Most paper jams can be avoided by correctly loading paper and specialty media in the printer.

The following hints can help prevent paper jams:

• Use only the recommended print media.

• Do not overload the print media sources. Make sure the stack height does not exceed the maximum height

indicated by the stack line on the labels in the sources.

• Do not load wrinkled, creased, damp, or curled print media.

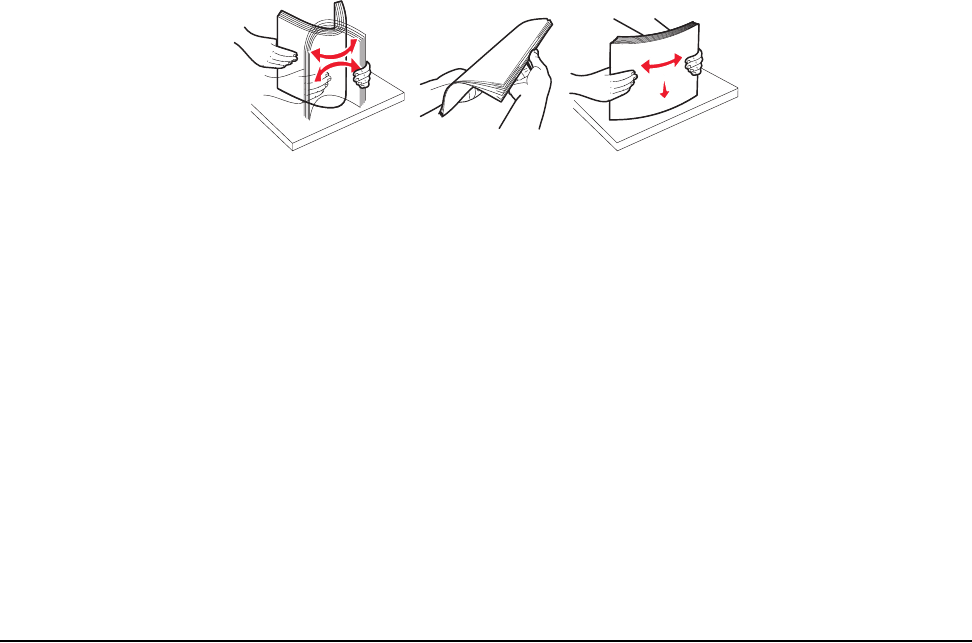

• Flex, fan, and straighten print media before loading it. If jams do occur with the print media, then try feeding

one sheet at a time through the manual feeder.

• Do not mix print media sizes, weights, or types in the same print media source.

• Push all trays in firmly after loading them.

Note: Make sure the media stack is below the maximum media fill indicators on the 250-sheet tray before

pushing the tray into the printer.

• Make sure paper guides are positioned before loading the paper or specialty media.

• Do not remove trays while a job is printing.

• Before loading transparencies, fan the stack to prevent sheets from sticking together.

• Do not use envelopes that:

– Have excessive curl

– Are stuck together

– Are damaged in any way

– Contain windows, holes, perforations, cutouts, or embossments

– Have metal clasps, string ties, or metal folding bars

– Have postage stamps attached

– Have any exposed adhesive when the flap is in the sealed position

printing environment.

Tools

The removal and adjustment procedures require the following tools and equipment:

• Spring hook

• Needle nose pliers

• Volt-ohmmeter

• #1 and #2 Phillips screwdriver

• Slotted screwdriver

1-8

•

Use only recommended media. Refer to the Card Stock & Label Guide available on the Dell Web site

at www.dell.com for more information about which media provides optimum results for the current