Xerox Nuvera™ 100/120 Digital Copier/Printer Customer Expectations Document

- 27 -

Printer Module

Xerographic monochrome (black and white) print engine. The printer utilizes a Discharged Area

Development (DAD) system, often referred to as “write black”.

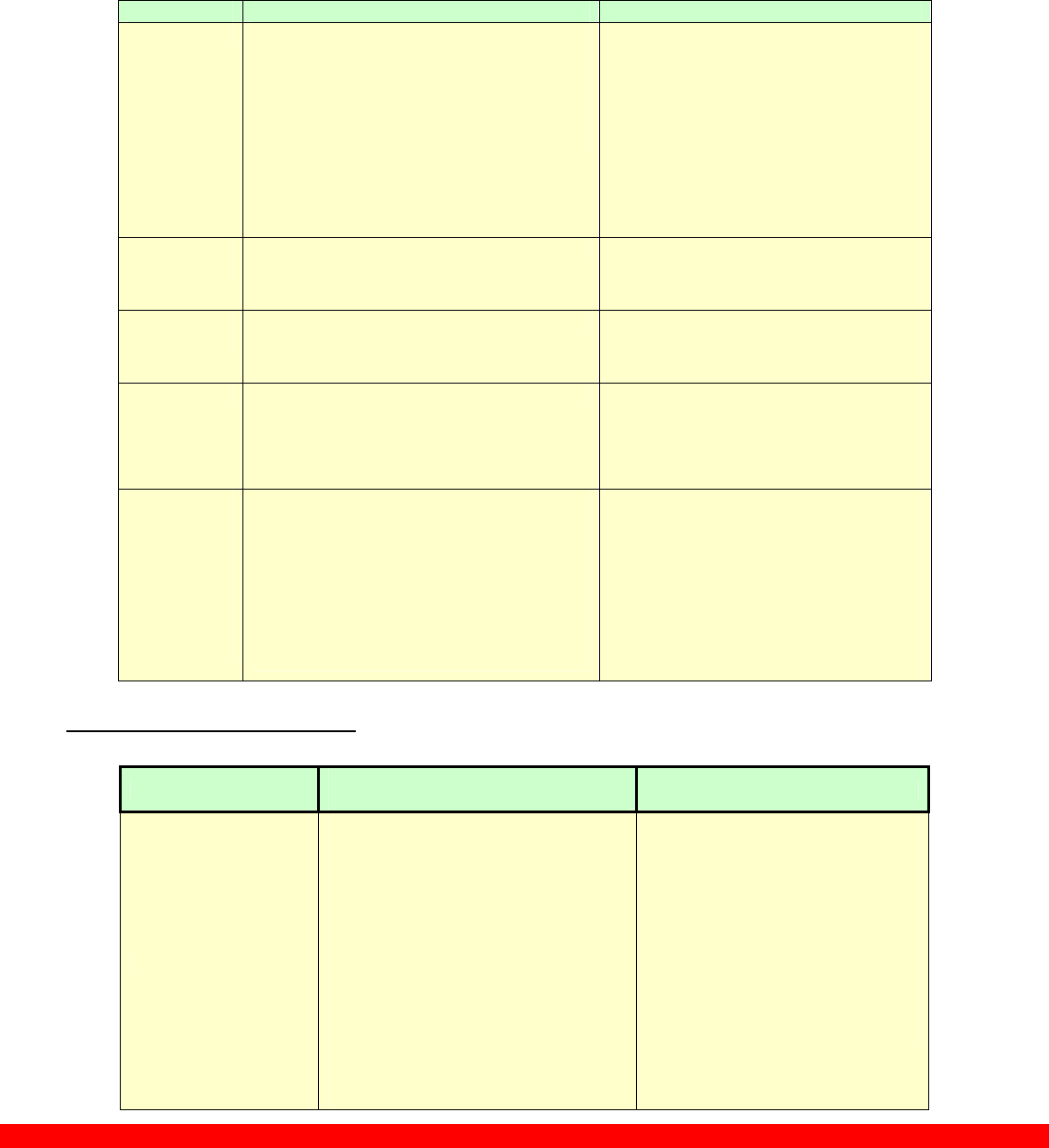

Item Xerox Nuvera™ 100/120 Digital Copier/Printer Comments

Image Format

• Maximum image area

12.6” x 18.5”

(320mm x 470mm)

• All sheets will have a default 3 mm (0.12 in.)

border without printing, regardless of sheet

size.

• Default border can be set to 0 mm, or

Lead Edge Erase only by the SA;

however some image quality degradation

may occur up to 6mm from the edge.

Also, some paper handling degradation

may occur, leading to an increase in the

number of jams.

Printer

Resolution

4800 x 600 dpi

No matter what resolution images are “ripped”

at, the printer uses hardware imaging process

to print them at 4800 x 600 dpi.

Fuser

Temperature

374° F (190° C) - when printing

Users may select enhanced permanence for

heavyweight paper by means of the User

Interface.

Registration Translating Electronic Registration Benchmark registration system holds image to

sheet alignment at +/- .65mm per side AND

front-to-back on Letter/A4 size papers;

+/- .75mm per side AND front-to-back on

Tabloid/A3 size papers.

Pitches on

Photoreceptor

Belt

Paper

dimensions

along process

direction

5 5.5” ≤ Paper Size ≤ 9.0”

(139.7mm ≤ Paper Size ≤ 228.6mm)

4 9.0” < Paper Size ≤ 11.7”

(228.6mm < Paper Size ≤ 297.2mm)

3 11.7” < Paper Size ≤ 17.0”

(297.2mm < Paper Size ≤ 431.8mm)

2 17.0” < Paper Size ≤ 18.5”

(431.8mm < Paper Size ≤ 469.9mm)

5 pitch mode produces 120 ppm (100)

4 pitch mode produces 96 ppm (80)

3 pitch mode produces 72 ppm (60)

2 pitch mode produces 48 ppm (40)

Image Quality Expectations

Image Quality Parameter

Xerox Nuvera™ 100/120 Digital

Copier/Printer

Comment

Image Uniformity

The Xerox Nuvera™ 100/120 Digital

Copier/Printer is designed to render tints

with a high degree of uniformity, and

produce vignettes, sweeps and gradients

that are smooth and even.

Sophisticated design prevents unwanted

process speed variations that plague

lesser digital printing systems with

banding problems.

Half-toning algorithms and customized

halftone dot designs take full advantage

of the printer’s high addressability

imaging system to render incredibly

sharp, detailed images.

The most discriminating judges of

print quality may occasionally

perceive a degree of mottle in large

uniform flat tints.

Extremely high humidity, low

document area coverage or papers

with poor formation can exacerbate

mottle.