3

-

1.

POWER

SWITCH

(Figure

3-1)

3

-

4.

VOLTMETER

(Figure

3-1)

Placing

the

POWER

switch

in

the

ON

position

applies

input

power

to

the interface.

The

interface

must

be

on

for

the

robot

to

weld.

Placing

the

POWER

switch

in

the

OFF

position

shuts down

the interface.

3

-2.

INDUCTANCE

CONTROL

(Figure

2-1)

The

INDUCTANCE

control

is

a

digital

pushbutton

con

-

trol

which

can

be

set

for

inductance

levels

1

through

7.

As

the

level

of

inductance

increases,

the

rate of

change

of

the

weld

output

or

speed

of

response

slows

down.

The

slower

response

time

produces

a

softer

arc,

more

fluid

welding

puddle,

and

flatter,

smoother

bead.

The

0

(zero)

setting gives

minimum

inductance,

i.e.,

a

stiff,

fast-responding

arc, and

a

small,

fast-freezing

puddle.

The

7

setting

gives

maximum inductance

characteristics,

i.e.,

a

soft,

slow-responding,

low

spat-

ter

arc, and

high

weld

puddle

fluidity.

Select

a

setting

best

suited

for

the

application.

3

-

3.

OVERLOAD

PROTECTION

(Figure

3-1)

A.

Fuse

Protection

The

interface

is

protected

from

damage

due

to

an

inter

-

nal

short

or

excessive

overload by fuse

Fl.

If

fuse

Fl

opens,

the

interface

shuts

down.

See

Section

5-2

for

replacement

procedures.

B.

Wire

Drive

Motor

Circuit

Breaker

The

wire

drive

motor

is

protected

from

damage

due to

overload

by

circuit

breaker

CB1. If

CB1

opens,

the

inter-

face

shuts

down.

Manually

depress

the

reset

button

to

reset

the

circuit

breaker.

The

voltmeter

displays

weld

voltage

to

the

nearest tenth

of

a

volt while

welding

and preset

voltage

while

idling.

3

-5.

WIRE

SPEED

METER

(Figure

3-1)

The

wire

speed

meter

displays

preset

wire

feed

speed

to

the

nearest

inch

per

minute while

welding

and

idling.

Actual

and preset

wire

feed speed

are

the

same

due

to

the

wire

feed

speed

feedback

circuit.

3

-

6.

AMMETER

(Figure

3-1)

The

ammeter

displays

weld

amperage

to

the

nearest

amp

while

welding

and preset

amperage

while

idling.

3

-

7.

INDICATOR

LIGHTS

(Figure

3-1)

There

are

five

indicator

lights

on

the interface.

These

are

visual

indications

of

various

process

functions.

The

GAS

light

turns

on

when

the

gas

valve

is

energized

to indicate

shielding

gas

flow.

The

CONTACTOR

light

turns

on

when

the

welding

power

source

contactor

is

energized

to indicate that

weld

output

is

available.

The

WIRE

FEED

light

turns

on

when

the

wire

drive

motor

is

energized

to indicate that

wire

is

feeding.

The

CURRENT

light

turns

on

when

the

current

detect

relay

is

energized

to indicate that

an

arc

is

established.

The

ARC

FAILURE

light

turns

on

when there

is

an

arc

outage while

welding.

