ORCA-IV Image Transfer Laminator Operation Manual

Maintenance and Troubleshooting

© GBC Pro-Tech 1998 October

4-7

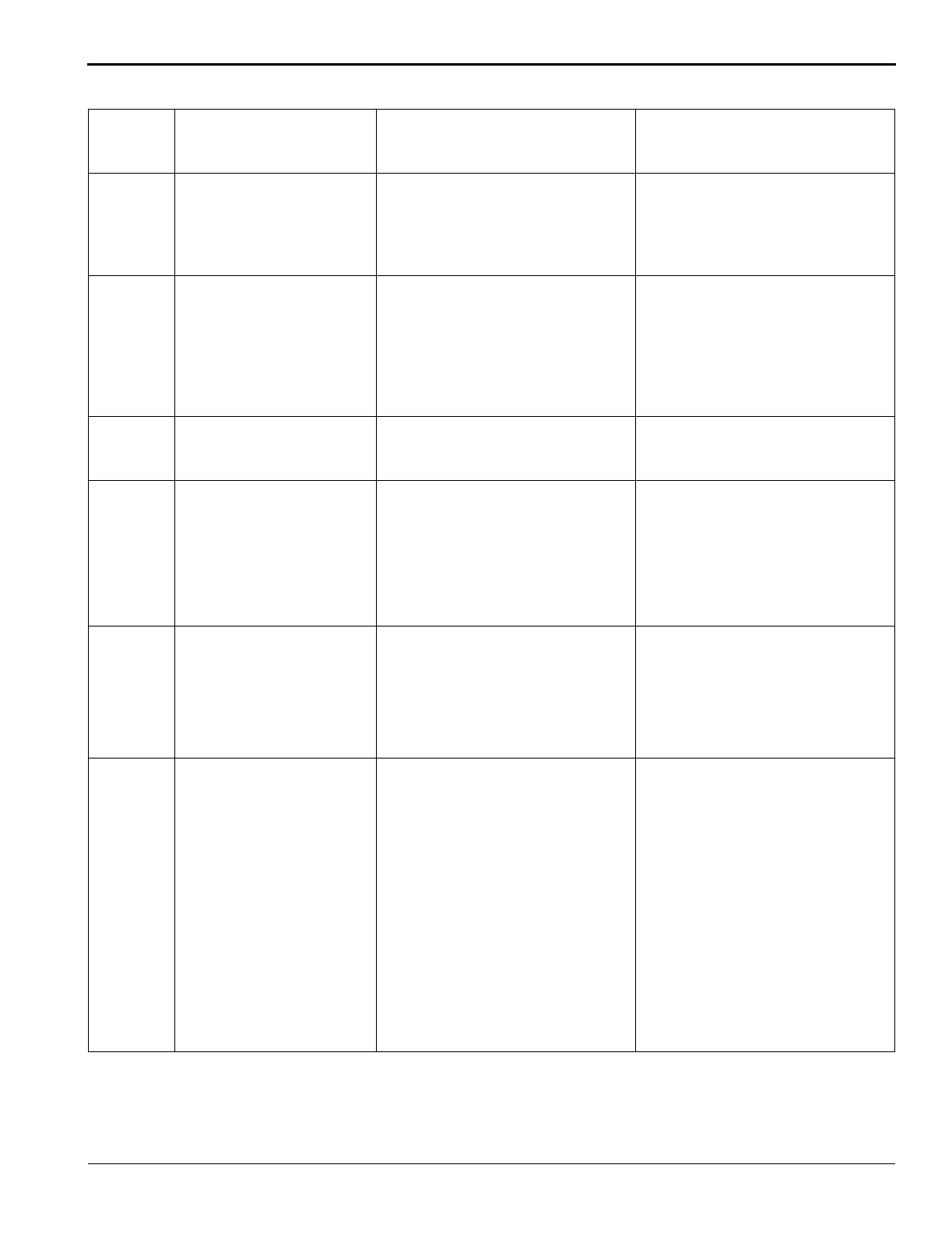

Table 4-4: Machine Troubleshooting Guide

Problem

Number

Problem

Possible Cause

Corrective Action

1 No display.

a. Is there power to the unit? a. Check for power to the machine

(building circuit breaker is on,

main switch is on (|), and the

machine circuit breaker is on

(up)).

2 Display reads 8888.

a. Is the machine reset? a. Make sure all safety buttons are

released (out). Be sure all kick

cables are reset and adjusted

properly. Press the machine reset

(above main switch). See

"Machine Reset Procedure" on

page 3-3.

3 Display reads .0 and the

machine does not run.

a. Is the direction indicator (FWD/

REV) pressed?

b. Is the speed not turned up?

a. Press FWD or REV.

b. Turn up the speed control.

4 Display missing the decimal

point (e.g. -reads 30 instead

of 3.0)

a. Is there a kick cable or safety but-

ton that has not been reset?

a. Make sure all safety buttons are

released (out). Be sure all kick

cables are reset and adjusted

properly. Press the machine reset

(above main switch).

See

"Machine Reset Procedure" on

page 3-3.

5 Display missing the decimal

point (e.g. -reads 30 instead

of 3.0) but the kick cables

and safety buttons have been

checked and the reset button

has been pushed.

a. Is the kick cable stretched out of

adjustment?

a. Verify that the kick cable is truly

resetting (listen, look). Adjust the

kick cable. See “Adjusting the

Kick Cable” on page 4-3.

6 Waiver on one side of paper/

vinyl.

a. Is the tension too low?

b. Does the roll lower unevenly?

c. Was there a misalignment on set

up?

d. Is there a bad roll of material?

e. Is the web loose only when first

starting or splicing?

f. Is there uneven nip pressure?

a. Increase appropriate brake ten-

sion.

b. Adjust cylinder flow controls.

c. Measure from the side frame to

the edge of material in front and

back to verify that the material is

webbed through straight.

d. Try a different roll.

e. Raise and lower the roll (pop up

and down) to pull the initial loose

web straight and tight.

f. Call Technical Support to disas-

semble and lubricate the cylinder

lift linkage (qualified service

technician required).