3. TROUBLESHOOTING EO18-33021

3. TROUBLESHOOTING

3- 1

3. TROUBLESHOOTING

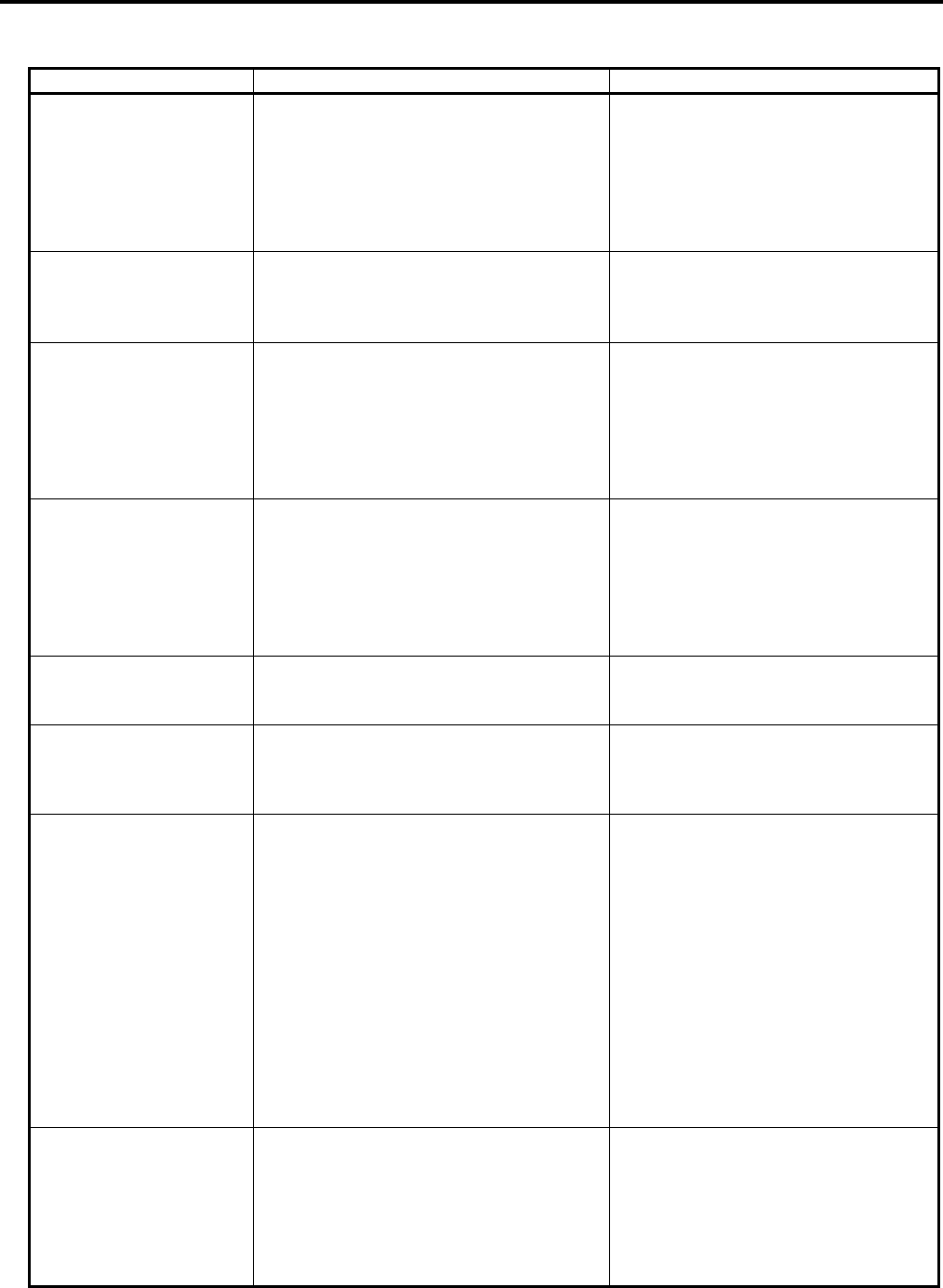

Problems Cause Solution

Power is not turned ON. 1. Input voltage to the printer is not

within the rated voltage.

2. Output voltage from the printer is not

within the rated voltage.

3. MAIN PC Board is not applied with

voltage.

4. Failure of MAIN PC board.

Replace the power cord or power

inlet.

Replace the PS unit.

Replace the power harness.

Replace the MAIN PC board.

LED does not light. 1. Failure of the KEYLED PC board.

2. Failure of the KEYLED harness.

3. Failure of the MAIN PC board.

Replace the KEYLED PC board.

Replace the KEYLED harness.

Replace the MAIN PC board.

Poor printing. 1. The print paper is of poor quality.

2. Dirty print head.

3. The head lever fastens the print head

incompletely.

4. Alignment adjustment of the print

head is improper.

Use the paper approved by

TOSHIBA TEC.

Clean the print head.

Fasten the head lever completely.

Re-adjust the print head.

Printer does not print. 1. Print head failure.

2. Connection of the print head

connector is incomplete, a bad

contact, or broken wires.

3. Failure of the MAIN PC board.

4. Failure of the software.

5. Failure of the printer cable.

Replace the print head.

Connect the harness completely,

or replace the harness.

Replace the MAIN PC board.

Check the program.

Replace the printer cable.

Dot missing. 1. Broken element of the print head.

2. Broken wires of the print head cable.

3. Failure of the MAIN PC board.

Replace the print head.

Replace the print head harness.

Replace the MAIN PC board.

Blurred print. 1. Poor quality of paper.

2. Dust is attached to the paper.

Use only TOSHIBA TEC specified

paper.

Clean the print head and remove

the dust from the paper.

Label feed failure. 1. Paper is not set properly.

2. Paper of poor quality.

3. Improper adjustment of the feed gap

sensor or black mark sensor.

4. Failure of the feed gap sensor or

blackmark sensor.

5. Labels cannot be stripped off the

backing paper or the backing paper

with labels cannot be would properly.

6. The cutter mechanism is not installed

properly.

7. Failure of the stepping motor.

Set the paper properly.

Use the paper approved by

TOSHIBA TEC.

Re-adjust the sensor.

Replace the feed gap sensor or

black mark sensor.

Replace the take-up motor or

black mark sensor.

Install the cutter mechanism

properly.

Replace the stepping motor or

MAIN PC board.

Communication error. 1. Failure of the communication cable.

2. Failure of the RS-232C interface.

3. Failure of the communication

connector.

4. Failure of the PC or application

software.

5. Failure of the MAIN PC board.

Replace the cable.

Replace the serial I/F Board.

Replace the connector.

Modify the program.

Replace the MAIN PC board.