SECTION

4

-

SEQUENCE

OF

OPERATION

Arc

Initiation

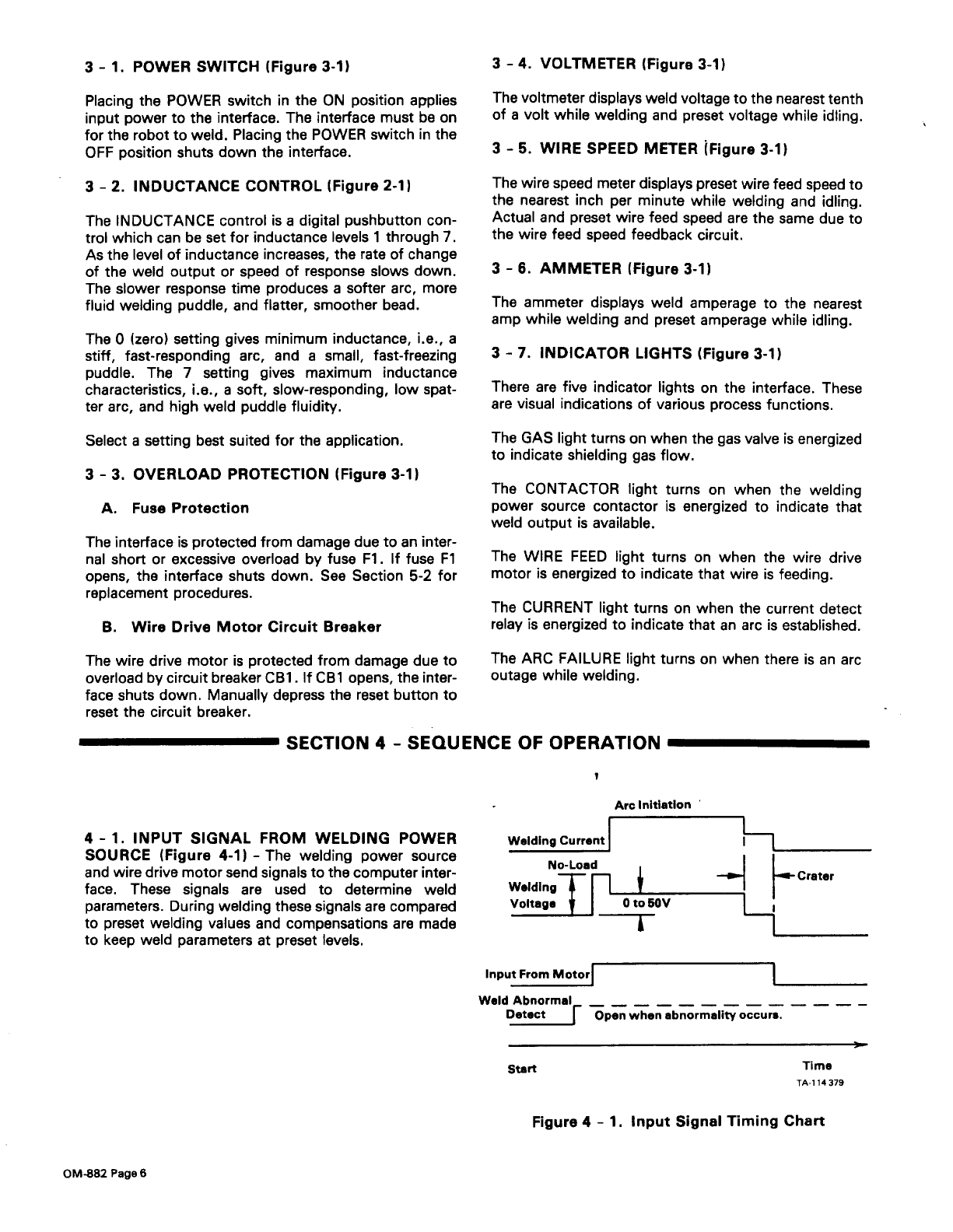

4

-1.

INPUT

SIGNAL

FROM

WELDING

POWER

SOURCE

(Figure

4-1)

-

The welding

power

source

and

wire

drive

motor

send

signals

to

the

computer

inter-

face.

These

signals

are

used

to

determine

weld

parameters.

During

welding

these

signals

are

compared

to

preset

welding

values

and

compensations

are

made

to

keep

weld

parameters

at

preset

levels.

Welding

Current

No-Load

WeldingT~

Voltage

0

to 50V

—F

WeldAbnormal

—

D~LY

Open when

abnormality

occurs.

Start

Time

TA-i

14

379

Figure

4

-

1.

Input

Signal

Timing

Chart

H-

Crater

OM-882

Page6