4

-

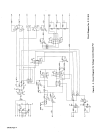

2.

OUTPUT

SIGNALS

FROM

COMPUTER

IN

-

TERFACE

(Figure

4-2)

-

The

interface

interprets

the

input

signals

from

the

welding

power

source,

wire

drive

motor,

robot,

and

wire

stick

check

circuit.

The

output

of

the

computer

interface

regulates the

welding

power

source

and

wire

feed

functions

while

welding.

Wire

Start

Relay

Arc

Initiation

Open

Close

I I

1OVDC

5VDC

2.5VDC

I

Voltage

1

.25VDC

I I

Command

TA-i

14

378

Figure

4

-

2.

Output

Signal

Timing Chart

4

-

3.

WIRE

STICK

CHECK

(Figure

4-3)

-

After

the

weld

is

completed,

the

wire

stick

check

is

performed

to

determine

if

the

welding

wire

has

burned

back

out

of

the

weld

puddle.

Feedback

is

used

to

determine

if

the

wire

is

free of

the

weld.

If

the

feedback

indicates

the

wire

is

free of

the

weld,

the

robot

can

cycle

to

its

next

sequence.

If

the

feedback

indicates

the

wire

is

stuck,

the

welding

power

source

is

sent

a

1

.25

VDC

command

signal

to

provide

minimum welding

power

source

output.

The

contactor

is

pulsed

on.

If

the

wire

was stuck,

the

pulsed

voltage

should

be

enough to free

the wire.

Feedback

is

used

to

determine

if

the

wire

is

now

free of

the

weld.

If

the

feedback

indicates

the

wire

is free,

the

robot

can

cy

-

cle

to

its

next

sequence.

If

the

feedback

indicates

the

wire

is

still

stuck,

a

higher

voltage

command

is given,

and

the

contactor

pulsed

to

free

the

welding

wire.

The

check is performed

and

two

more

voltage

increases

are

used

to

try

and

free

the

welding

wire

(see

Figure

4-3).

If

the

wire

remains

stuck,

the

robot

will

shut down,

a

Weld

Abnormal error

will

be

displayed

on

the

robot

pro

-

gram

module,

and

the

wire

must

be

physically

removed

from

the

weld.

SECTION

5

-

MAINTENANCE

&

TROUBLESHOOTING

•~j~j~~j5

Every

six

months

inspect

the

labels

on

this

unit

for

legibility.

All

precautionary

labels

must

be

maintained

in

a

clearly

readable

state

and

replaced

when

necessary.

See

the

Parts List

forpart

number

of

precautionary

labels.

5

-

1.

INSPECTION

AND

UPKEEP

1.

Repair

or

replace, as

required,

all

hoses,

cords,

and

cables; give

particular

attention

to

frayed

and

cracked insulation

and

areas

where

it

enters

equipment.

2.

Remove grease

and

grime

from

components;

moisture

from

electrical

parts

and

cables.

WARNING:

ELECTRIC

SHOCK

can kill.

•

Do

not

touch live electrical

parts.

•

Shut

down

unit,

welding

power

source,

and

robot

and

disconnect

input

power

employing

‘lockout/tagging

procedures”

before

internally

inspecting

or

servicing.

Lockout/tagging

procedures

consist

of

padlocking

line

disconnect

switch

in

open

position,

removing

fuses

from

fuse box,

or

shutting off

and

red-tagging

circuit

breaker

or

other disconnecting

device.

Usage

and

shop

conditions

will

determine

the

frequency

and

type

of

maintenance.

Inspect

equipment

as

follows:

5

-

2. OVERLOAD PROTECTION

(Figure

3-1)

WARNING:

ELECTRIC

SHOCK

can kill.

•

Do

not

touch

live electrical

parts.

•

Shut

down

unit,

welding

power

source,

and

robot

and

disconnect

input

power

employing

“lockout/tagging

procedures”

before

internally

inspecting

or

servicing.

Lockout/tagging

procedures consist

of

padlocking

line

disconnect

switch

in

open

position,

removing

fuses

from

fuse box,

or

shutting off

and

red-tagging

circuit

breaker

or

other disconnecting device.

Close

I

~~chlng~

Open

TA~1

14

379

I I I

Output To

Motor

Figure

4

-

3.

Wire

Stick

Check

Start

OM-882

Page

7