CAUTION: Use only the cleaning agents indicated in the following table.

Zebra Technologies Corporation will not be responsible for any other fluids

being used on this printer.

Inconsistent print quality, such as voids in the bar code or graphics, may

indicate a dirty printhead. For best results, perform the cleaning procedures

in Table 4. For the location of these printer parts, refer to Figure 1 on page ii.

CAUTION! No lubricating agents of any kind should be used on this

printer! If used, some commercially available lubricants will damage the fin-

ish and mechanical parts.

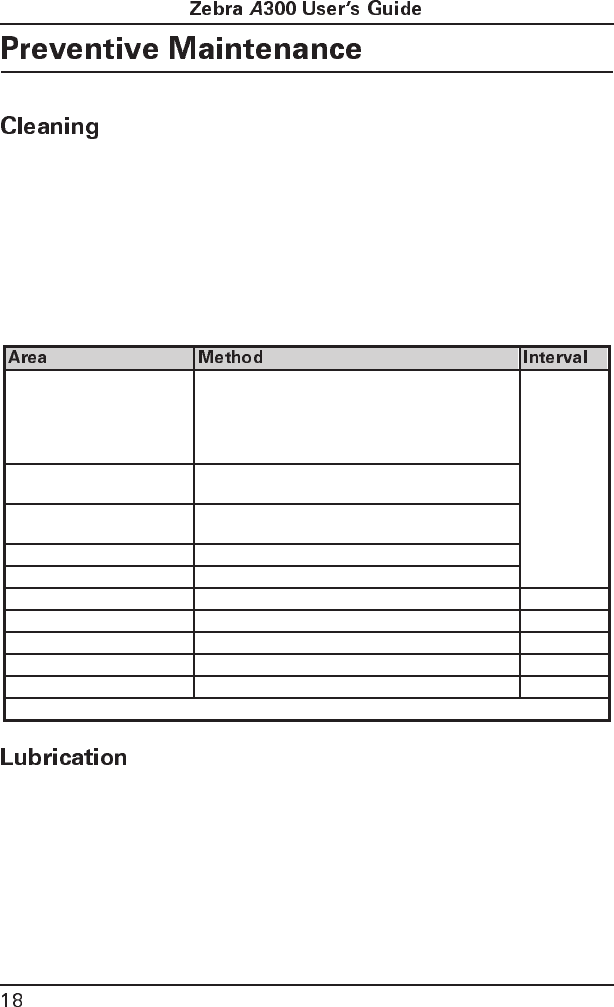

Table 3. Cleaning Schedule

Printhead Note: You do not need to turn the printer off

before cleaning the printhead. Use solvent* on a

cotton swab to clean the print elements from end

to end. (The print elements are the thin gray line

on the printhead.)

After every

roll of

media (or

500 ft of

fanfold

media)

Platen Roller Rotate the platen roller and clean it thoroughly

with solvent* and a cotton swab.

Peel-Off Roller Rotate the peel-off roller and clean it thoroughly

with solvent* and a cotton swab.

Transmissive Media Sensor Air blow

Media Path Solvent*

Peel/Tear Bar Solvent* As needed.

Label Available Sensor Air blow Monthly.

Printhead Open Sensor Air blow As needed.

Exterior Mild detergent or desktop cleaner. As needed.

Interior Brush/vacuum cleaner As needed.

* Zebra recommends using solvent containing 70% isopropyl alcohol.

55530lr4 Page 18 Wednesday, March 26, 1997 11:18 AM