Unit 6: Maintenance

S8400 Series Operator Manual

6-8 PN: 9001160B

PRINT HEAD PRESSURE

Print head pressure is the equalization of pressure against the platen roller from one end to the opposite. If the print

head balance is out of adjustment, the printed image will be darker on one side of the label than the other and the

media will be prone to travel in the direction of least resistance.

The adjustment of print head pressure is achieved through the adjustment of a four-position dial located within the

print assembly just above the print head. The end of the dial is inumerated 1 through 4.

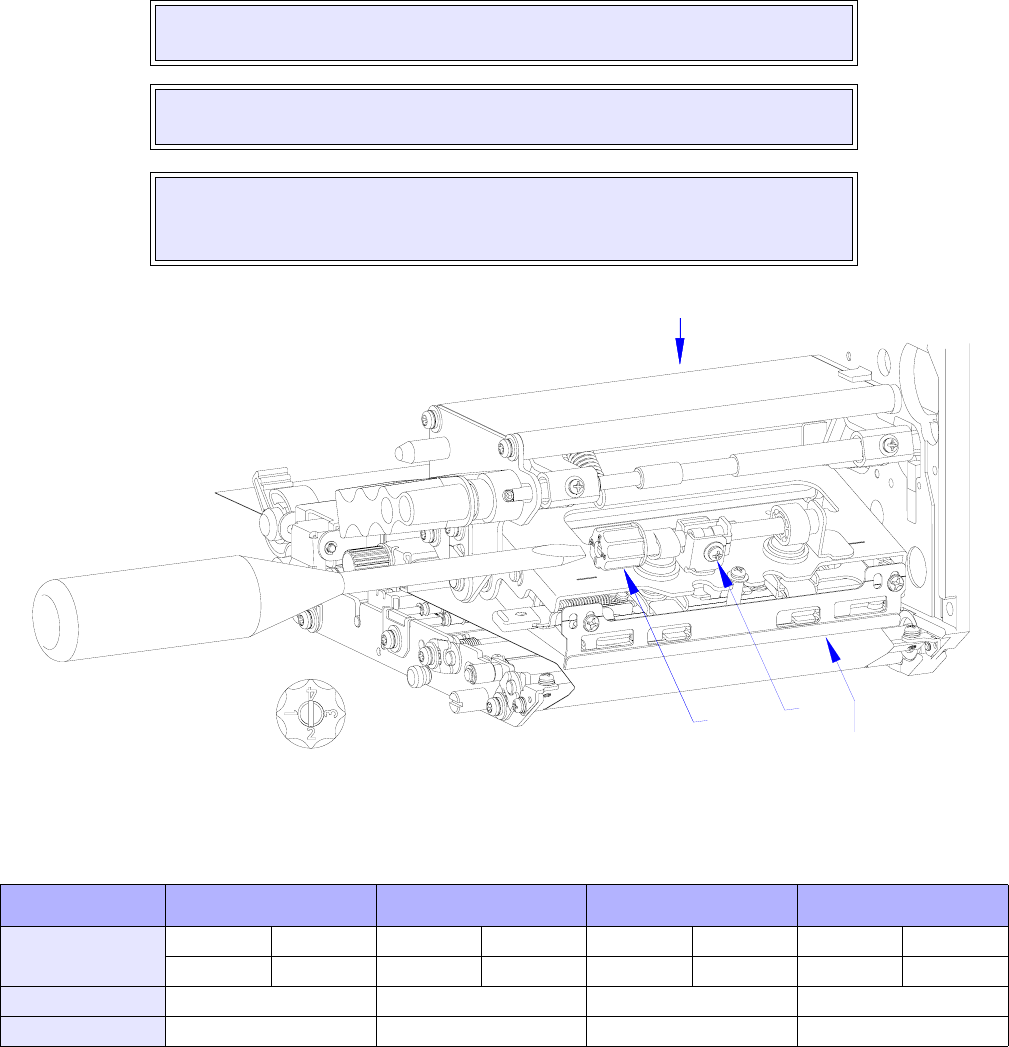

To adjust the pressure, begin test printing and slightly loosen set screw (1, Figure 6-6). Then rotate dial (2) to each

position and monitor printing characteristics for each position. Optimum pressure is achieved by the disappearance

or reduction of prevailing negative print characteristics. Retighten set screw (1) when the best dial position is

chosen.

Figure 6-6, Print Head Pressure Adjustment

NOTE: For reference purposes, the embossed number on the dial’s end that is

positioned closest to the print head is the dial setting.

NOTE: If the dial is too difficult to manually adjust using fingertips. A slotted

screwdriver may be inserted into its end for easier dial rotation.

ATTENTION: If some print problems persist, the print head alignment may

require adjustment. Following print head alignment, the print head balance

may require a different setting and the procedure repeated.

POSITION 1 2 3 4

Pressure Inside Outside Inside Outside Inside Outside Inside Outside

2.5kg 2.5kg 3.0kg 3.0kg 2.5kg 2.5kg 3.0kg 2.0kg

Label Width 30mm to 128mm 30mm to 128mm 10mm to 30mm 10mm to 30mm

Label Thickness 0.05mm to 0.20mm 0.20mm to 0.31mm 0.05mm to 0.20mm 0.20mm to 0.31mm

Print Assembly

Print Head

5

5