Unit 6: Maintenance

S8400 Series Operator Manual

6-11 PN: 9001160B

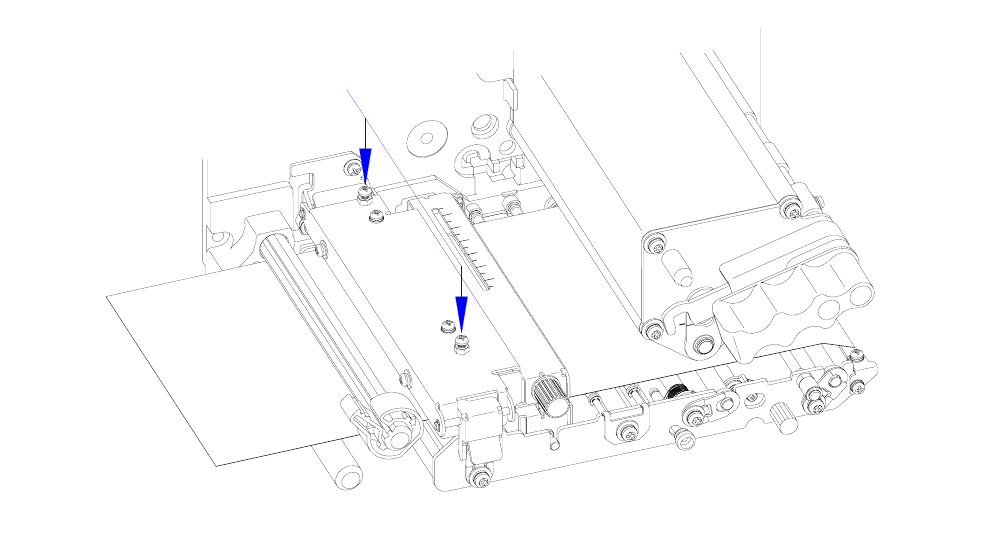

MEDIA PRESSURE ROLLER BALANCE

Pressure roller balance adjustment may be required if the media is inclined to meander at the printer’s rear to one

side. When all things are properly aligned and balanced, the media will continuously feed from the printer’s rear,

through to its front without lateral movement creating resistance on its left or right sides.

Before adjusting the pressure rollers, ensure the media roll is harmoniously positioned and aligned so that it may

flow perfectly parallel to the printer. Next, ensure the printer’s print head is properly aligned and balanced. If all

other conditions are confirmed to be adequate and the media’s edge is still dragging against either the printer’s

center wall or the media guide, then adjust the pressure roller balance.

These pressure rollers are spring loaded on each end and embedded in the label sensor assembly. By adjusting

the setscrew on either end downward, the pressure on that end is increased. Likewise, an adjustment of a

setscrew upward on either end, reduces pressure on that side.

To adjust pressure roller balance, loosen the locknut on given side and adjust the relative setscrew to increase or

decrease pressure as deemded appropriate. When the desired outcome is achieved, hold the setscrew in position

while tightening its locknut.

Figure 6-9, Media Pressure Roller Balance

Locknut/Setscrew