CHAPTER 6 TROUBLESHOOTING

6-11

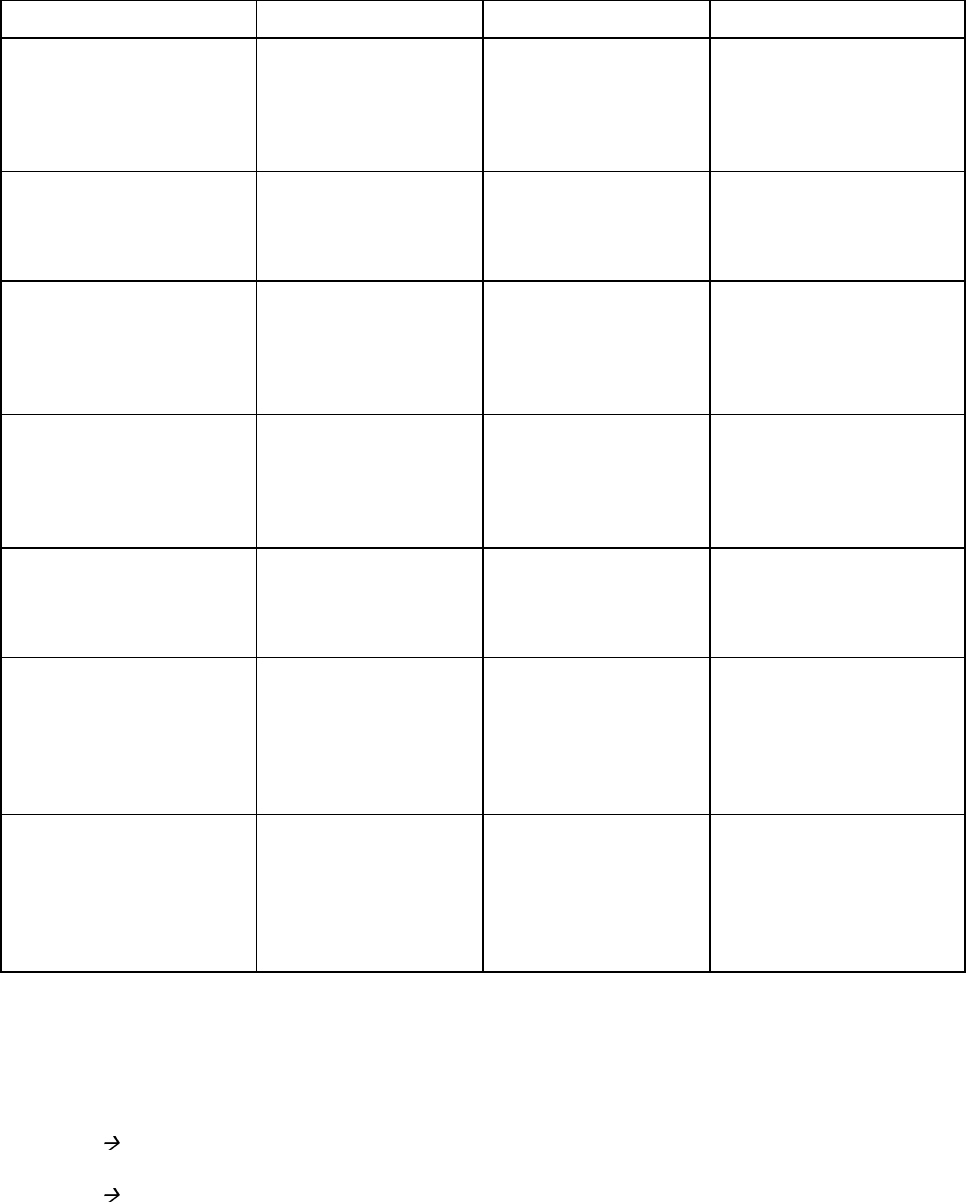

4.2.2 Causes & countermeasures

The causes for paper jam problems vary depending on the location of the paper jam. When a

paper jam occurs inside the printer, you have to find the location of the paper jam first, remove

the jammed paper and then take the appropriate countermeasure referring to the table below;

Problem Type of Jam Cause Remedy

Jam when the printer is

turned on.

Paper stuck The front registration

sensor or paper eject

sensor is turned on.

Remove the paper inside

the printer. If there is no

paper, check the suspect

sensors referring to

NOTE.

Top of paper stopped at

230mm from the second

exit roller. Next paper is

not fed.

Jam caused by paper

length detected as

longer than 400mm (16

in).

The front registration

sensor is not returning

properly and is not

turning off.

Check front registration

sensor motion referring to

NOTE.

Bottom of paper stopped

around the transfer roller.

Jam caused by paper

length detected as

shorter than 80mm.

The front registration

sensor was turned off

early. Malfunction of

actuator or hardware

noise.

Check the front

registration sensor

referring to NOTE.

Top of paper stopped

between the paper feed

roller and the pick-up

roller.

Jam caused by a

paper feed delay.

Paper was not fed in at

the proper timing due

to paper dust or wear

of the rubber pick-up

roller.

Remove the paper dust

attached to the pick-up

roller. If the rubber is

worn out, replace it with a

new one.

Top of paper stopped at

35mm from the contact

point of the heat roller and

pressure roller.

Jam caused by the

paper sensed as not

being ejected from the

paper eject sensor.

The paper eject sensor

is not working properly

and has not turned off.

(single printing)

Check sensor motion

referring to NOTE.

Top of paper stopped at

30 - 40mm from the

contact point of the heat

roller and pressure roller.

Jammed paper is not

printed at all.

Jam caused by

incorrect paper pick

up.

The surface of the

separation pad or the

pick-up roller is dirty or

worn out.

1) Clean the surface of

the separation pad or

pick-up roller.

2) Replace the separation

pad or pick-up roller.

Jam after paper is

ejected.

Jam caused by the

paper sensed as not

being ejected from the

paper eject sensor.

The paper eject sensor

or front registration

sensor is not working

properly and has not

turned off. (continuous

printing)

Check sensor motion

referring to NOTE.

NOTE:

How to check the sensors:

1) Turn off the printer power switch, open the front cover, and remove the drum unit.

2) Turn on the printer while pressing the control panel button. The Drum LED comes ON.

3) Lightly press the panel button again.

Alarm LED is ON = Front registration sensor is turned ON.

4) Press and release the panel button again.

Drum LED is ON = Paper eject sensor is turned ON.

For details on the sensors, see ‘Factory inspection mode’ in Subsection 10.2.