Paper Specifications C-7

Recycled Paper

Recycled paper is made from used paper. The used paper is dissolved into fibers and

then mixed with new paper fibers. However, various kinds of low-grade used paper

(such as newspapers and magazines) are added to high-grade old paper. The paper

manufacturer must have a high level of expertise and exercise strict controls regarding

the use of used paper in recycled paper production. Therefore, it is recommended that

paper sold as xerographic recycled paper also be sufficiently tested before using. The

most important factor is the length of time the paper can keep its stabilized quality. It

is recommended that a small sample (about 2,000 sheets) of recycled paper be tested in

the printer and the reliability in paper feed and print quality is confirmed continuously

over several months.

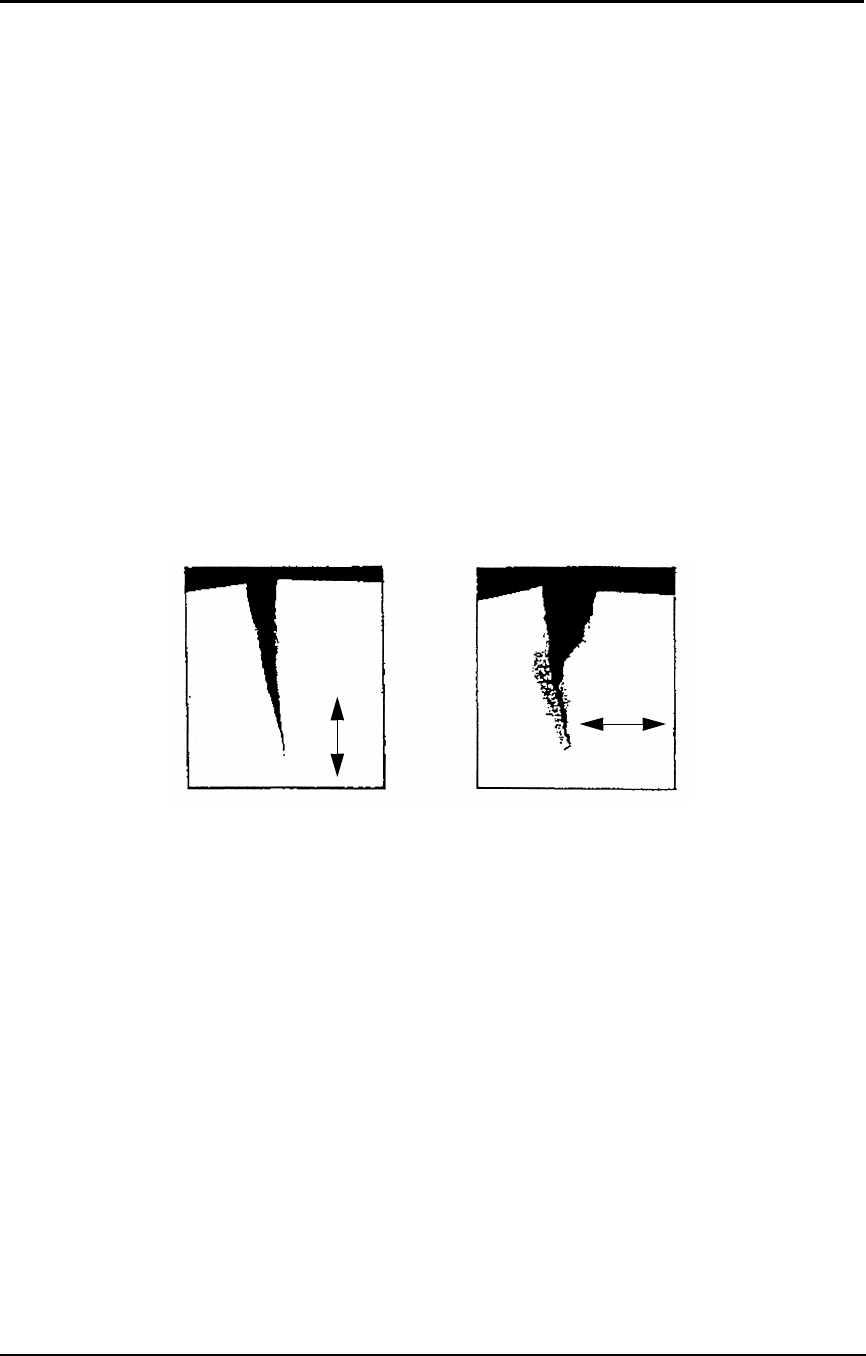

Grain Direction

The direction of paper fibers greatly affects paper curl and deformation. High quality

xerographic paper is manufactured with the fibers oriented evenly in the same direction

(grain long). The direction of the grain can be determined by tearing the paper. A clean

tear indicates the grain direction as shown below.

Paper Smoothness

Paper smoothness affects print quality and paper handling. Paper should not have a

rough texture. A rough texture provides poor toner adhesion, particularly in “black fill”

areas. Neither should the paper be too smooth, as this can also affect toner adhesion.

Paper that is too smooth has inadequate friction and can cause paper handling

difficulties. Do not use paper with embossed or raised surfaces. Spotty printing and

misfeeding may occur.

Grain

Direction

Grain

Direction