19

When swapping a new card for an old card, it is important to note that the 8610 DSLAM

retains the Media Access Control (MAC) address, also referred to as the physical

address. This means that the new card will have the same MAC address as the old

one.

NOTES:

— All standalone 8610 chassis (i.e., chassis that are not daisy-chained to other

Hotwire 8610 DSLAM chassis) require an MCP card in Slot 1, but only the

base chassis of a multisystem stack requires an MCP card.

— Do not discard filler plates. Each slot in the chassis must contain a circuit card

or a filler plate to maintain the required EMI shielding and to prevent air

leakage from the forced air cooling. Air leakage could result in overheating

which may cause the power to the circuit cards to be shut off. Store all unused

filler plates in a safe place. You may need to use the filler plates to cover open

slots in the chassis at a later time.

" Procedure

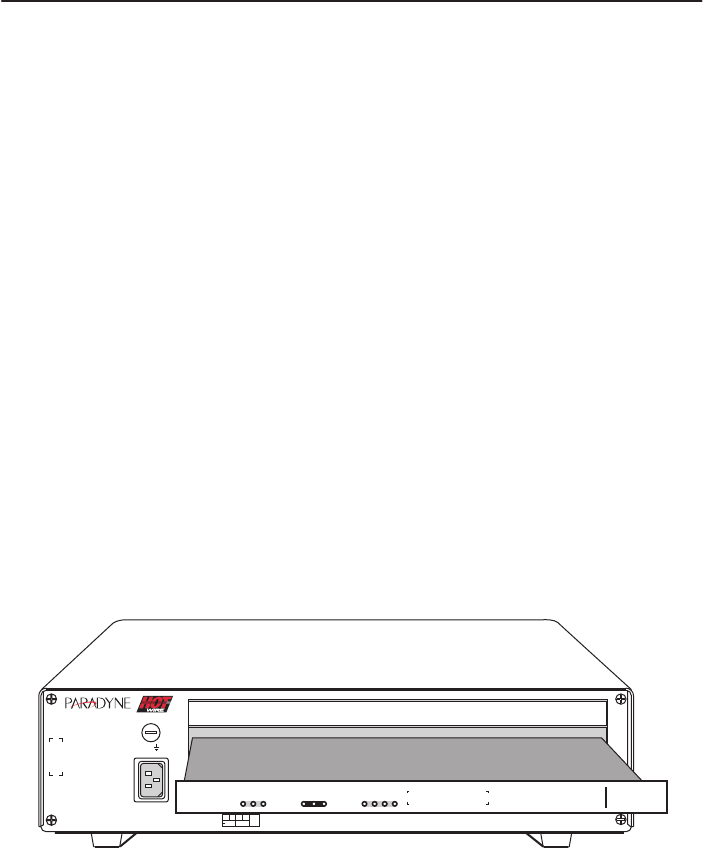

To install a circuit card in the Hotwire 8610 DSLAM chassis:

1. Remove the filler plate from the slot by unscrewing the mounting screws at each

end.

2. Hold the card horizontally with the components on top, and insert it into the left and

right card guides of the slot of the base chassis.

99-16321

TM

TM

STACK

POSITION

2

3

6

5

4

1

AC

INPUT

1

2

3

ESDESD

48VDC CLASS 2

OR LIMITED

PWR SOURCE

48V

A

RTN

ABB

A

B

DC FUSES

T4A, MIN. 48V

PWR

A

ALM

FAN

B

OUTIN SERIAL

ALM INTF

MCP/1

2

3

MCP/

DSL

MANAGEMENT

10 BASE T

8610

MCP

8000

SYSTEM

OK

Alrm

Test

TX

RX

Coll

ETHERNET

RADSL

8000

SYSTEM

OK

Alrm

Test

TX

RX

Col

1

2

3

4

ETHERNET

DSL PORT

3. Carefully slide the card into the slot. Gently, but firmly, push the card until it

engages its mating connectors on the backplane.

4. Press on the card’s front panel with one hand and on the back of the 8610 chassis

with the other until the card’s connector seats in its mating connector.

5. Make sure the OK SYSTEM indicator on the card’s faceplate is ON (green). If not,

refer to

Troubleshooting

on page 25.

6. Secure the card by fastening the screws on each end of the faceplate. This is

required to maintain proper gasket pressure on the faceplate as well as proper air

flow.