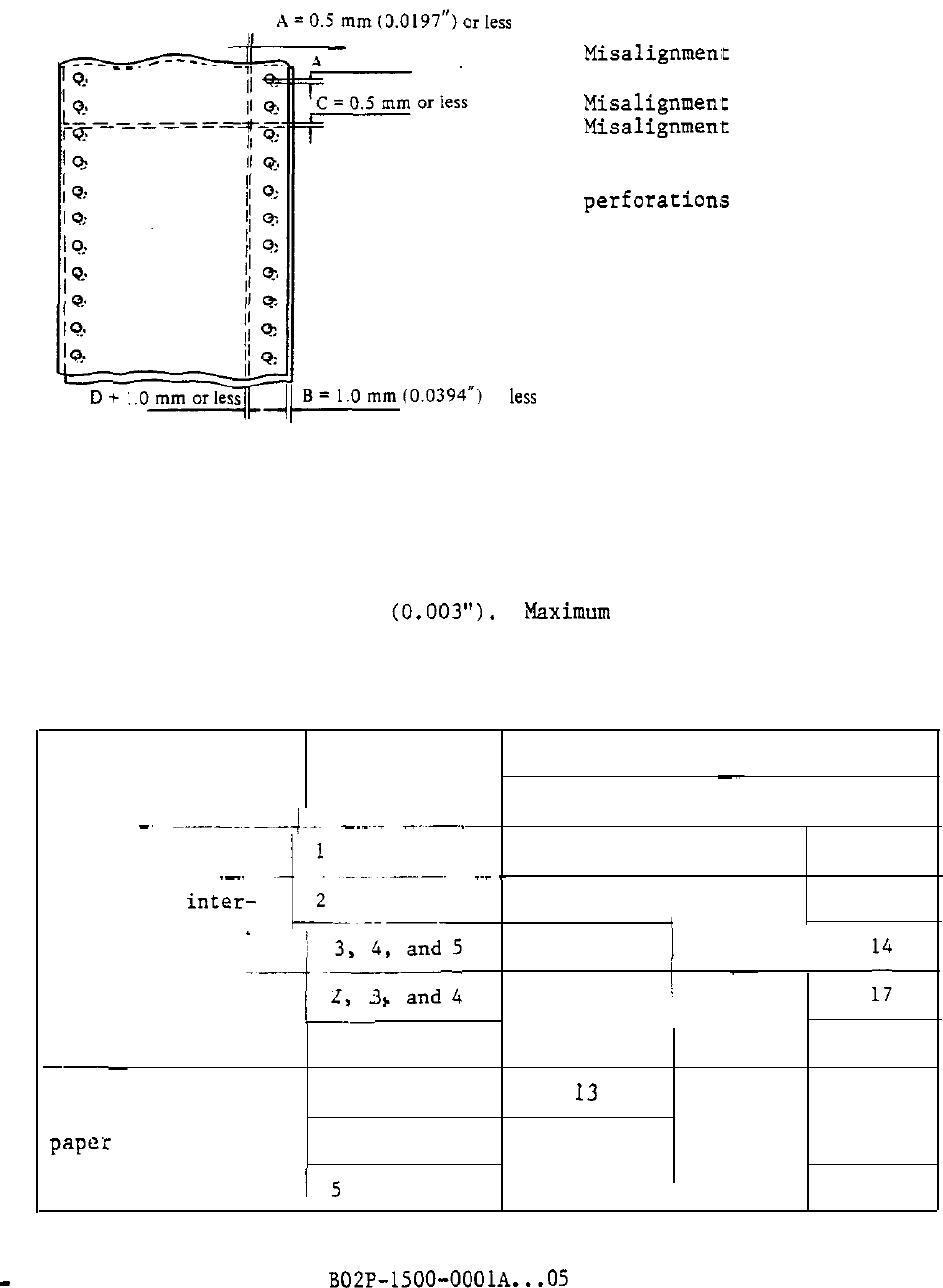

(2) Misalignment of paper

Misalignment between layers should be within the range shown in Figure

2.15.

= 0.5 mm or less

or

A:

B:

c:

D:

Misalignmen;t

of pin feed

holes

Misalignmen,t

of edges

MLsa1ignmen.t

of horizontal

perforations

Misalignment of vertical

perforatiom

less

Figure 2.15 Allowable incorrect alignment of multiple-part forms

(3) Thickness of parts

Thickness of parts should be uniform.

Thickness deviation in the print

area must be within 0.076 mm

(0.003").

Maximum total thickness of forms

(including edges) is 0.6 mm (0.0236"). Table 2.8 indicates recommended

bond weight of each layer according to forms type.

Table 2.8 Recommended bond weight of forms

Bond weight (pound/bond)

Forms type

No. of parts

-

-~

----...-~~-i.-

_..~~.

-~.~-.

Recommended

j

Minimum

I

Maximum

/

Single-part forms

1

--.

l-r--.

-~--

17 ~

15

28

Forms with

inter-

2

14 I

17

leaved carbon paper

4

.~-j

-=I;;

1

12.5

125 /

Carbon-backed forms

iL

'

)

-

:

:;

11

I 11

5

11

-~

Forms using

2 and 3

13

17

carbonless copy

paper

4

11

I5

11

11

2

-

16

B02P-1500-OOOlA...O5