximum recommended pulse repetition time is about 10 ms. If High

Aperture Time (HAT) mode is selected, signals with pulse repetition periods as long as 50 ms can usually be

measured.

Case 3: Modulated signals with pulse or pattern repetition times greater than 50 ms

In this case, it can be difficult to get an accurate average power reading even by averaging many readings. The

sample rate of the sensor and the pulse repetition rate of the signal may be close enough that they can “beat”

together resulting in low frequency modulation of the power indication. If averages are not calculated over

many of these beats, or an integer number of beats, errors can result. This is not unique to the MA24106A and

can be an issue with any power sensor/meter and any sampled data system.

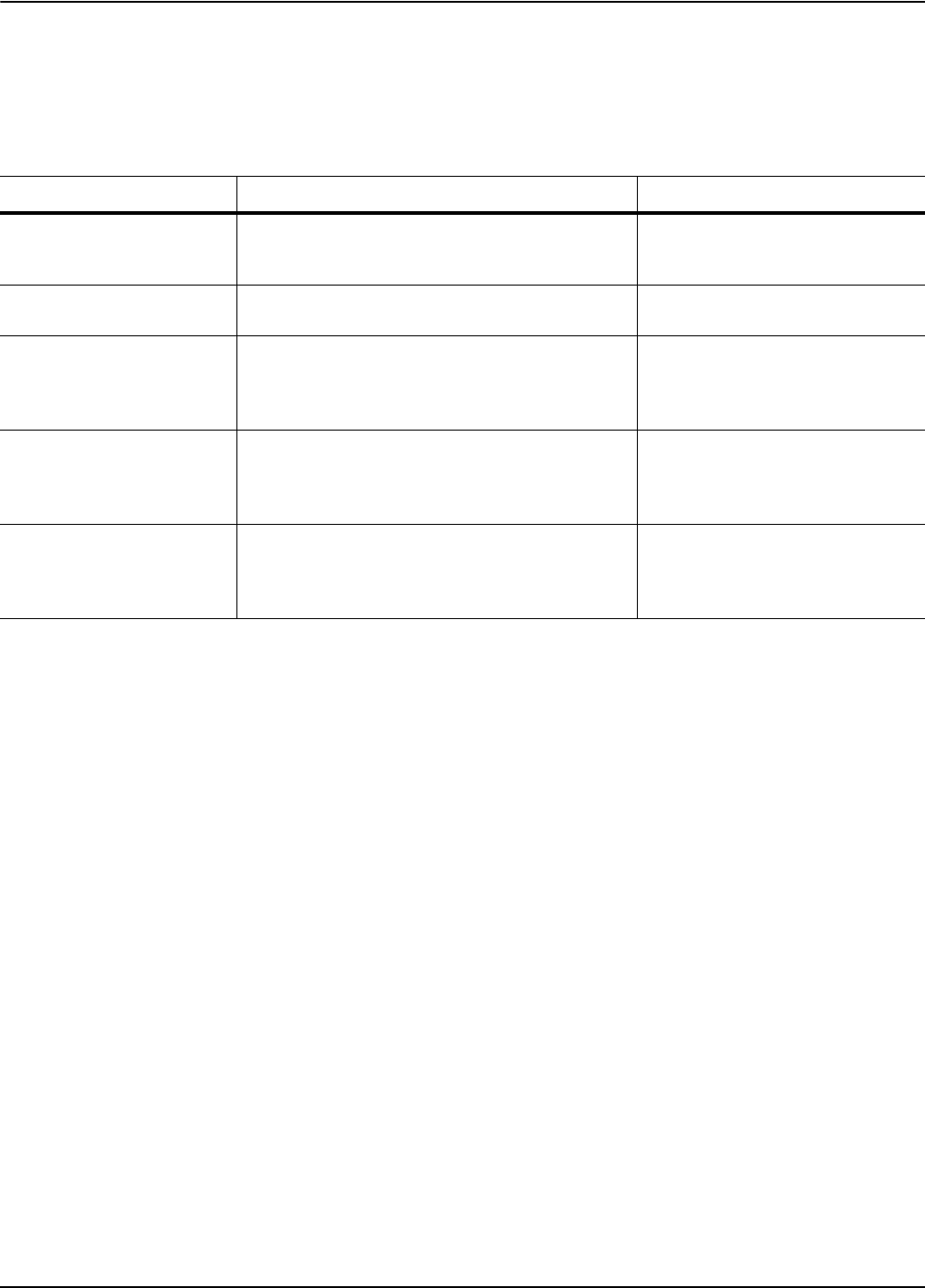

Table 3-3. Error Messages

Message Description Resolution

Zero invalid as temperature

changed by more than

10 Degrees C

The sensor’s ambient temperature has changed

by more than 10 ºC since the last zero

operation.

Perform the zero operation again.

Temperature out of

operating range

Operating range of the sensor is 0 ºC to 55 ºC. Re-examine the ambient

conditions.

Sensor zero failed This message box appears if the zero operation

is unsuccessful. The reason could be the

presence of RF power at the input of the sensor.

Turn off the RF input to the sensor

or disconnect the sensor from the

RF source and try the zero

operation again.

ZERO_ERROR This message appears on the application

screen if the zero operation is unsuccessful. The

reason could be the presence of RF power at

the input of the sensor.

Turn off the RF input to the sensor

or disconnect the sensor from the

RF source and try the zero

operation again.

ADC_TEMP_OVERRNGE This message appears on the application

screen if the sensor is being operated in

extremely high temperatures and has

overheated.

Remove the sensor from the USB

connection and allow to cool to

the operating range of the sensor:

0 ºC to 55 ºC