CHAPTER 6 TROUBLESHOOTING

6-18

6. MALFUNCTIONS

When taking countermeasures for malfunctions as described in this section, check connectors

for contact failure before measuring the voltage at the specified connector pins.

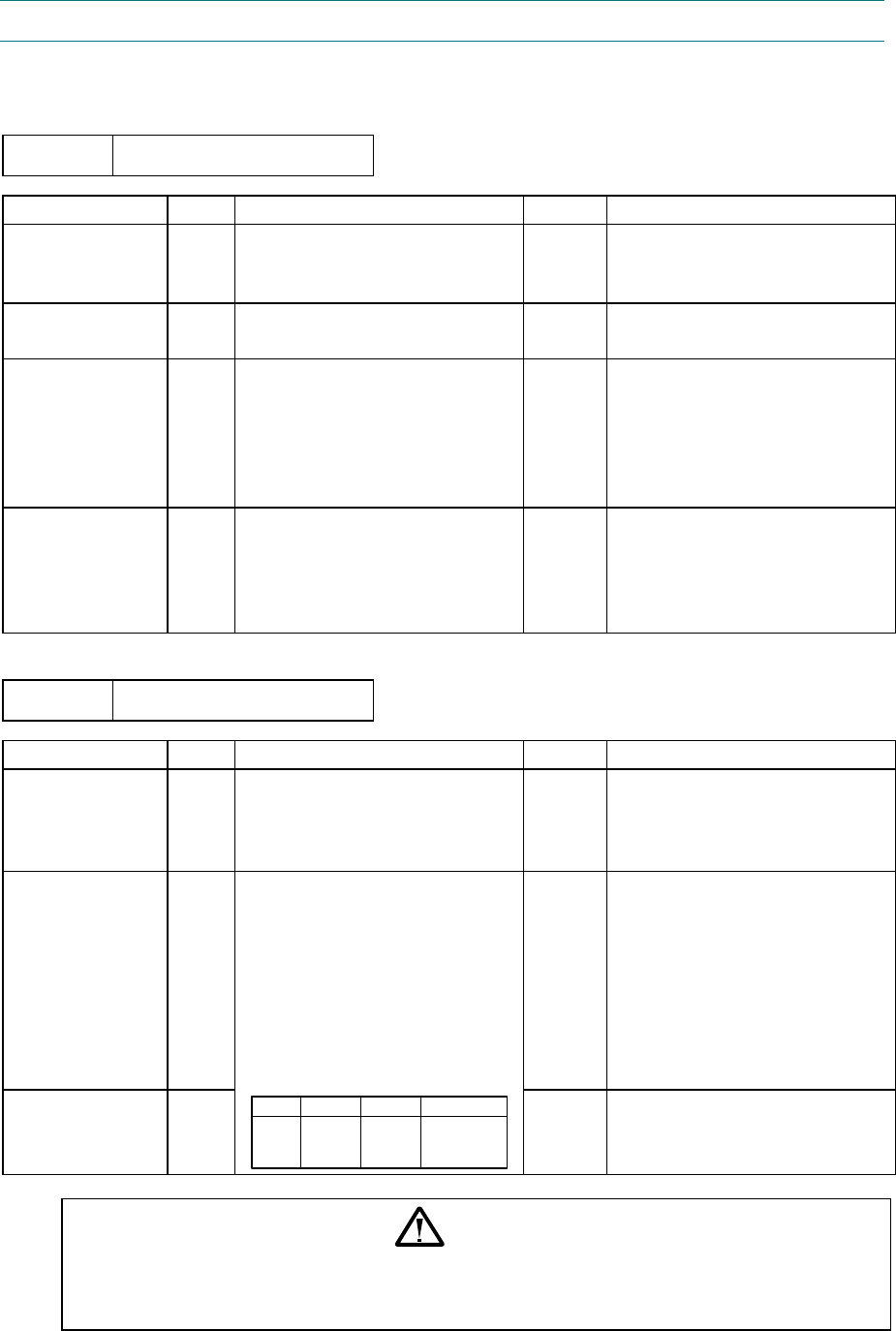

M-1 No AC power supplied

Possible cause Step Check Result Remedy

Supply voltage 1 Is the correct voltage present

at the outlet?

No Inform the user that the correct

voltage is not supplied at the

outlet.

Power plug 2 Is the power cord securely

plugged into the outlet?

No Plug the power cord securely

into the outlet.

Fuse (F1, F2) 3 Is the fuse blown? Yes If the fuse blows again

immediately after replacing the

low-voltage power supply PCB,

check that there is not a short

circuit somewhere in the AC

power supply line.

Wiring 4 Unplug the power supply plug.

Is there a broken wire between

the AC input connector of the

low-voltage power supply and

the power plug?

Yes Replace the AC power cord.

M-2 No DC power supplied

Possible cause Step Check Result Remedy

AC power

supply

1 Is AC power supplied between

connectors CN1-L and CN1-N

when the power plug is

plugged into the outlet?

No Follow the same check

procedure of M-1 “No AC

power supplied”.

Wiring, DC load 2 Turn off the power switch and

disconnect the P3 and P5

connectors on the engine PCB.

Turn on the power again.

Measure the voltages between

the terminals. Do the

measured voltage satisfy the

prescribed valued in the table

below?

Yes Turn off the power switch,

reconnect the connector and

turn the power switch on again.

If the protector circuit is

activated, check the connector,

the wiring from the connector,

and the DC load.

Low-voltage

power supply

PCB

3

PCB + lead pin - lead pin Voltage

Engine

P5-2 P5-3 Approx. 24V

P3-10

P3-9

Approx. 5V

No Replace the low-voltage power

supply PCB.

WARNING

If you analyze malfunctions with the power plug inserted into the power outlet, special

caution should be exercised even if the power switch is OFF because it is a single pole

switch.