Appendix-18

Transparencies

Transparencies must be able to withstand the heat of printing. Transparencies must meet the following

conditions.

To avoid problems, use the multi purpose tray for transparencies and load transparencies with the long side

facing the machine.

If transparencies jam frequently at output, try pulling the leading edge of sheets gently as they are ejected.

Hagaki

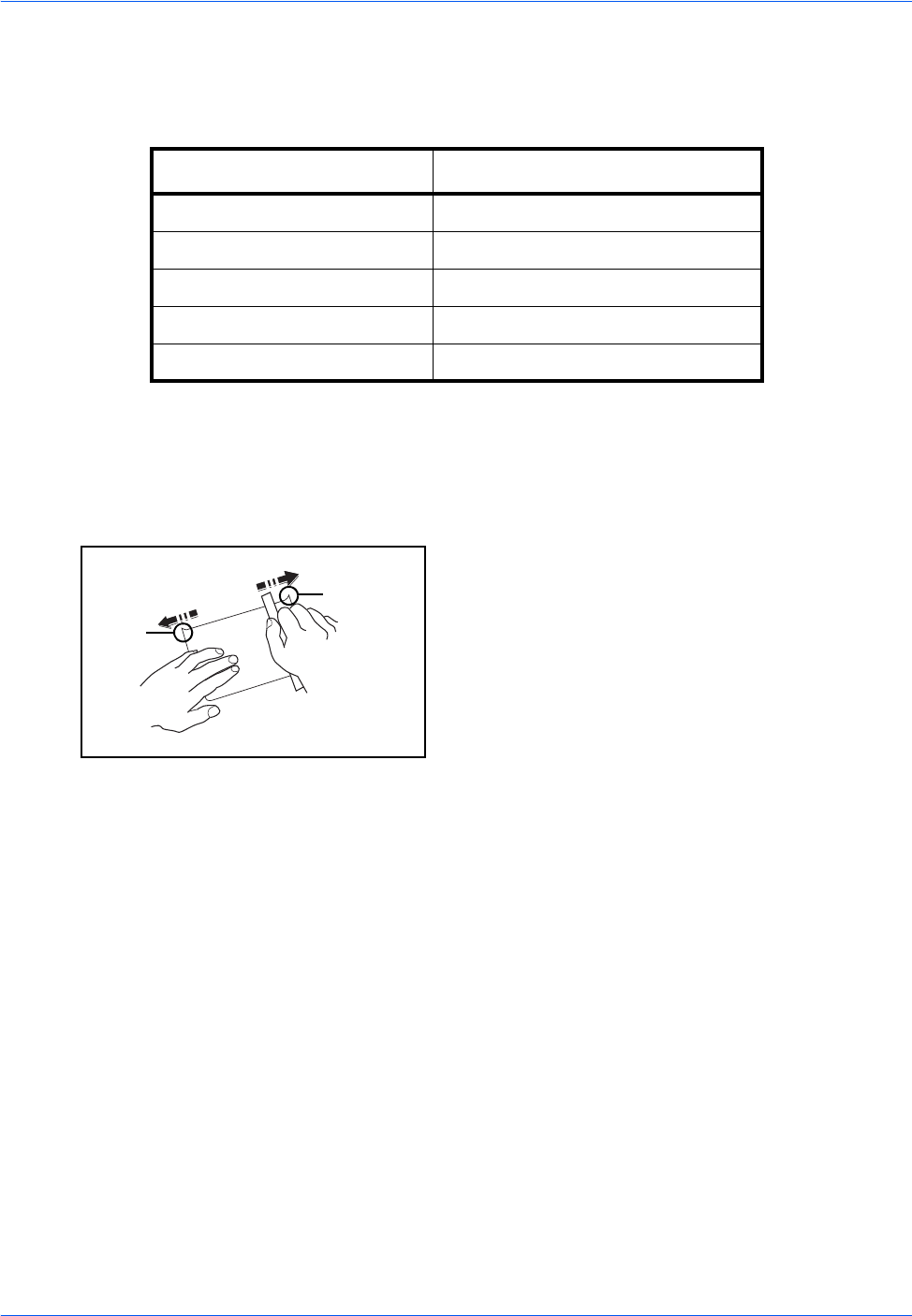

Before loading Hagaki into the multi purpose tray, fan

them and align the edges. If the Hagaki paper is curled,

straighten it before loading. Printing onto curled Hagaki

may cause jams.

Use unfolded Oufuku hagaki (available at post offices).

Some Hagaki may still have rough edges developed by

a paper cutter on the back side. Remove any such

rough edges by placing the Hagaki on a flat surface and

rubbing the edges gently a few times with a ruler.

Envelopes

Use the multi purpose tray for envelopes.

Due to the structure of envelopes, printing evenly over the entire surface may not be possible in some cases.

Thin envelopes in particular may be wrinkled by the machine in some cases as they pass through. Before

purchasing envelopes in volume, try testing a sample to ensure the print quality.

Storing envelopes for a long period may cause them to become wrinkled. Thus, keep the package sealed until

you are ready to use them.

Keep the following points in mind.

Do not use envelopes with exposed adhesive. In addition, do not use the type of envelope in which the adhesive

is exposed after the top layer is peeled off. Serious damage may be caused if the paper covering the adhesive

comes off in the machine.

Do not use envelopes with certain special features. For example, do not use envelopes with a grommet for

winding a string to close the flap or envelopes with an open or film-covered window.

If paper jams occur, load fewer envelopes at once.

To prevent paper jams when printing onto multiple envelopes, do not allow more than ten envelopes to remain

in the output tray at once.

Criteria Specifications

Heat resistance Must withstand at least 190°C

Thickness 0.100 to 0.110 mm

Material Polyester

Dimensional accuracy ±0.7 mm

Squareness of corners 90° ±0.2°

Burrs

Burrs