Conditioned Power Center

9

2.4 Safety Interlocks

This product incorporates a safety interlock circuit that functions as a

secondary means of protection for personnel. Protective side panels and

hazard warning labels provide primary protection. However, in the event one

or more side panels are removed from the product prior to being de-

energized, the safety interlock system will de-energize the power conditioner.

The circuit consists of two safety interlock switches (one per each side access

panel) located in the center of the top side frame of the power conditioner.

The switches operate as a normally open circuit connected to the shunt trip

coil of the input circuit breaker. See Figure A. Activating either of these safety

interlock switches causes a 24 VDC signal to energize the shunt trip coil of the breaker. The 24 VDC signal is

derived from a low voltage, fused tap on the transformer secondary. The shunt trip circuit also uses stored

energy from a capacitive circuit to ensure that the shunt trip mechanism will function even in the event of a power

outage. The safety interlock switches are shown on the general circuit diagram found in subsection 10.1 of

Section 10 of this manual.

If the power conditioner shunt trips as a result of removing the side panels, hazard-

ous voltages will remain at the input voltage connection to the rear of the main cir-

cuit breaker. Entering the enclosure under these conditions is classified as a Type

4 task under SEMI S2-0200 guidelines. This can be changed to a Type 1 task by disconnecting power at

the source before entering the enclosure.

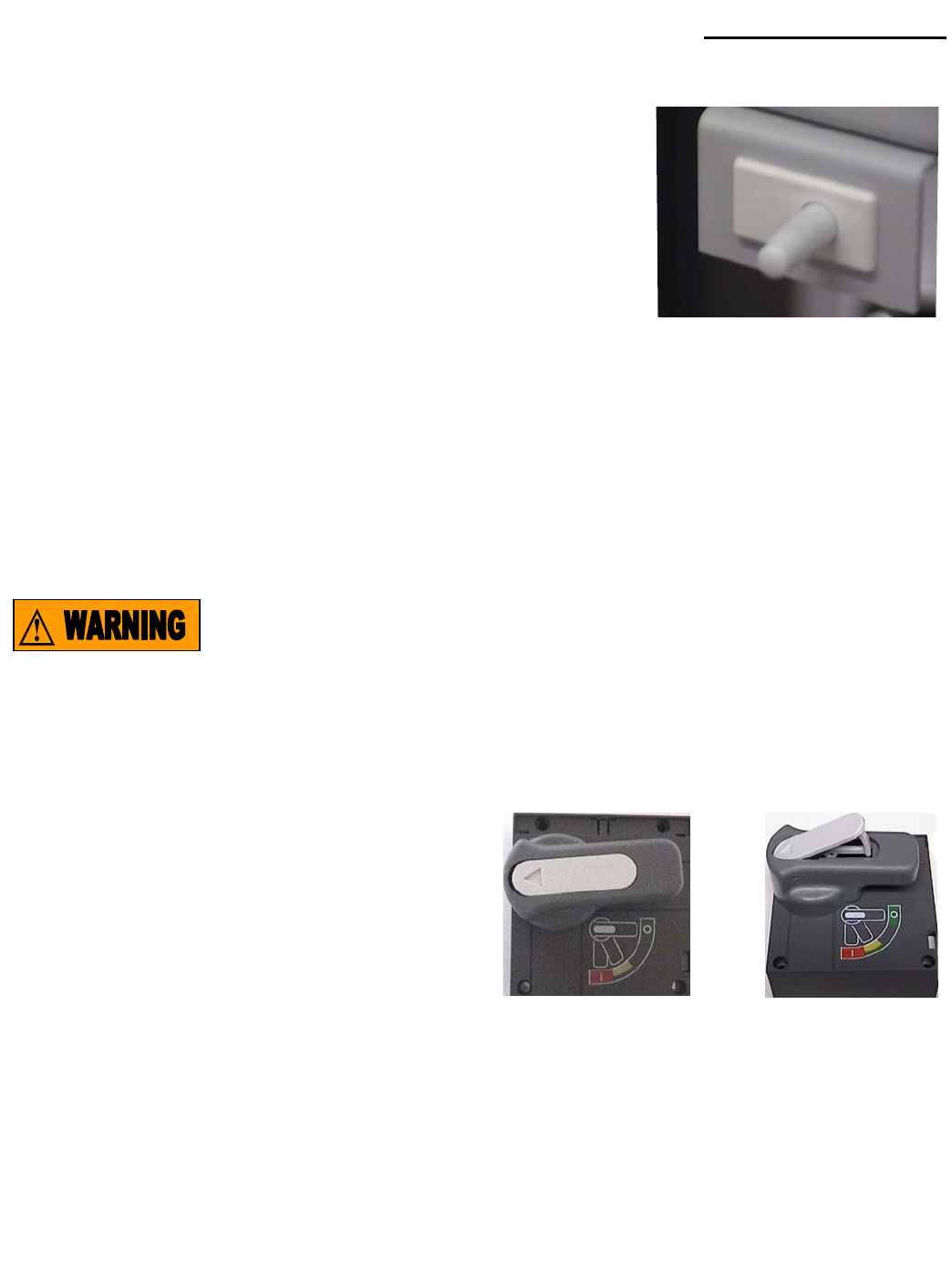

2.5 Lockout/Tagout

The rotary handle of the main breaker is equipped with a

hinged center insert clearly identified with an arrow. The

rotary handle of the main breaker must be in the horizontal

position to proceed. See Figure B. Depress the insert on

the arrow on the left hand side causing the insert to extend

on the right revealing a slot to accommodate a locking

device as shown in Figure C. The lockout/tagout feature is

designed to prevent personnel from accidentally energizing

the power conditioner while maintenance, service or repair

is being performed. With the lockout/tagout engaged, hazardous voltages are still present at the rear of the input

circuit breaker where input power feeds connect to the power conditioner. Entering the enclosure under these

circumstances is classified as a Type 4 Task under SEMI S2-0200. Entering the enclosure may be classified as

a Type 1 Task if power is disconnected from the power conditioner at the source.

Figure B Figure C

Section 2 - Safety

Figure A