SECTION 3 TESTING & SERVICE

3-- 1

PREVENTIVE MAINTENANCE

Reasonable care in preventive maintenance will insure

high reliability and long life for the automatic tra nsfer

switch.

Operate the switch at least once a month.Performthis

four step Electrical Operation Test. This is a test with

load transfer.

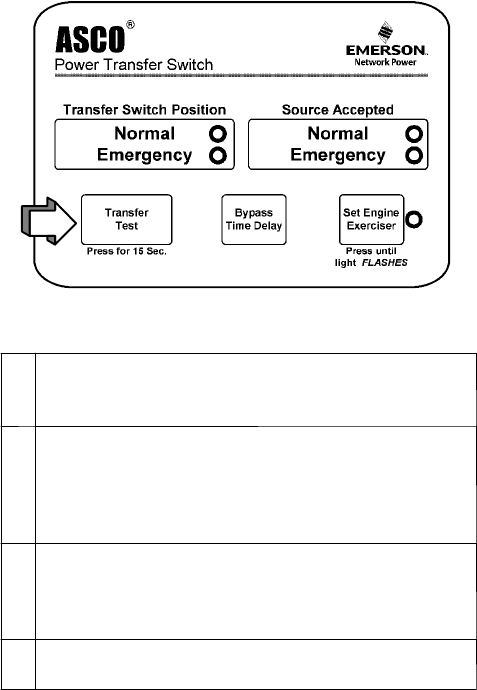

Transfer Switch Test

1. Press and hold the door-mounted TRANSFER

SWITCH TEST button until the engine starts and

runs. This should happen within 15 seconds.

2. The transfer switching device will operate to t he

Emergency position. If the Trans fer To E mer-

gencyDelayis used,the transfer willoccurafter

a t ime delay (up to 5 minutes). For immediate

transfer press BYPASS TIME DELAY button.

3. The transfer switching device will operate back

to Normal position after the Retransfer To Nor-

mal Delay (u p t o 30 minutes). For immediate

retransfer press BYPASS TIME DELAY button.

4. Unloaded Running (Engine Cooldown) Delay

allows engine to run unloaded for 5 minutes.

Clean and inspect the switch once a year. De-energize

all sources, then brush and vacuum away any excessive

dust accumulation. Remove the transfer switch barriers

and check contact condition. The non–replaceable main

contacts are designed to last the life of the transfer switch.

Reinstall the barr iers careful l y.

Maintain transfer switch lubrication.Thetransfer

switch has been properly lubricated, and under normal

operating conditions no further lubricating is required.

Renew factory lubrication if the switch is subjected to

severe dust or abnormal operating conditions.

Relub r icate t h e s o leno id operator if a c o il is re plac e d.

Do not use oil. Order lubrication 625550–001 (Castrol

EndurexR 4000 lubricant).

Replacement parts. Replacement parts are available in

kit form. When ordering parts provide the Serial No. and

Catalog No. from the transfer switch nameplate.

Contact your local ASCO Power Technologies sales

office.

DISCONNECTING THE CONTROLLER

The harness di sconnect plugs are furnished for repair

purposes only and should not have to b e unpl ugg ed. If the

controller must be isolated, follow these steps carefully.

Disconnecting the Plugs

1. Ob serve the position of the transfer switching device.

a. If the t ransfer switching device is in the Normal

position, place standb y engine starting control in the

off position. Then open the emergenc y source c ircuit

breaker.

b. If the transfer switching device is in the Emergency

position, open the normal source circuit breaker.

Place the engi ne starting control in the test or run

position.

2. Separate the quick disconnect plugs by sque ezing

the latches. Do not pull on the harness wires.

3. Label, remove, and tape the signal wires connected

to the engine start terminals on the transfer switch-

ing device: TB1 and TB3, or TB1 and TB2.

Reconnecting the Plugs

1. Ob serve the position of the transfer switching device.

a. If the transfer switch is in the Normal position, be

sure that the standby engine starting control is still

in the off position. The emergency source circuit

breaker still should be open.

b. If the transfer switch is in the Emergency position,

normal source circuit breaker still should be open.

2. Reconnect the signal wires connected to the

appropriate engine start terminals on the transfer

switch. See Section 1, Engine Starting Contacts.

3. The harness plugs and sockets are keyed. Carefully

align the plugs with the sockets and press straight in

until both latches click.

4. Restore the opposite source as follows:

a. If the transfer switch is in the Normal position,

place the standby engine starting control in the

automatic position. Then close the emergency

source circuit breaker.

b. IfthetransferswitchisintheEmergency position,

close the normal source circuit breaker. The load will

be automatically retransferred to the normal source

after the R etr a nsf e r to Norm a l Delay. For immediate

retransfer, press BYPASS TIME DELAY button.

Place the engine starting control in the autom atic

position.