II-27

2.2 Paper Transfer

2.2.1 Paper Supply

The pick-up roller picks up one sheet of paper from the paper feeder every time it is

rotated and feeds it to the paper feed roller.

Fig. 2-31

The paper is gripped between the pick-up roller and the separation pad and separated

into individual sheets.

The pick-up roller is directly connected to the sector gear, whose rotation is forcibly

stopped by the gear stopper. When the pick-up solenoid is activated, the clutch

mechanism is engaged by the solenoid action and the sector gear is driven; when it has

completed one full turn its rotation is stopped again by the gear stopper. The paper

drawn out by the pick-up roller pushes against the top of form sensor lever and the paper

top position/absence of paper is detected by sensing the motion of the lever.

2.2.2 Paper Registration

When paper picked up from the multi-purpose sheet feeder (MPF) pushes against the top

of form sensor actuator, the registration sensor lever is caused to turn, and the photo

sensor detects this motion. When this signal from the sensor is detected the paper feed

roller is stopped temporarily by the clutch. The paper is fed to the nip point between the

paper feed roller and the pinch roller in the multi-purpose sheet feeder, and the skew of

the paper is corrected by pushing the leading edge of the paper against the nip point.

When the paper feed roller starts to be rotated again when it is released by the clutch,

paper with the leading edge correctly aligned, is fed by the paper feed roller and is

transported to the transfer roller.

Clutch mechanism (engaged/released by the solenoid assembly)

Released when the solenoid is ON and engaged when the solenoid is OFF.

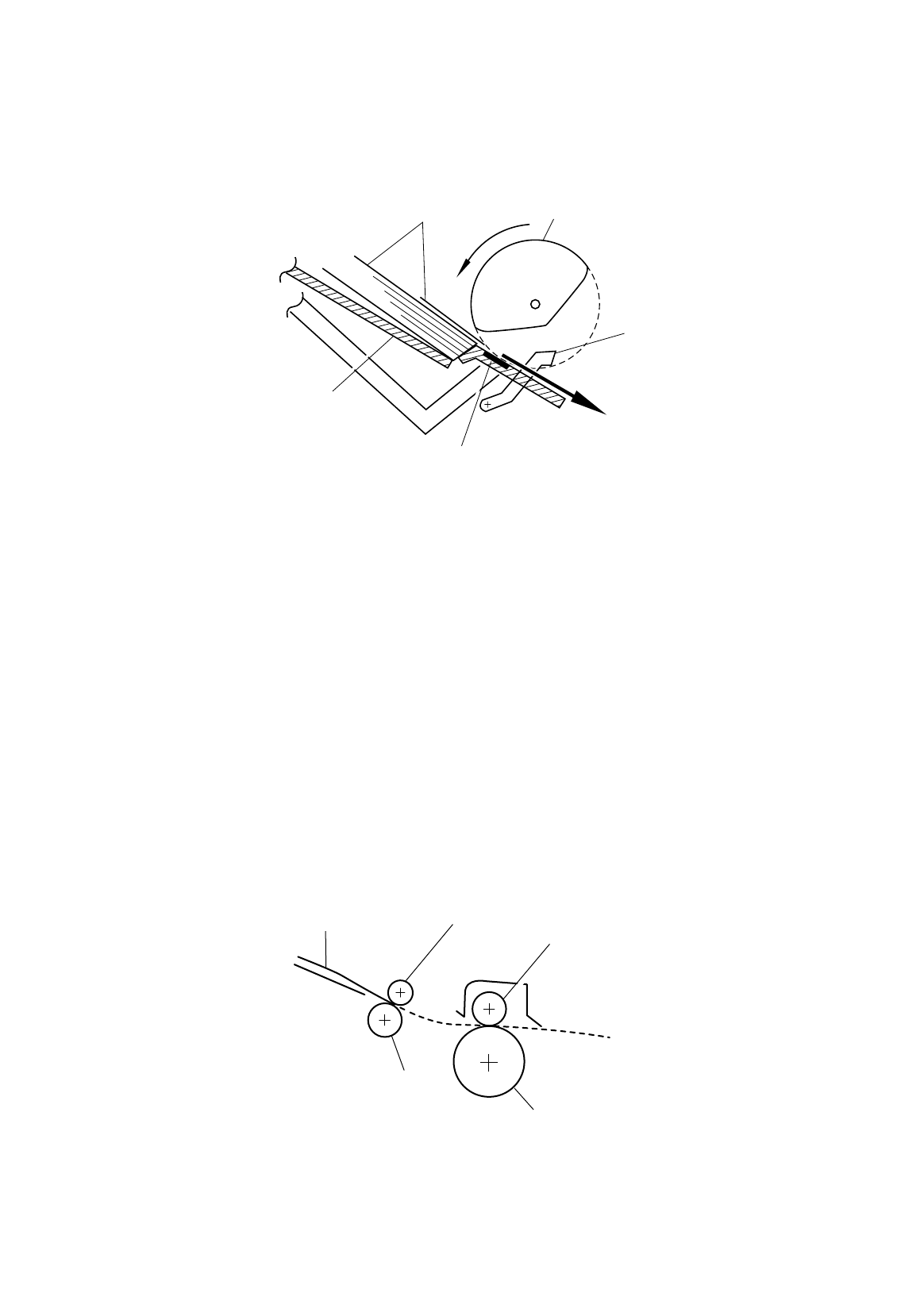

Fig. 2-32

Hopper plate

p

Pick-up roller

Registration sensor lever

Separation pad

Paper

Pinch roller

Transfer roller

Drum

Paper feed roller