Operation

12 3A0415D

Installing Lubricator to

Lubrication Point

1. Clean the lubrication point to remove any

potential contaminants.

2. Verify the thread of the lubricator corre-

sponds to the thread of the screw point.

3. Verify Dip Switches are correctly set. See

Table 1, page 8.

4. Prime the grease line and all accessories

with the same grease that is contained in

the lubricator (See Parts, page 16 for a

complete list of available grease car-

tridges).

5. Install reducers, extensions, grease line,

etc. (if necessary).

6. Place drive unit on top of new lubrication

canister until the teeth of both pieces are

locked.

7. Screw the cover of the drive unit onto the

lubrication canister - hand tighten only.

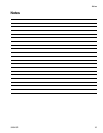

8. (If the plug is not

already removed),

remove the plug (A).

9. Install lubricator unit

into adapter (B) (if it is

not already installed).

10.Screw lubricator to

lubrication point,

hand tight only.

Operation

Before operation verify:

• The lubricator does not have any visible

damage.

• The lubricator canister is filled with the

requested grease or oil.

• For oil filled lubrication canisters, an oil

throttle must be attached.

• New batteries have been installed.

• The “VOL” switches 3 and 4 of the 4-way

code switch match the correct size of the

lubrication canister.

A

NOTICE

To ensure optimal lubrication:

• Seal threads of all connecting parts with a

suitable, standard sealant.

• Mount oil filled lubricators properly with the

outlet pointing down.

• Never screw in the lubricator a second time

or the self-sealing threads will be dam-

aged.

• For remote mounting installations, make

sure bracket does not squeeze the lubrica-

tion canister as this could block the piston

inside the canister.

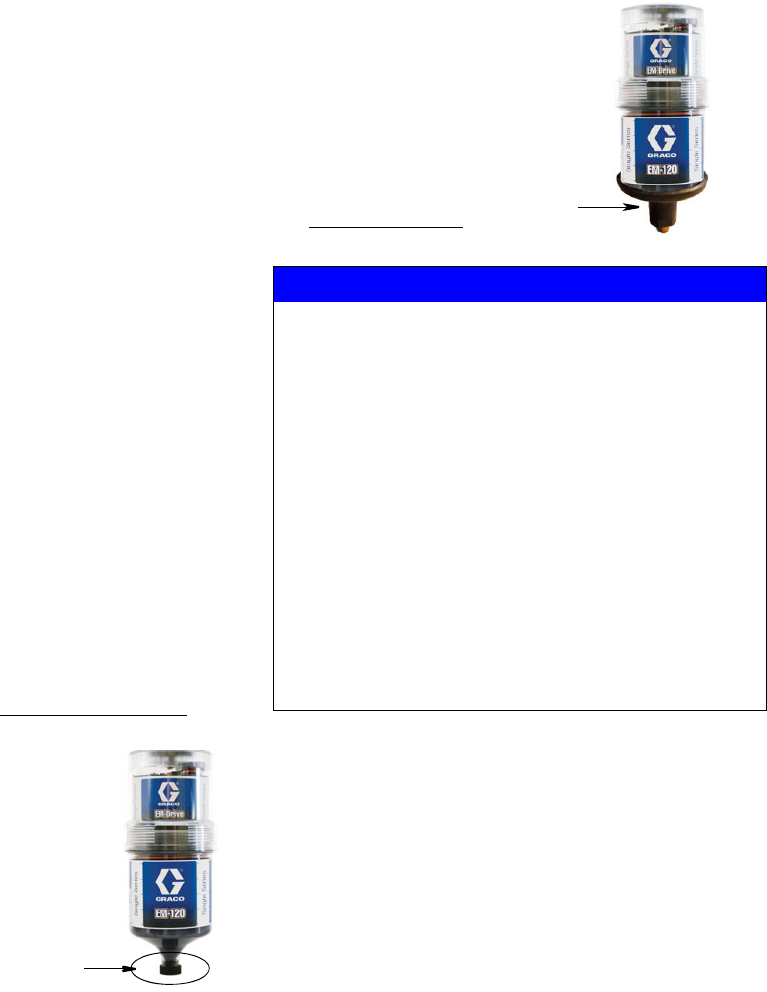

B