Loading paper

19

2

Envelopes 2

Most envelopes designed for laser printers

will be suitable for your machine. However,

some envelopes may have feed and print-

quality problems because of the way they

have been made. A suitable envelope should

have edges with straight, well-creased folds

and the leading edge should not be thicker

than two sheets of paper. The envelope

should lie flat and not be of baggy or flimsy

construction. You should buy quality

envelopes from a supplier who understands

that you will be using the envelopes in a laser

machine.

Envelopes can be fed from manual feed slot

one at a time. We recommend that you print

a test envelope to make sure the print results

are what you want before you print or

purchase a large quantity of envelopes.

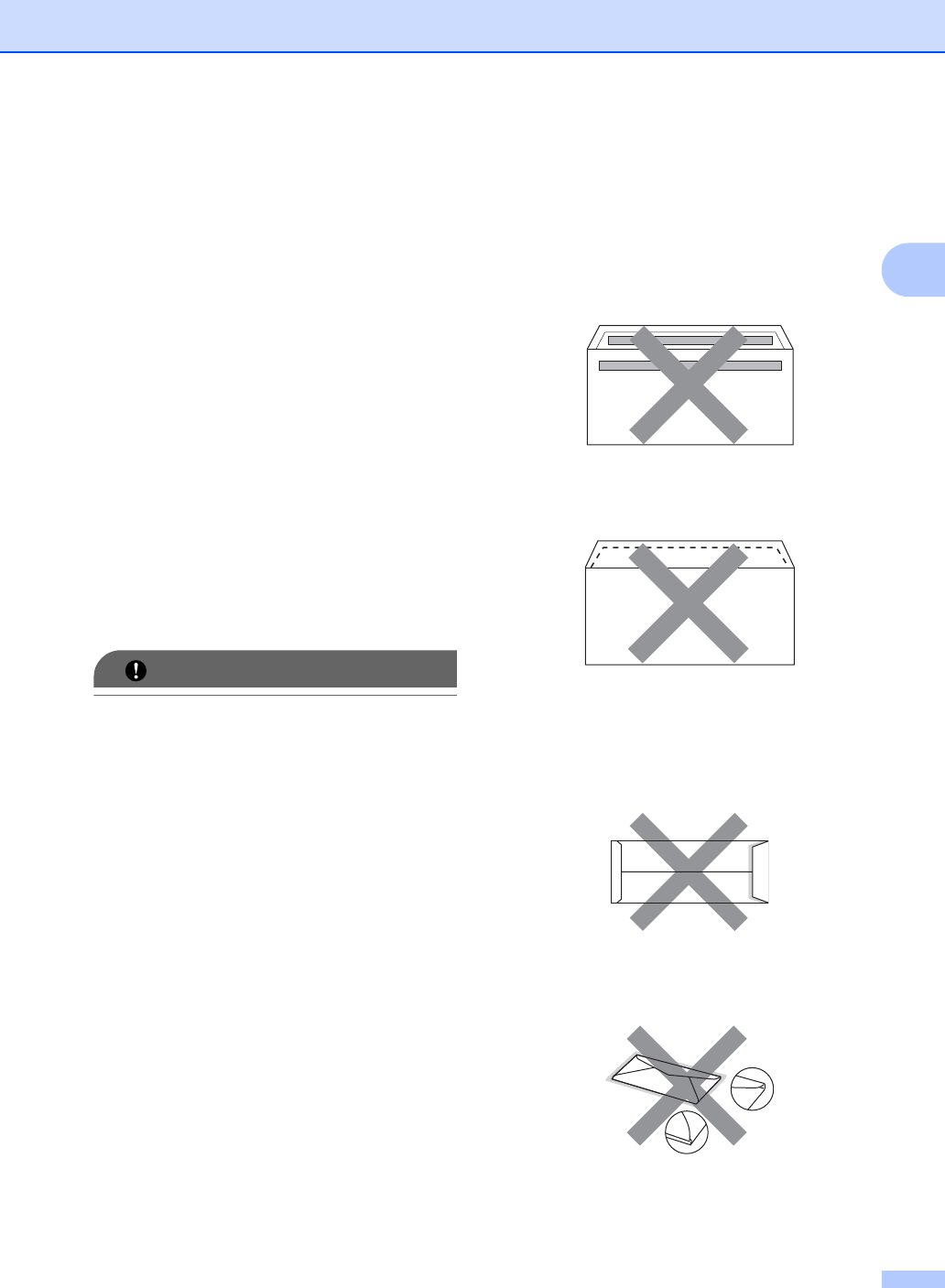

Types of envelopes to avoid 2

IMPORTANT

DO NOT use envelopes:

• that are damaged, curled, wrinkled or

an unusual shape

• that are extremely shiny or textured

• with clasps, staples, snaps or tie

strings

• with self-adhesive closures

• that are of a baggy construction

• that are not sharply creased

• that are embossed (have raised writing

on them)

• that were previously printed by a laser

machine

• that are pre-printed on the inside

• that cannot be arranged neatly when

stacked

• that are made of paper that weighs

more than the paper weight

specifications for the machine

• with edges that are not straight or

consistently square

• with windows, holes, cut-outs or

perforations

• with glue on surface as shown in figure

below

• with double flaps as shown in figure

below

• with sealing flaps that are not folded

down when purchased

• with sealing flaps as shown in figure

below

• with each side folded as shown in

figure below