A470e Users Guide

Pertech® 2006

9

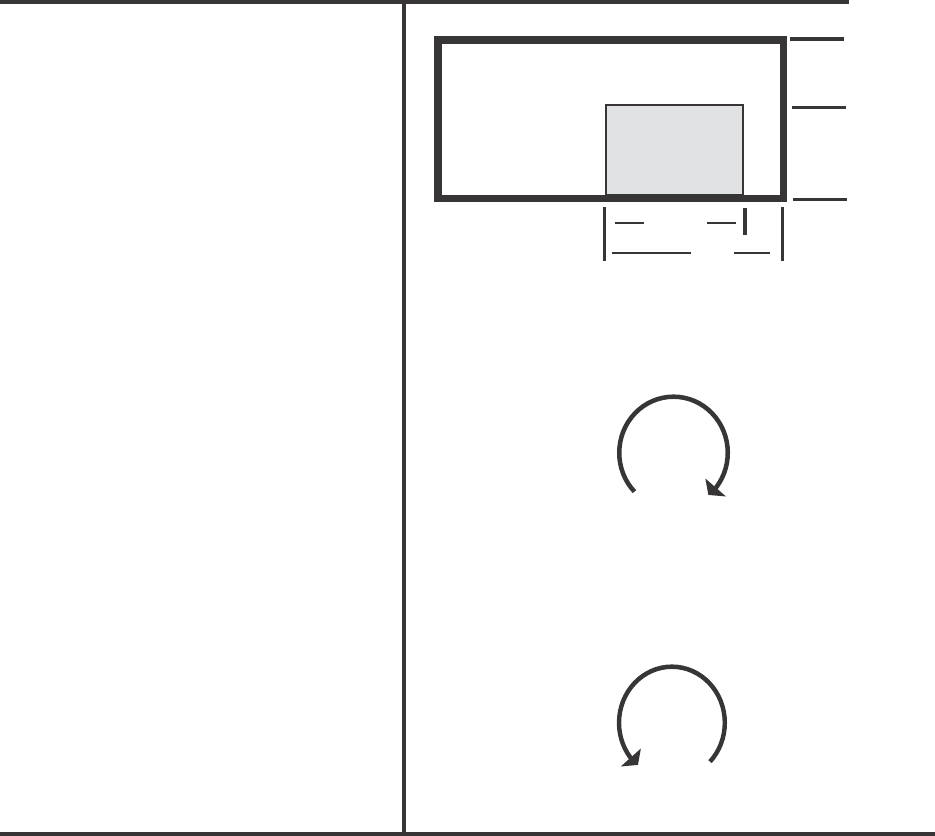

The Document Stop limits the depth an inserted form can be placed into the Validation Slot. This

denes the validation printeld height. Printers are manufactured with the maximum printeld

setting of 2.16 inches but the dimension can be reduced to 1.44 inches by turning a slotted

screw in the bottom of the printer case counter-clockwise (CCW). Each CCW revolution raises

the document stop and decreases the printeld height 1/32” (.03125”) or .79375 mm. DO NOT

ATTEMPT TO ADJUST THE DOCUMENT STOP OUTSIDE THE PRESCRIBED LIMITS OR

DAMAGE TO THE PRINTER COULD RESULT. The validation form must be at least 1 inch taller

than the selected printeld.

Printeld Height

Ccw Rev Inches Mm

0 2.16 54.9

1 2.13 54.1

2 2.10 53.3

3 2.07 52.5

4 2.04 51.7

5 2.00 50.9

6 1.97 50.1

7 1.94 49.3

8 1.91 48.5

9 1.88 47.7

10 1.85 46.9

11 1.82 46.1

12 1.79 45.3

13 1.75 44.5

14 1.72 43.8

15 1.69 43.0

16 1.66 42.2

17 1.63 41.4

18 1.60 40.6

19 1.57 39.8

20 1.54 39.

21 1.50 38.2

22 1.47 37.4

23 1.44 36.6

CW

Clockwise rotating lowers the

document stop and increases the

print eld.

CCW

Counter clockwise rotation raises

the document stop and decreases

the print eld.

2.78"

3.6"

Print

Field

1" Min.

Validation

Printfield

Verication of the desired document stop setting can be made by printing a Conguration

Report Self Test on validation media and measuring the printeld. A Conguration Report Self

Test is initialized by turning the printer power off, pressing and holding the Paper Feed Button,

inserting a form into the printer and turning the power back on. The validation rollers can be

opened manually by raising the printer cover and pressing downward on the yellow sector gear

if the printer will not accept a form. The printeld dimension is measured from the top of the

rst line of print to the bottom of the form.

Document Stop Adjustment