61

5

If the machine stops operating correctly, check the following possible problems before requesting service.

You can solve most problems by yourself. If you need additional help, the Brother Solutions Center offers the

latest FAQs and troubleshooting tips. Visit us at http://solutions.brother.com.

If the problem persists, contact the retailer who sold you this machine or the nearest authorized service center.

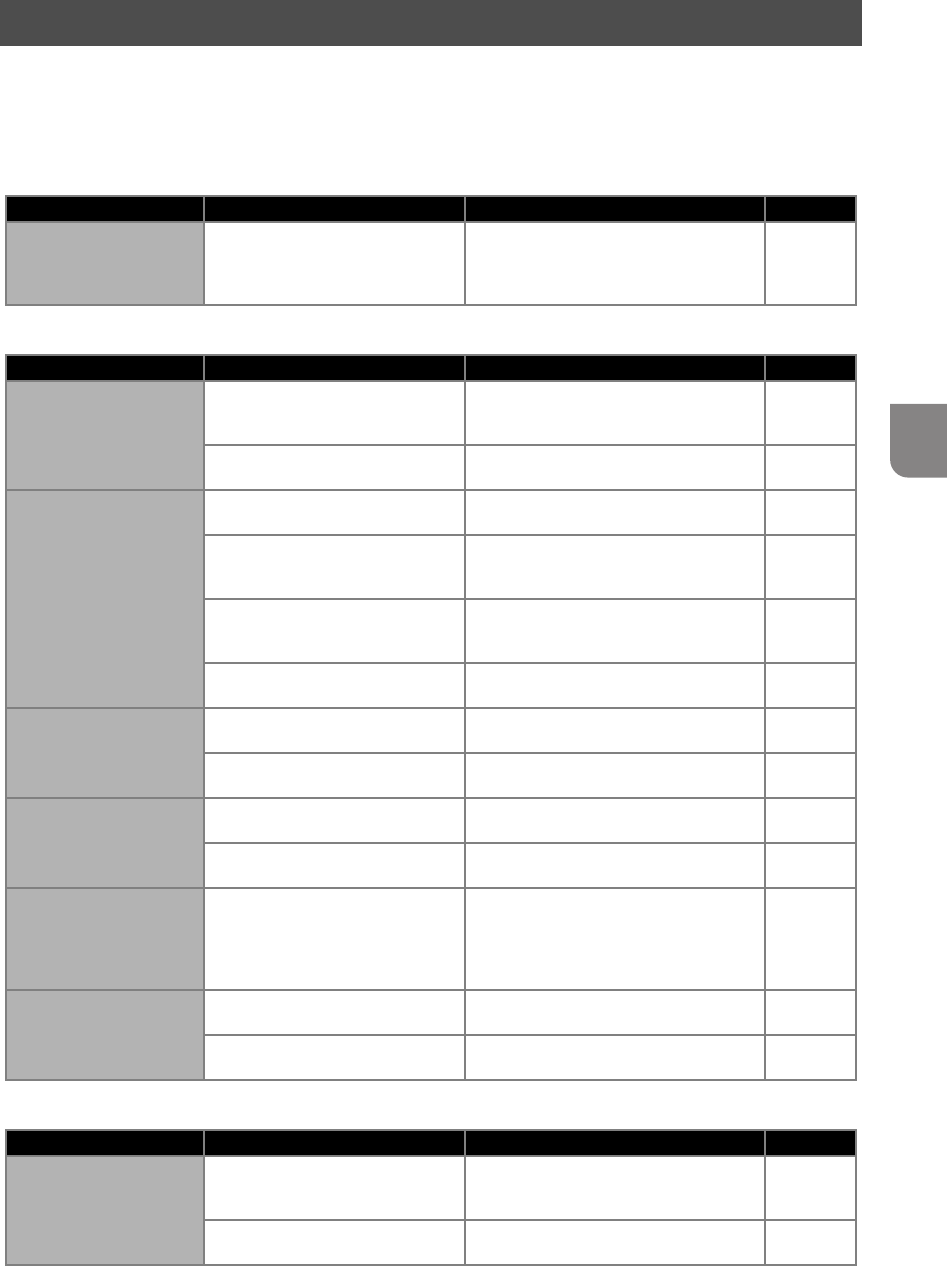

Power Supply

Mat

Paper/Fabric Jam

TROUBLESHOOTING

Symptom Possible Causes (or Results) Solutions Reference

The machine cannot be

turned on.

The AC adapter is not correctly

connected to the machine.

Check that the AC adapter is connected

to the machine and that the power cord is

connected to the AC adapter and

electrical outlet.

page 10

Symptom Possible Causes (or Results) Solutions Reference

The mat cannot be

inserted.

When the mat was inserted, it was

not placed under the feed rollers.

Insert the mat so that it is placed under

the feed rollers on the left and right sides

of the feed slot.

page 20

The mat was not loaded using the

“Feed” button.

Lightly insert the mat into the feed slot,

and then press the “Feed” button.

page 20

The mat cannot be

recognized.

The dotted marks on the part of the

mat that is inserted are dirty.

Clean the dotted marks on the mat and

their surrounding area.

page 58

The dotted marks on the part of the

mat that is inserted are hidden by

material that was attached.

Attach the material while keeping it within

the adhesive area of the mat.

page 12

The mat was inserted so that the

side with the material attached is

facing down.

Insert the mat so that the side with the

material attached is facing up.

page 20

The scanner glass is dirty.

Clean the scanner glass from the bottom

of the machine.

page 59

The mat is fed in at an

angle.

The mat was inserted into the feed

slot at an angle.

Press the “Feed” button to feed out the

mat, and then re-insert it straight in.

page 20

page 21

The corners of the mat are deformed

(bent).

Replace the mat with a new one. page 56

The material to be cut/

drawn or original to be

scanned cannot be

attached to the mat.

The material extends from the

adhesive area of the mat.

Attach the material while keeping it within

the adhesive area of the mat.

page 12

The mat’s adhesive strength has

decreased.

Replace the mat with a new one. page 56

The mat cannot be fed

out.

The material to be cut/drawn or

original to be scanned is jammed in

the feeding mechanism in the

machine.

Press the “Feed” button while the mat is

being inserted to feed it out.

If the mat does not feed out, turn off the

machine, and then carefully pull out the

mat.

page 21

When the mat is

inserted, the attached

material peels off.

The mat is not level due to the

weight of the material.

With your hands, hold the mat level when

inserting it.

page 20

The mat’s adhesive strength has

decreased.

Replace the mat with a new one. page 56

Symptom Possible Causes (or Results) Solutions Reference

The mat cannot be fed.

There is an obstruction around the

slot at the back of the machine.

Maintain space around the slot at the

back of the machine so that the mat can

be fed out.

page 9

The surface where the machine is

installed is uneven.

Place the machine on a flat, even surface. —