Unit 6: Maintenance

S8400 Series Operator Manual

6-4 PN: 9001160B

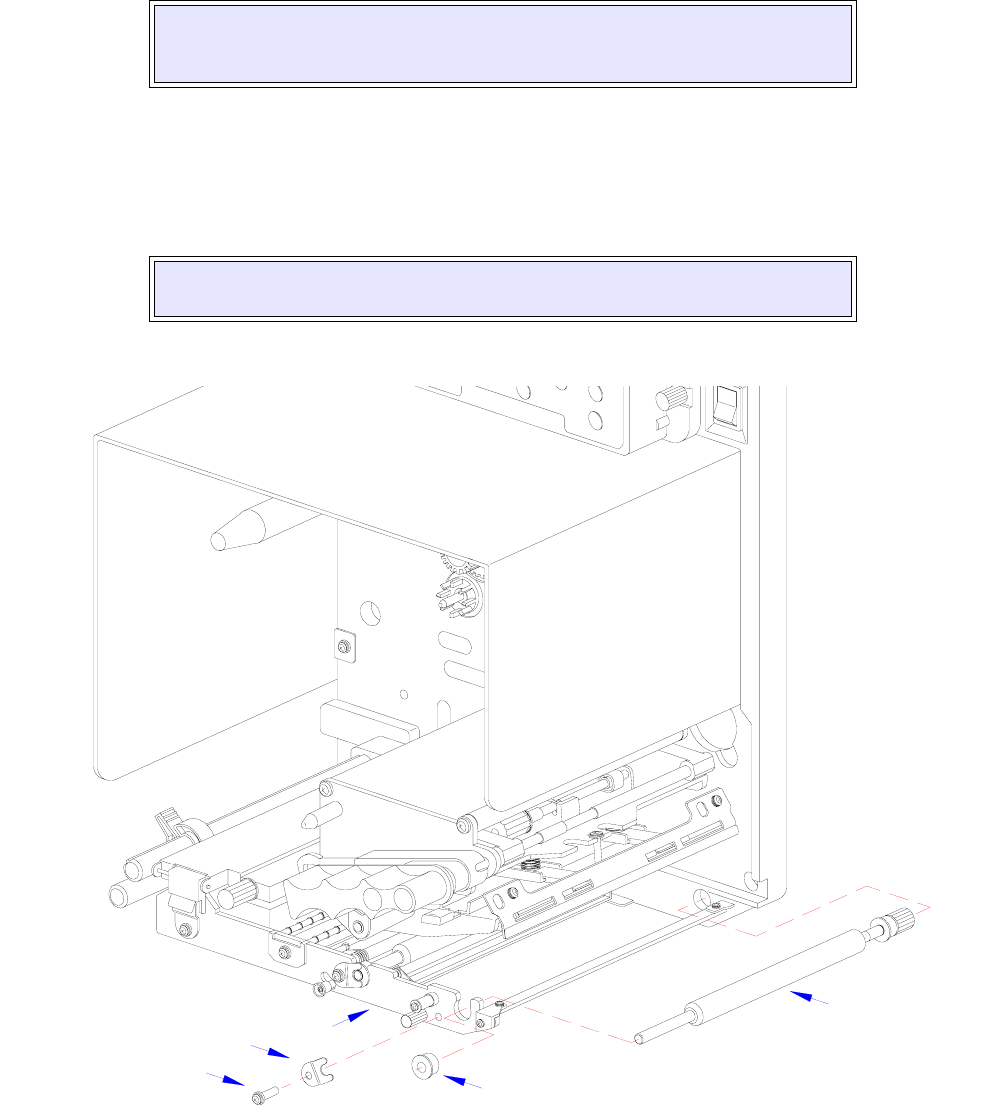

PLATEN ROLLER REPLACEMENT

The printer’s platen roller is considered to be a high-wear component due to constant treading of the print media

and ribbon stock against its contact surface. This constant contact will eventually wear grooves into the rubber

material and negatively effect print output. This procedure applies to all three rubber rollers.

1. Switch off the printer and observe appropriate lockout-tagout procedures.

2. Remove label media as required.

3. Loosen screw (1, Figure 6-2) sufficiently to rotate bearing clamp (2) from bearing (3).

4. Withdraw bearing (3) from chassis (4) and worn roller (5).

5. Withdraw worn roller (5) from the printer and insert replacement roller (5) in its place.

6. Insert bearing (3) onto the free end of replacement roller (5) to nest against chassis (4).

7. Rotate bearing clamp (2) onto bearing (3) and secure screw (1).

8. Repeat steps 3 through 8 as required and restore power.

Figure 6-2, Platen Roller Replacement

NOTE: Figure 7-2 shows screw (1) and bearing clamp (2) as being removed for

display purposes only. It is not necessary to remove those components for roller

replacement.

NOTE: Ensure the platen roller assembly is fully nested in the printer’s center frame

when screw (1) is secured.

2

3

4

1

5