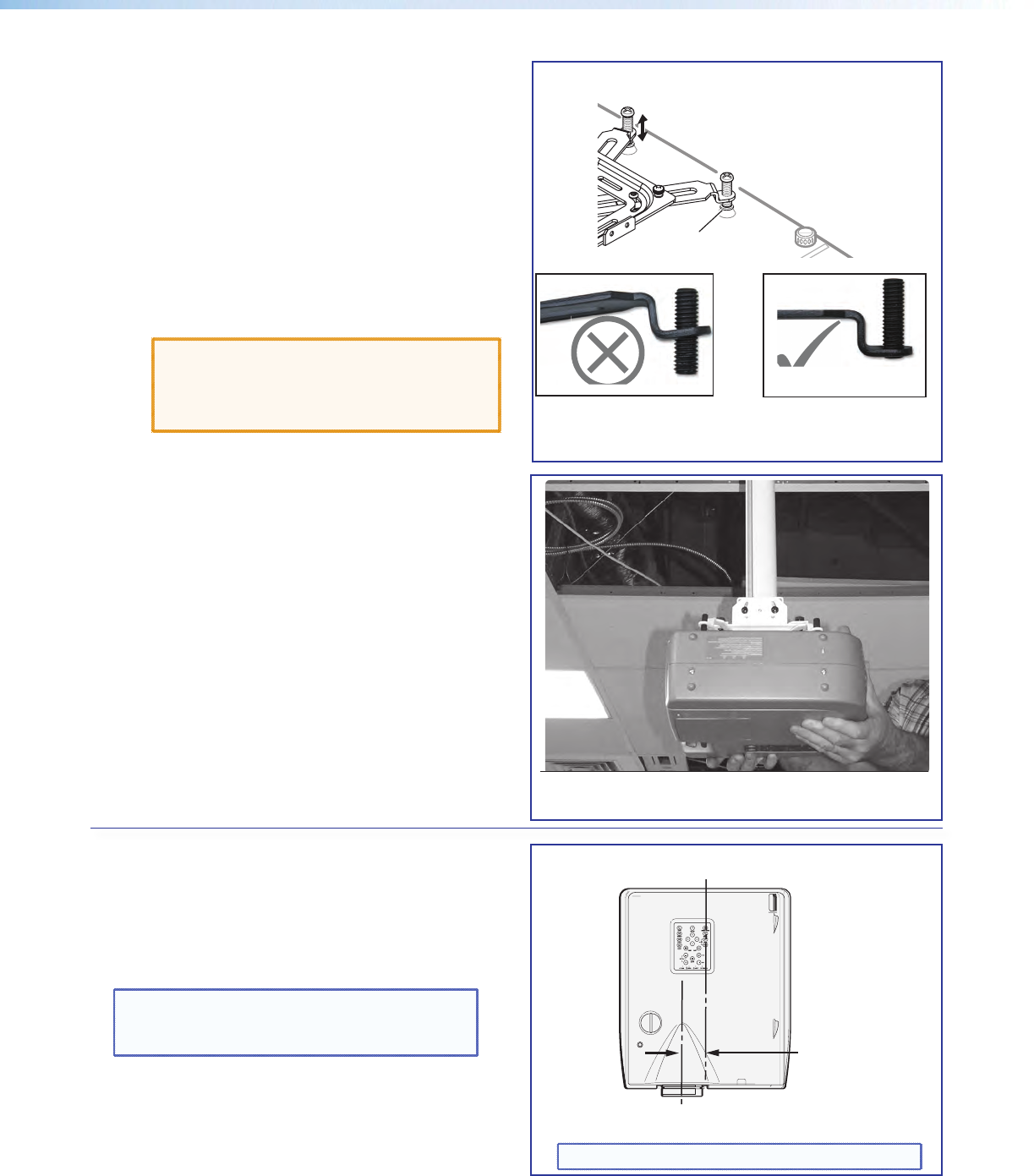

ix. Check for stress on the arms. To do this

loosen the mounting screws (do not remove).

If the arm or the barrel lifts, this indicates

stress on the arm. Adjust the height of the

threaded barrels to reduce or eliminate

any torque or stress that might be caused

by crossed arms or by projector mounting

points with differing heights. It is important to

keep the arms level and as close (low) to the

projector base as possible.

x. Check that the projector weight is still as

evenly distributed as possible.

Hand tighten the screws until snug.

ATTENTION: Do not overtighten the

mounting screws as this may damage the

projector. See the projector manual for the

threaded insert torque setting.

f. Lift the projector up to the adjuster plate and

slide it into place. Tighten down the locking and

pivot screws.

3. — Verify the Image Location

a. Connect a power cable to the projector and

turn it on.

b. Verify image size and location by loosening the

PCM 340 pipe adapter plate wing nuts, and

adjust the plate (left-right) to center the image.

TIP: Remember to include the vertical and

horizontal offsets when aligning the projector.

See the projector manual for information

c. When satisfied, tighten down the plate wing

nuts.

ß

Slide and lock the projector onto the

adjuster plate.

Projector

Center Line

Lens

Center Line

Measure the

horizontal offset

⊗

INCORRECT CORRECT

Arm not level, causing stress Arm level, no stress

on mounting point on mounting point

Loosen the screw and adjust

the barrel height to reduce torque

on the arms and bracket.

Tighten down all the

mounting screws.

Washer

TIP: Horizontal offset

PoleVault IP Systems • Installation — Stage 1 (Screen and Projector) 15