Setting Description If too low If too high

Input tension Tension is applied to the

substrate from the input spindle.

It needs to be constant over the

full width of the substrate, thus

substrate load is a critical

operation.

The substrate skews and may

become increasingly wrinkled in

the printing zone. Also, substrate

advance may be irregular,

resulting in horizontal banding.

The substrate may be

permanently deformed or

damaged. Substrate advance

problems may appear in extreme

cases.

Vacuum level The vacuum applied to the

substrate at the printing zone

helps to hold the substrate down

on the print platen, keeping the

distance to the printheads

constant.

The substrate may lift up off the

platen and touch the printheads.

This can smear the printed

image, cause a substrate jam or

even damage the printheads.

For sticky substrates, friction

could be too high and substrate

advance irregular, resulting in

horizontal banding or irregular

grainy patches.

Here are some more advanced settings, which you are not recommended to change, unless you have

problems that you cannot resolve any other way.

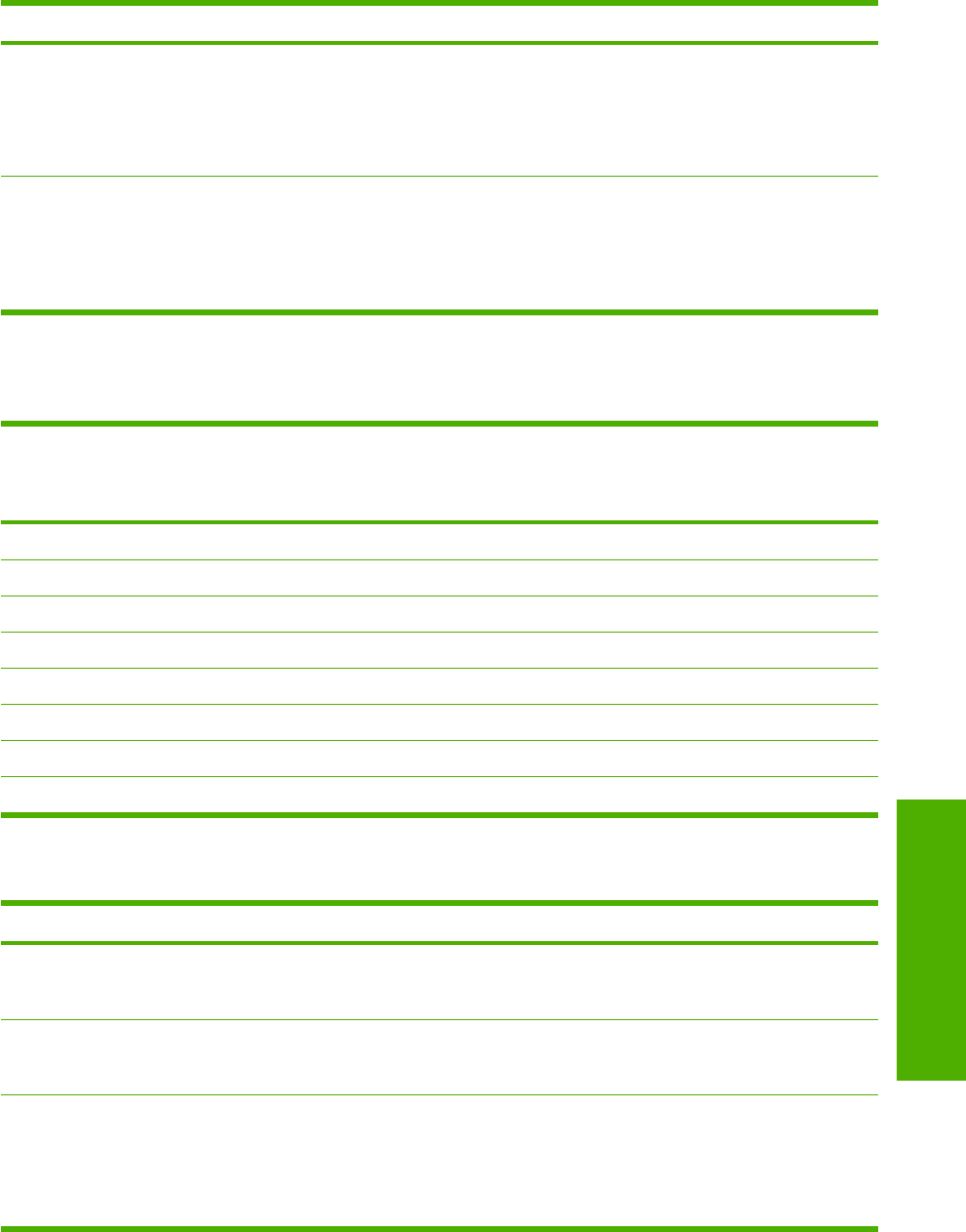

Substrate family Warm-up drying

temperature

offset

Warm-up curing

temperature

offset

Cool-down

drying

temperature

offset

Cool-down

curing

temperature

offset

Minimum drying

power

Self-adhesive vinyl 10 0 0 0 0.7

Banner 10 0 0 0 0.7

Film 5 0 0 0 0.7

Fabric 5 0 0 0 0.7

Mesh 10 0 0 0 0.7

Paper-Aqueous 5 0 0 0 0

Paper-Solvent 10 0 0 0 0.7

HP Photorealistic 10 0 0 0 0

The various settings mentioned above are described below.

Setting Description If too low If too high

Warm-up drying

temperature offset

The temperature that the

substrate in the print zone must

reach before printing starts.

Bleeding or coalescence may

appear in the first 200-300 mm of

the print.

A longer time to start printing is

required. Vertical banding or ink

smears may occur.

Warm-up curing

temperature offset

The temperature that the

substrate in the curing zone must

reach before printing starts.

The beginning of the print is not

fully dry, or looks oily.

Substrate degradation (bubbles,

adhesive detachment) at the

beginning of the print.

Cool-down drying

temperature offset

The safe temperature at which

the substrate can be under the

drying module without being

damaged. At the end of a job, the

substrate is not stopped until this

temperature is reached.

A long time is needed to finish the

print.

The substrate at the beginning of

the next print may be damaged,

because it has stopped moving

under too high a temperature.

This case is uncommon.

ENWW Add a new substrate type 35

Handle the substrate