30

G8000 Series Installation and Operation Manual (380 V)

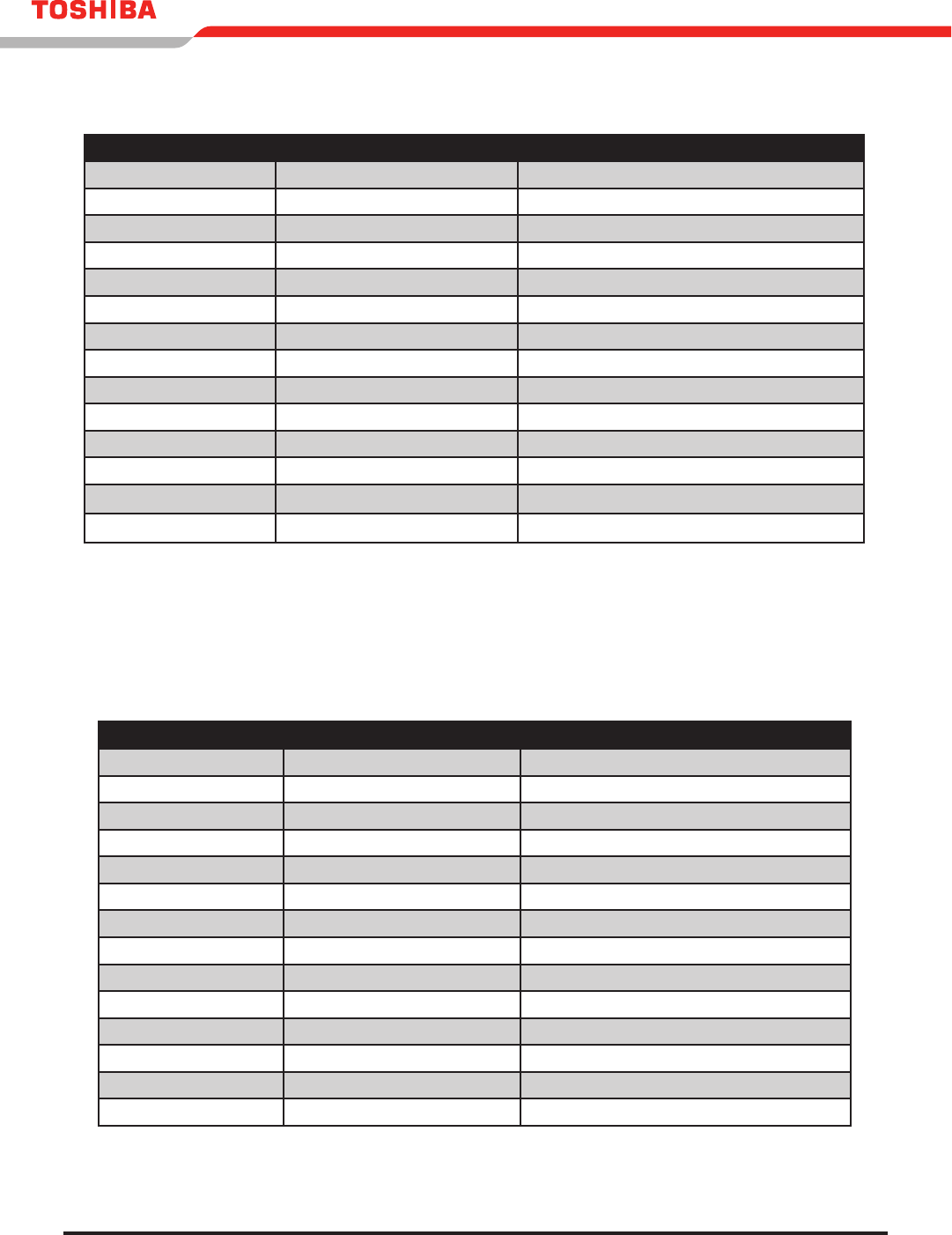

TABLE 11.2 RECOMMENDED CABLE SIZE AND FASTENER TORQUE FOR 120 KVA UNIT

(USE 75 °C COPPER WIRE)

Block Number Cable Size (Min-Max) Recommended Fastener Torque

2

1 (2) #1 – (2) 4/0 AWG 540 in.-lb. (61 N•m)

2 (2) #1 – (2) 4/0 AWG 540 in.-lb. (61 N•m)

3 (2) #1 – (2) 4/0 AWG 540 in.-lb. (61 N•m)

4 (2) #1 – (2) 4/0 AWG 540 in.-lb. (61 N•m)

5 (2) #1 – (2) 4/0 AWG 540 in.-lb. (61 N•m)

6 (2) #1 – (2) 4/0 AWG 540 in.-lb. (61 N•m)

7 (2) #1 – (2) 4/0 AWG 540 in.-lb. (61 N•m)

8 (2) #1 – (2) 4/0 AWG 540 in.-lb. (61 N•m)

9 (2) #1 – (2) 4/0 AWG 540 in.-lb. (61 N•m)

10 (2) #1 – (2) 4/0 AWG 540 in.-lb. (61 N•m)

11 (2) #1 – (2) 4/0 AWG 540 in.-lb. (61 N•m)

12

1

(3) 1/0 AWG – (2) 350 MCM 540 in.-lb. (61 N•m)

13

1

(3) 1/0 AWG – (2) 350 MCM 540 in.-lb. (61 N•m)

Flywheel Input (+)

3

(2) AWG 2/0 300 in.-lb. (33.9 N•m)

1

One battery string. (Consult factory if using more than one battery string.)

2

Fastener torque specied for: 1/2 in. diameter grade 5 steel bolt.

3

Per ywheel unit

TABLE 11.3 RECOMMENDED CABLE SIZE AND FASTENER TORQUE FOR 180 KVA UNIT

(USE 75 °C COPPER WIRE)

Block Number Cable Size (Min-Max) Recommended Fastener Torque

2

1 (3) #1 – (2) 4/0 AWG 540 in.-lb. (61 N•m)

2 (3) #1 – (2) 4/0 AWG 540 in.-lb. (61 N•m)

3 (3) #1 – (2) 4/0 AWG 540 in.-lb. (61 N•m)

4 (3) #1 – (2) 4/0 AWG 540 in.-lb. (61 N•m)

5 (3) #1 – (2) 4/0 AWG 540 in.-lb. (61 N•m)

6 (3) #1 – (2) 4/0 AWG 540 in.-lb. (61 N•m)

7 (3) #1 – (2) 4/0 AWG 540 in.-lb. (61 N•m)

8 (3) #1 – (2) 4/0 AWG 540 in.-lb. (61 N•m)

9 (3) #1 – (2) 4/0 AWG 540 in.-lb. (61 N•m)

10 (3) #1 – (2) 4/0 AWG 540 in.-lb. (61 N•m)

11 (3) #1 – (2) 4/0 AWG 540 in.-lb. (61 N•m)

12

1

(4) 2/0 AWG – (3) 250 MCM 540 in.-lb. (61 N•m)

13

1

(4) 2/0 AWG – (3) 250 MCM 540 in.-lb. (61 N•m)

Flywheel Input (+)

3

(2) AWG 2/0 300 in.-lb. (33.9 N•m)

1

One battery string. (Consult factory if using more than one battery string.)

2

Fastener torque specied for: 1/2 in. diameter grade 5 steel bolt.

3

Per ywheel unit